Toe Puff and Stiffeners: Materials, Types, Manufacturing, and Performance Control in Footwear

Introduction to Toe Puff and Stiffeners in Footwear Construction

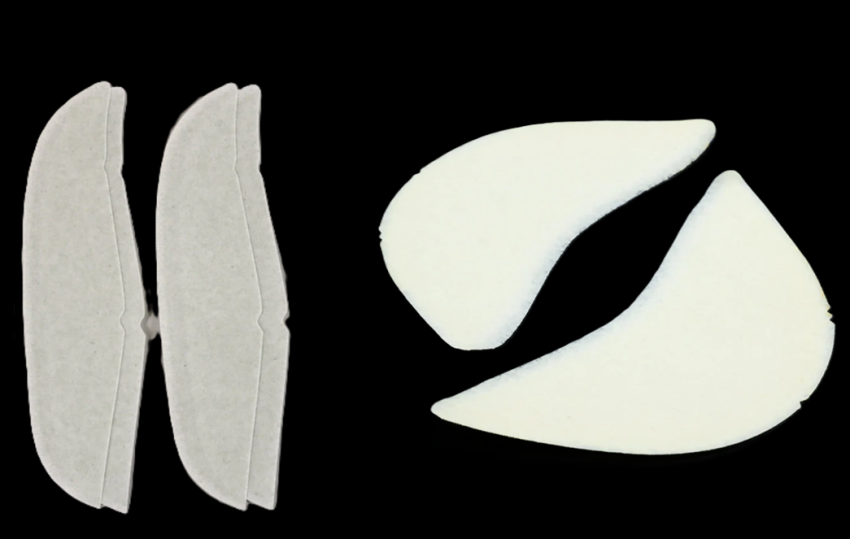

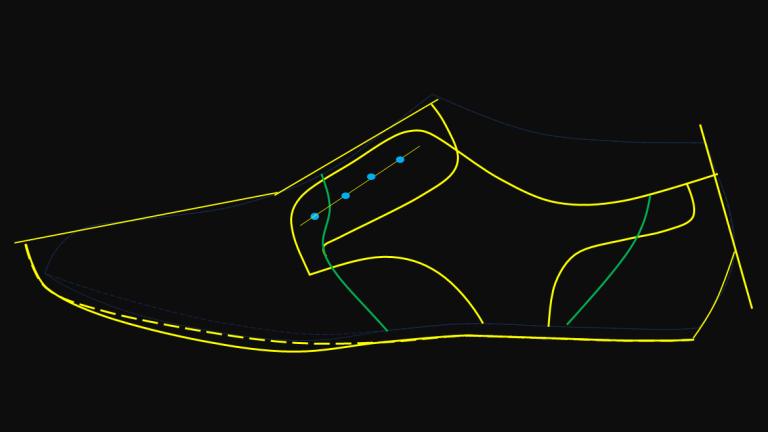

Toe puff and stiffeners are reinforcing components incorporated into footwear uppers during manufacture to preserve last shape, maintain dimensional stability, and retain the original aesthetic appearance of the shoe. While toe puffs reinforce the toe end of the upper, stiffeners retain shape and provide structural support at the back part of the shoe.

Because footwear styles range from lightweight fashion shoes to heavy-duty industrial boots, the functional demands placed on toe puff and stiffeners vary significantly. Therefore, manufacturers employ a wide range of reinforcement materials to meet both performance and aesthetic requirements.

In addition, differences in manufacturing techniques, upper materials, and end-use conditions require reinforcement materials with distinct mechanical and processing properties. As newer materials emerge, innovation in toe puff and stiffeners continues to focus on delivering reliable reinforcement at the lowest possible cost while maintaining consistency in mass production.

This article first considers the different types of toe puff and stiffeners, excluding steel toe caps and fibreboard stiffeners, and then examines their materials, manufacturing processes, properties, recommended uses, and quality risks.

Historical Development of Toe Puff and Stiffener Materials

Classifications of toe puff materials show a clear progression from traditional natural materials to modern polymer-based systems. Each material reflects the technological capabilities and footwear requirements of its era.

Traditional and Early Materials Used for Toe Puffs

Leather produces a strong and durable toe puff but remains relatively bulky. Manufacturers must thoroughly wet leather to achieve sufficient pliability, and the long drying time limits production efficiency.

Leatherboard offers more uniformity than leather; however, it remains bulky and adds stiffness that can be excessive for modern lightweight footwear.

Historically, factories used pre-formed leather layers, but these proved expensive, inconvenient, and messy in production environments.

Celluloid toe puffs provided sleek and firm reinforcement. However, the complex preparation process limited their suitability for high-volume manufacturing.

Nitrocellulose-impregnated fabrics retained the advantages of celluloid puffs while being easier to handle and more adaptable to factory processes.

