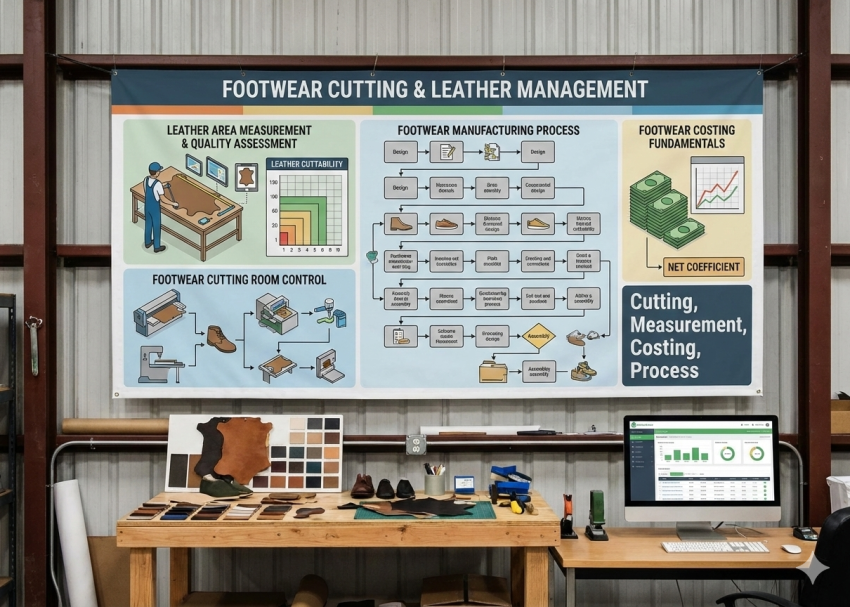

Footwear Manufacturing Cutting : Leather Area Measurement, Discrepancy & Net Coefficient

Estimated Reading Time: ~ 5 minutes

Introduction

In footwear manufacturing, leather is the single largest material cost component in most upper constructions. Even a small variation in leather area, defect level, or cutting yield can significantly affect product cost, profitability, and vendor performance evaluation. For this reason, systematic measurement of leather area, cuttability, and net coefficient is a critical responsibility of the cutting and material control functions.

This content explains, step by step, how to measure area discrepancy, cuttability, and how to calculate the net coefficient, using structured methods commonly applied in professional footwear factories.

1. Leather Area Discrepancy

1.1 Objective of Area Discrepancy Measurement

Leather received from the tannery may be larger or smaller than the area stated on the invoice. Since leather is purchased on area basis (square feet or square decimeters), any discrepancy directly impacts material cost. Therefore, checking area discrepancy is an essential part of incoming leather inspection.

The purpose of this measurement is to:

- Verify vendor-declared leather area

- Establish factual data for cost control

- Create a base for net coefficient calculation

1.2 Sample Size for Area Measurement

- Select 5–15 skins per leather article

- Selection must be random

- Upper and lining leathers must be assessed separately

1.3 Methods of Measuring Leather Area

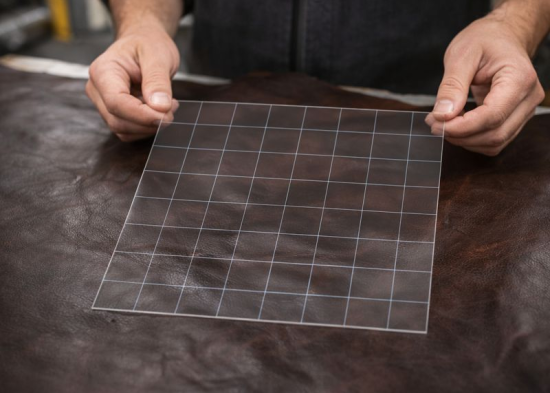

a) Grid Method

A transparent plastic grid divided into 1 sq.ft squares, each further subdivided into 1/100 sq.ft, is placed over the leather skin.

- Count full squares

- Estimate partial squares

- Preferably use a grid larger than the skin

This method is simple, visual, and reliable for audit checks.

