Welcome to The FootwearEdge

We are your dedicated resource for Global Footwear Industry Analysis. Our platform bridges the gap between industry professionals, learners, and enthusiasts. Are you a student, a factory technician, or a designer? If so, you will find valuable insights here..

-

Complete Footwear Pattern Grading Guide: Co-ordination, Straight Grading, Hand Grading and Machine Grading Explained

Introduction — The Engineering Behind Footwear Size Development Footwear grading is one of the most technically sensitive operations in shoe manufacturing. While grading is often described as enlarging patterns across sizes, in reality it represents a controlled engineering system linking last design, upper development, tooling investment, and production efficiency. Every size must preserve the design intention of the model shoe while fitting its corresponding last accurately. If grading principles are misunderstood, factories experience problems such as distorted uppers, lasting difficulty, inconsistent heel proportions, or excessive tooling costs. Historically, grading methods…

-

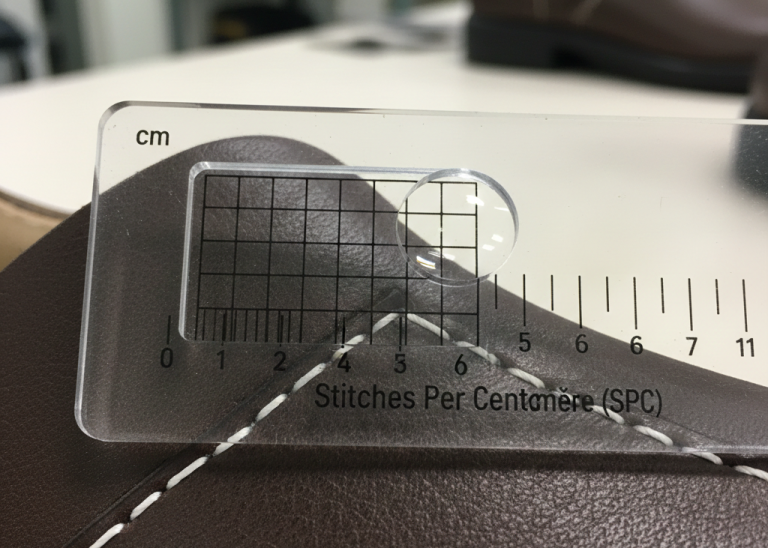

Footwear Manufacturing Insights: Girths, Sizes, and Measurement Standards for the USA Market

For footwear factories exporting to the United States, understanding shoe sizing alone is not sufficient. Equal importance must be given to girth classification, as the US market demands multiple width options across the same size range. When girth control is…

-

Footwear Manufacturing Process: Heat Setting in Full Shoe Assembly — Properties, Requirements and Process Control

Heat setting forms a critical stabilization stage in the footwear manufacturing process. During lasting, operators stretch the upper over the last and force flat materials into a complex three-dimensional geometry. However, the upper does not automatically retain this shape. Internal…

-

Footwear Manufacturing Insights: Metal Caps and Heel Pitch Checking in Last Engineering

Within footwear manufacturing, many fit and durability issues originate not from materials themselves, but from small engineering decisions made during last development and upper design. Among these, the correct application of metal toe caps and the accurate checking of heel…

-

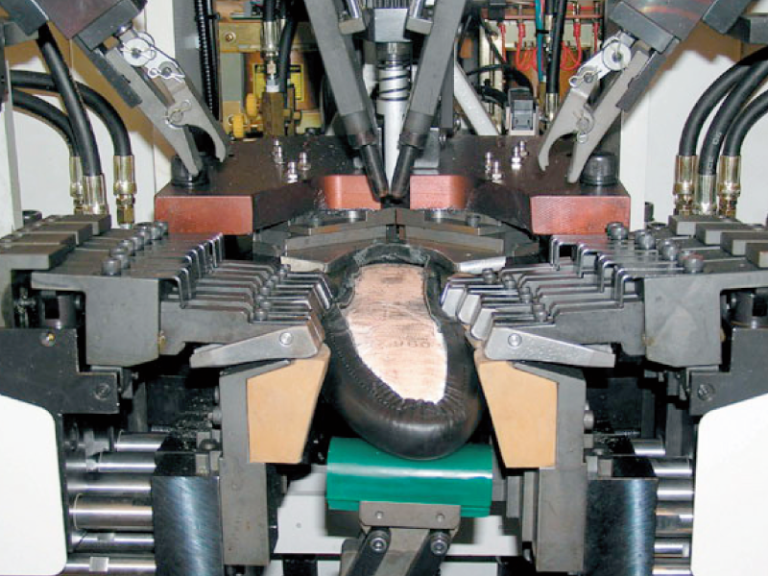

Lasting in Footwear Manufacturing: Principles, Methods, Shape Retention, and Modern Technological Practices

Introduction to Lasting in Footwear Manufacturing Lasting is defined as the process in which the upper is stretched, shaped, and secured over the last so that it accurately adopts the form intended by the designer. During this operation, the upper…

-

Hand Lasting in Footwear Manufacturing: Traditional Techniques, Drafting Control, and Structural Precision

Introduction to Hand Lasting in Footwear Construction In traditional footwear manufacturing, hand lasting represents the original and most fundamental method by which uppers are shaped and secured to the last. Historically, lasting machinery evolved through attempts to replicate the precise…

-

The Complete Guide to Moccasin Shoemaking: Types, Factory Processes, and Handcrafted Luxury Techniques

Introduction to Moccasin Construction and Historical Context Moccasins rank among the most enduring and comfortable footwear designs ever created. Indigenous traditions originally shaped them to prioritize natural foot movement, flexibility, and minimal structure. Over centuries, artisans have evolved these humble…