Modern Toe Puff Material Systems and Their Properties

Paint-On Toe Puff Systems

Paint-on toe puff materials are inexpensive but often messy and highly variable in performance. Their performance depends strongly on penetration depth and controlled resin application.

They are mainly associated with lightweight footwear, such as veldtschoen sandals, where only minimal toe reinforcement is required. Shellac or celluloid solutions are typically used. However, contamination of the upper material and inconsistent adhesion to the last remain common production issues.

Thermosetting Toe Puff Systems

Thermosetting toe puffs are messy to use and carry risks of dermatitis due to chemical exposure. They produce extremely hard puffs, which may reduce comfort in many footwear applications.

Impregnated Fabric Toe Puffs (Heat- and Solvent-Activated)

Impregnated fabric toe puffs are clean and relatively easy to apply. When manufacturers properly control bonding and activation operations, these materials produce reliable results across most shoe types. However, overall performance depends heavily on consistent process control.

Two main types of impregnated toe puff fabrics are used today, differing primarily in their activation mechanism.

Thermoplastic (Heat-Activated) Toe Puffs

Thermoplastic toe puffs soften when heated and become sufficiently extensible and malleable to accept pulling-over and lasting operations. As a result, these materials dominate modern footwear production due to their clean handling, ease of control, and consistent performance

Solvent-Activated Toe Puffs

Solvent-activated toe puffs are softened in the factory using solvent dipping or conditioning machines. The solvent makes the material receptive to shoemaking operations.Some materials allow either heat or solvent activation, offering flexibility in manufacturing.

Fabric Structures Used in Impregnated Toe Puffs

The same base fabrics are used for both solvent-activated and heat-activated toe puffs, including woven, non-woven, needle-punched, and stitch-bonded fabrics.

Today, most factories use woven cotton cloths of the flannelette or swansdown type. Their surface fluff allows greater uptake and retention of impregnating solutions.

The nap is created by passing the cloth over a rotating drum fitted with hooked steel wire spikes that tease up the fibres. Weave constructions may be plain, twill, or duplex.

Non-woven fabrics are used only for lighter toe puffs because they cannot hold large amounts of impregnant. By contrast, needle-punched fabrics absorb significantly more resin, making them suitable for heavier toe puffs.

Solvent-Activated Impregnated Toe Puff Manufacturing

Solvent-activated toe puffs are impregnated using nitrocellulose or polystyrene resins. During nitrocellulose production, manufacturers pass the base fabric through a bath containing nitrocellulose dissolved in a water-miscible solvent such as acetone or alcohol.

The fabric then passes through a water bath that extracts the solvent, causing nitrocellulose to precipitate within the fabric. After drying, the discontinuous impregnation structure provides flexibility and allows the material to be rolled for transport.

In the shoe factory, operators soften nitrocellulose toe puffs using acetone blended with other solvents to control activation speed and tack development.

Polystyrene has become increasingly popular as an impregnating resin. Manufacturers follow similar production methods, although the solvent blend must include toluene to dissolve the resin effectively.

To prevent sticking to the last, manufacturers may impregnate the base fabric with a water-based polystyrene plasticiser dispersion. For improved adhesion, suppliers often pre-coat one side of the material with a solvent-activated adhesive.

Related Posts

Thermoplastic (Heat-Activated) Toe Puff Systems

In early development stages, manufacturers impregnated heat-activated puffs with PVA or polystyrene and bonded them using latex, rubber, or neoprene adhesives. Modern systems now use adhesive coatings based on PVA, polyacrylate, EVA, neoprene, polyurethane, or gutta-percha, combined with resins and plasticisers to achieve required bonding properties.

Metering of impregnant is critical. If impregnation is insufficient, the puff will not fuse fully, resulting in weak and moisture-sensitive reinforcement. Conversely, excessive impregnation produces a hard and brittle structure.

Process Control and Defect Risks in Impregnated Toe Puffs

Manufacturers commonly apply adhesive coatings using spreading techniques. The adhesive is thickened to a soft paste, and spreading machines typically apply around 100 g/m².

More recently, factories have adopted hot-melt adhesives, which are heated to 140–160°C and applied as a single uniform coating.

Fungicides may be introduced during impregnation to improve rot resistance. If the puff fails to fuse fully during wear, moisture penetration may promote mould growth.In addition, excess salt spew can occur if materials contain high salt content.

Pro Tip: Impregnation Control: Incorrect resin loading is one of the most common root causes of toe puff failure. Always validate impregnation levels using controlled peel strength and flex testing before bulk production approval.

Print-On Hot-Melt Resin Toe Puffs

Print-on thermoplastic toe puffs, widely used since the mid-1960s, represent a development of paint-on systems in which the solvent has been eliminated.