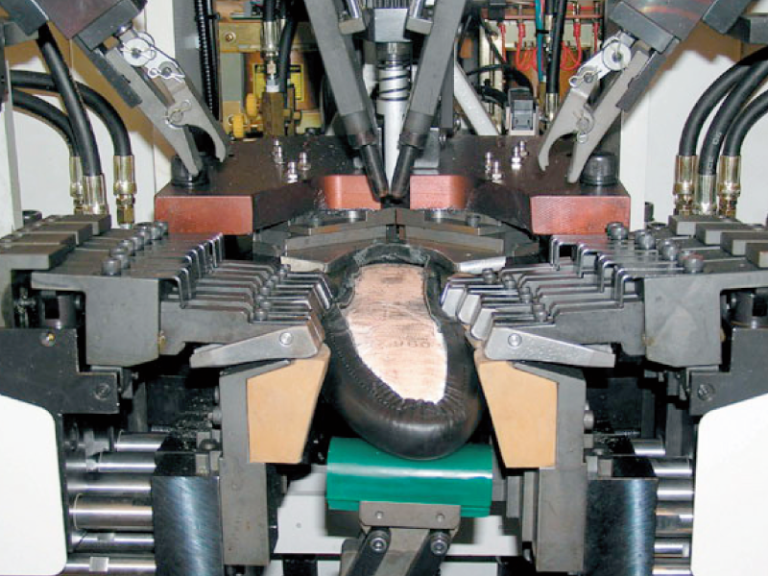

b) Machine-Based Measurement

Leather area may also be measured using:

- Area scanners

- Planimeters

- Digital leather measuring machines

Since machine accuracy can vary, periodic cross-checking using the grid method is strongly recommended.

1.4 Recording and Calculating Area Discrepancy

The results are recorded in the Net Coefficient Report and used to calculate the Area Discrepancy Coefficient (E).

E = B / A

- A = Total area stated by the vendor

- B = Total area measured by the factory

Example: If leather is 3% short on area, the coefficient becomes 0.97 (E)

2. Measuring Cuttability of Leather

2.1 Objective of Cuttability Assessment

Tanneries usually grade leather as A, B, C, or D. However, grading standards may differ between vendor and factory. To ensure consistency and cost accuracy, the factory must independently assess cuttability for each shipment.

Cuttability measures how much of the leather area can actually be converted into usable shoe components.

2.2 Sample Size for Cuttability

- Select 10–15 skins randomly

- The same skins used for area measurement may be reused

2.3 Identifying Uncuttable Areas

- Mark defects using silver pen, chalk, or white pencil

- Assume a standard shoe style for evaluation

Standard Shoe Definition (Example):

- Two quarters

- Derby shoe

- Components per shoe:

- Vamp with tongue

2.4 Measuring Uncuttable Area

- Measure marked uncuttable zones using a 1 sq.ft transparent grid

- Record values skin-wise

2.5 Calculating Cuttability Coefficient (F)

Formula:

F = (B − C) / B

- B = Measured area

- C = Uncuttable area

This coefficient expresses the usable percentage of leather.

3. Net Coefficient

3.1 Objective of Net Coefficient

Area discrepancy and cuttability independently describe leather quality. However, for clear decision-making, both must be combined into a single performance indicator called the Net Coefficient (G).

3.2 Net Coefficient Formula

G = E × F

- E = Area discrepancy coefficient

- F = Cuttability coefficient

The net coefficient represents the true usable proportion of purchased leather.

4. Net Coefficient Report

Table 1 – Net Coefficient Report

| A | B | E | C | D | F | |

| Sample Skin No | Leather area stated be vendor | Leather area measured by shoe factory | Area discrepancy coefficient (b/a) | Uncuttable area measured by shoe factory | Cuttable area (b-c) | Cuttability coefficient (b-c)/b |

| Sq.ft | Sq.ft | Sq.ft | Sq.ft | |||

| 1 | 10.00 | 9.25 | 0.93 | 2.00 | 7.25 | 0.78 |

| 2 | 10.25 | 9.61 | 0.94 | 1.84 | 7.77 | 0.81 |

| 3 | 9.50 | 9.03 | 0.95 | 2.12 | 6.91 | 0.77 |

| … | … | … | … | … | … | … |

| Total 101.25 A | Total 95.00 B | E=0.9383 B/A = E | Total 16.60 C | 78.41 D= B-C | F = 0.82528 D/B = F | |

Net Coefficient (G) = E × F = 0.77

Note: Skin-by-skin coefficient calculation is not mandatory unless frequency distribution analysis is required.

5. Practical Interpretation of Net Coefficient

- A low net coefficient indicates high waste or poor vendor consistency

- A high net coefficient reflects stable leather quality and better cutting yield

Factories may:

- Compare vendors objectively

- Set acceptance thresholds

- Use data for cost negotiation

6. Concept of Leather Area

Area is a two-dimensional measurement, unlike length which is linear.

Key conversions:

- 1 sq.dm = 0.1076 sq.ft

- 1 sq.ft = 9.29 sq.dm

Understanding area measurement fundamentals is essential for accurate leather costing.

Conclusion

Accurate measurement of leather area discrepancy, cuttability, and net coefficient forms the foundation of effective cutting control in footwear manufacturing. These calculations convert subjective quality perceptions into quantitative, auditable data, enabling better purchasing decisions, cost transparency, and operational discipline.