Footwear Manufacturing Cutting-4: Clicker Allowance & Pattern Scale Area Calculation

Estimated Reading Time: ~ 10 minutes

Introduction

In the earlier articles Leather Area Measurement, Discrepancy & Net Coefficient and Calculating True Leather Cost Using Cuttable Area, we established how leather quality is measured quantitatively and how those measurements translate into real material cost. In Leather Grading Systems & Vendor vs Factory Sorting, we explained how factories convert inspection data into internal grading systems.

This article takes the next logical step by explaining how graded leather data is converted into cutting standards through the calculation of clicker allowance. Clicker allowance represents the standard leather consumption for a defined cutting batch and forms the foundation for measuring cutting efficiency, material usage variance, and clicker performance.

1.Understanding Clicker (Cutter) Allowance

1.1 Definition

Clicker allowance is the standard quantity of leather required to cut a specific number of shoe pairs of a defined style, size mix, fitting, and leather type.

It is not an estimate or guess. It is a calculated standard derived from pattern geometry, leather characteristics, and quality coefficients.

1.2 Purpose of Clicker Allowance

Clicker allowance is used to:

- Establish cutting standards

- Measure leather usage variance

- Evaluate clicker performance objectively

- Control leather consumption

- Support incentive or feedback systems

Without a defined allowance, cutting efficiency cannot be measured accurately.

2. Components of the Clicker Allowance System

The system for calculating clicker allowance consists of the following sequential steps:

- Measuring the scale area of the pattern

- Adjusting for second waste

- Adjusting for leather type

- Adjusting for shoe size and fitting

- Adjusting for area discrepancy and cuttability

- Calculating final clicker allowance

Each step must be applied in the correct order.

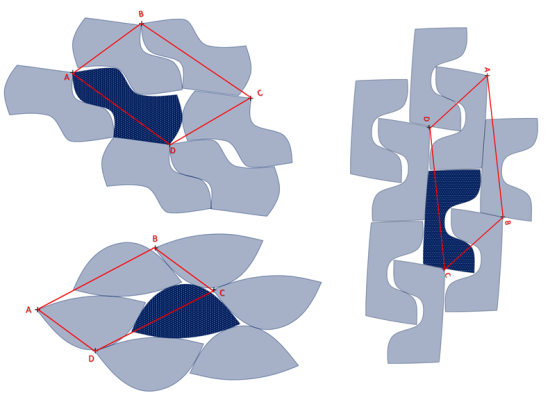

3. Measuring the Scale Area of the Pattern

3.1 Objective

The objective of scale area measurement is to determine the parallelogram area obtained from optimal pattern layouts. This area includes:

- Net pattern area

- First waste (interlocking waste)

Scale area is the base value for all further calculations.

3.2 Method of Measurement

- Select prominent edge points on each pattern piece

- Place the pattern on graph paper aligned with the working direction

- Draw the outline directly under the pattern edge

- Repeat pattern placement to achieve minimum interlocking waste

- Construct a parallelogram by joining corresponding points

- Calculate area using:

Scale Area = Base × Height

This process must be repeated using alternative layouts to ensure minimum waste.

4. Pattern Scale Area Form

Table 4 – Pattern Scale Area Form

| Pattern Item | Base | Height | Scale Area (Sq.ft / pair) | Pieces per Pair |

|---|---|---|---|---|

| Cap Toe | 0.82 | 0.26 | 0.2132 | 2 |

| Vamp | 0.93 | 0.48 | 0.4464 | 2 |

| Lateral Quarter | 0.82 | 0.45 | 0.3690 | 2 |

| Medial Quarter | 0.82 | 0.46 | 0.3772 | 2 |

| Tongue | 0.32 | 0.32 | 0.1024 | 2 |

Total Pattern Scale Area per Pair = 1.5082 Sq.ft

5. Adjusting for Second Waste

5.1 Objective

Second waste represents leather loss occurring near the edges of the skin due to shape limitations. This waste depends on:

- Average skin size

- Average pattern size

5.2 Calculating Average Scale of the Pattern

Average Scale = Scale Area per Pair ÷ Number of Pattern Pieces per Shoe

Example:

- Scale area per pair = 1.5082 sq.ft

- Pattern pieces per shoe = 5

Average Scale = 0.3016 sq.ft

5.3 Determining Second Waste Percentage

Using the second waste chart:

- Average scale = 0.3016 sq.ft

- Average skin size = 15 sq.ft

Second Waste Percentage = 22.5%

Table 5 – Basic Allowance Calculation

| A. Scale Area per pair (from table 4) | 1.5082 Sq.ft | |||

| B. Number of pattern pieces per one shoe (from Table 4) | 5 Pieces | |||

| C. Average scale of the pattern A/B = 1.58/5 = | 0.3016 Sq.ft | |||

| Sq,ft | Sq.ft | Sq.ft | Sq.ft | |

| D Average Size of the Skin | 3 | 5 | 10 | 15 |

| E Second Wastage % (from Table 6) | 30.50% | 26.5% | 23.5% | 22.5% |

| F Second Waste (E/100)* A= | 0.4600 | 0.4000 | 0.3544 | 0.3394 |

| G Basic Allowance A+F | 1.9682 | 1.9082 | 1.8626 | 1.8476 |

6. Adjusting for Leather Type

Each leather type has unique shape, fiber structure, and defect distribution. To reflect this, leather coefficients are applied.

Adjusted Allowance = Basic Allowance × Leather Coefficient

This step normalizes allowance values across different leather articles.

7. Adjusting for Shoe Size and Fitting

Leather consumption varies with shoe size and fitting width. Therefore, allowance must be adjusted using size and fitting coefficients.

Weighted Average Size Calculation

Example:

- Sizes and pairs: 7/12, 8/12, 9/36, 10/30

- Weighted sum = 804

- Total pairs = 90

Weighted Average Size = 804 ÷ 90 = 8.93 ≈ Size 9

Corresponding coefficients are applied from size and fitting tables.

8. Adjusting for Area Discrepancy and Cuttability

The final adjustment uses the standard net coefficient derived from leather inspection and grading.

This step ensures that allowance reflects:

- Area shortfall

- Defect levels

- Overall leather usability

Factories that rely solely on vendor grading often experience higher waste and inconsistent results.

9. Clicker Allowance Calculation Form

Table 7 – Clicker Allowance Form (Summary)

| Description | Value |

| Basic Allowance | 1.8476 |

| Leather Coefficient Applied | 1.02 |

| Size/Fitting Adjustment | Applied |

| Standard Net Coefficient | As defined |

| Final Allowance per Pair | Calculated |

This allowance is multiplied by batch pair quantity to obtain the standard cuttable area allowance.

Conclusion

Clicker allowance calculation converts pattern geometry, leather characteristics, and quality coefficients into a measurable cutting standard. It bridges the gap between technical pattern design and shop-floor performance control.

In the next article of this series, Clicking Performance & Material Usage Analysis, the discussion will focus on how actual leather usage is compared against clicker allowance to measure favorable or unfavorable performance, and how this information supports cutting efficiency improvement and management decision-making.