Three main types exist:

- Tru-line process, which uses a polyamide resin in rod form that is extruded, melted, and injected into a mould cavity adjacent to the flesh side of the leather.

- Transfer sheet method, where a thermoplastic polyamide resin film cast on release paper is transferred to the upper using a heated die.

- Direct mould injection systems, where a thermoplastic resin is injected into a mould shaped like the toe puff and automatically applied to the upper before setting.

Although mould-based systems improve uniformity and fusion, they require specialised machinery, which limits their suitability for short production runs.

Filmic Toe Puffs

Filmic toe puffs represent a further development of celluloid-based systems and use polymers such as ABS, Surlyn, TPU, and EVA. These materials rely on heat-activated adhesives during bonding.

Some filmic puffs compress to absorb upper creasing; however, careful handling remains essential.

If excessive heat softens the sheet, handling becomes difficult, while insufficient heat results in poor shaping during lasting.

Filmic toe puffs provide a smooth internal surface, improving comfort. However, brittleness and edge cracking may cause discomfort if material selection or processing is incorrect. Despite this, filmic systems remain the most promising modern toe puff technology.

Pro Tip: Filmic Puff Processing : Always validate press temperature and dwell time. Filmic toe puff failures are more often process-related than material-related.

Recommended Uses of Toe Puff Types (Thickness Guidelines)

Solvent-Activated Fabric-Based Toe Puffs

- Cellulose nitrate impregnated

- 0.7–0.9 mm: Women’s shoes

- 0.9–1.2 mm: Women’s heavy shoes, children’s and men’s light shoes

- 1.2–1.6 mm: Men’s and boys’ shoes

- 1.6–2.0 mm: Men’s heavy shoes, industrial boots, sports shoes

- Polystyrene impregnated

- 0.5–0.8 mm: Women’s shoes

- 0.8–1.0 mm: Women’s heavy shoes and children’s shoes

- 1.0–1.2 mm: Men’s and boys’ shoes

- 1.2–1.6 mm: Men’s heavy shoes and sports shoes

- 1.6 mm and above: Industrial boots

Liquid Toe Puffs

- Primarily used for children’s sandals

Thermoplastic Polystyrene-Impregnated Fabric Puffs

- 0.4–0.7 mm: Women’s and children’s shoes

- 0.7–1.0 mm: Women’s heavy shoes, boots, children’s and men’s light shoes

- 1.0–1.2 mm: Men’s and boys’ shoes

- 1.2–1.5 mm: Men’s heavy shoes, industrial boots, sports shoes

Print-On Toe Puffs

- 0.5–1.0 mm: Women’s shoes

- 1.0–1.5 mm: Men’s and boys’ shoes

Filmic Toe Puffs

- 0.5–0.7 mm: Women’s light shoes and children’s shoes

- 0.8–1.1 mm: Men’s and boys’ light shoes

Pro Tip: Material Selection Mistake : Selecting toe puff thickness based only on shoe category often leads to failures. Always consider upper material softness, vamp design, and lasting tension together.

Summary

Toe puff and stiffeners play a critical role in preserving last shape and shoe appearance. Historically, footwear used a wide range of materials. However, modern production relies mainly on impregnated fabrics, print-on hot-melt systems, and filmic thermoplastics.

Although solvent-activated systems offer a broad performance range, manufacturers increasingly replace them with cleaner and more controllable heat-activated alternatives. Filmic toe puffs represent the most advanced technology, while print-on systems require investment in specialized equipment.

Correct material selection, impregnation control, and process validation remain essential for long-term performance.

Following are some of the Major Suppliers of Toe Puff and Stiffener Materials Globally.

1. Milspeed – UK-based Global Shoe Component Specialist

Milspeed is a leading global manufacturer of tri-laminate shoe reinforcement materials, including box toe puffs, counters, stiffeners, and adhesive systems used by world-class footwear brands. The company combines innovation, sustainability, and technical expertise to deliver high-performance components that maintain shoe shape and durability throughout wear. In addition, Milspeed supports both mainstream and premium footwear manufacturers through strong R&D capabilities and a global distribution network. With SATRA membership and a focus on environmentally responsible materials, the company continues to strengthen its position as a trusted supplier of footwear reinforcement solutions.

🔗 Source: https://milspeed.com/company/

2. Texon (Coats Footwear) – Structural Materials & Toe Puff Leader

With over 75 years of footwear industry experience, Texon, a brand under Coats Footwear, supplies high-performance structural materials such as extruded toe puffs, thermoplastic stiffeners, and heel counters. The product portfolio includes sustainable reinforcement solutions with high recycled content and excellent shape-retention properties. Furthermore, Texon operates manufacturing and technical support centres across Asia and Europe, ensuring close collaboration with major footwear producers. Its engineered materials serve fashion, athletic, and technical footwear segments worldwide.

🔗 Source: https://www.texon.com/product-type/box-toe-puffs/

3. QUINORGAN – European Manufacturer of Toe Puffs & Reinforcements

Quinorgan is a long-established European supplier with more than 90 years of experience in footwear materials, specialising in toe puffs, stiffeners, reinforcements, and adhesives. Its thermoadhesive toe puff systems offer excellent mouldability, controlled stiffness, and long-term shape retention. As a result, Quinorgan materials suit casual, formal, and performance footwear applications. The company places strong emphasis on quality consistency, regulatory compliance, and adaptability to evolving sustainability requirements.

🔗 Source: https://quinorgan.com/en/footwear/

4. Keck Chimie (Distributor for ICF Group SpA) – Specialist in Reinforcement Fabrics

Keck Chimie acts as the exclusive French distributor for ICF Group SpA’s advanced toe puff and stiffener fabrics. Its portfolio includes thermoplastic, composite, and flexible reinforcement materials supplied with adhesive coatings for reliable bonding. Moreover, these materials support both traditional craftsmanship and high-performance footwear manufacturing. With variable rigidity options and biodegradable solutions, Keck Chimie serves leather, synthetic, and technical upper applications across global footwear markets.

🔗 Source: https://www.keck-chimie.fr/en/our-products/footwear/toe-puffs_stiffeners/

5. WINIW International Co., Ltd – China-Based Structural Material Supplier

WINIW International is a leading Chinese supplier of shoe materials, including toe puffs, counter sheets, non-woven stiffeners, and thermoplastic reinforcement fabrics. The company supports global footwear and leather goods manufacturers with a wide range of thickness and stiffness options. In addition, WINIW combines competitive pricing with consistent quality for mass-production environments. Its materials are widely used in safety footwear, boots, casual shoes, and fashion footwear.

🔗 Source: https://www.shoe-materials.com/product-category/toe-puff-counter/

6. HIGHGROWTH Trade Pvt Ltd – Global Importer for Asian Footwear Components

Based in India, Highgrowth Trade supplies globally sourced toe puffs, counters, and heat-activated reinforcement sheets to footwear manufacturers. With nearly two decades of industry experience, the company focuses on delivering reliable structural components from established global producers. Consequently, manufacturers benefit from improved comfort, shape retention, and durability in finished footwear. Highgrowth Trade is recognised for supply reliability, competitive pricing, and strong technical support.

🔗 Source: https://sites.google.com/view/highgrowth-trade/blogs/footwear-raw-material-supplier-in-india

7. RIMCORE – Polymer-Blend Footwear Toe Puff & Stiffener Producer

RIMCORE specialises in polymer-blend structural reinforcements, including thermoplastic toe puffs and stiffeners engineered for dynamic footwear performance. Its FLEXORA and FLEXOMELT product ranges focus on elasticity, rebound behaviour, and compatibility with modern lasting processes. As a result, RIMCORE materials support both traditional constructions and innovative footwear designs. The company serves everyday, comfort, and performance footwear segments.

🔗 Source: https://rimcore.in/footwear/toe_puffs.php

8. ICF Group SpA (via Keck Chimie) – Italian Toe Puff Fabric Innovator

ICF Group SpA develops extruded thermoplastic and composite fabrics used as toe puffs, semi-rigid stiffeners, and reinforcement materials. Its Flexan, Janus, and Gemini product families offer controlled rigidity, thermal formability, and sustainable material options. Backed by Italian manufacturing expertise, ICF Group supports premium and technical footwear brands worldwide. The company remains a key innovator in reinforcement fabric technology.

🔗 Source: https://www.keck-chimie.fr/en/our-products/footwear/toe-puffs_stiffeners/

9. Dongguan L&N Shoe Material Co., Ltd – Thermoplastic Toe Puff Supplier

Dongguan L&N supplies thermoplastic toe puff and counter stiffener materials with adjustable stiffness, heat-activation properties, and customised thickness options. The company serves both small and large footwear manufacturers through flexible order quantities and export-oriented supply chains. Its products support diverse upper materials and lasting techniques while maintaining reliable bonding strength.

🔗 Source: https://www.gotosuppliers.com/supplier/dglinuo/profile.html

10. Guangzhou Ruifeng New Material Co., Ltd – Performance Reinforcement Producer

Guangzhou Ruifeng manufactures toe puff and stiffener materials designed for durability, flexibility, and consistent bonding performance. The company supplies thermoplastic and hot-melt reinforcement systems for safety, casual, and performance footwear. By focusing on eco-friendly formulations and process stability, Ruifeng supports large-scale footwear production with repeatable results.

🔗 Source: https://www.company-listing.org/ruifeng_new_material_co_ltd.html