The Ultimate Guide to Adhesives in Footwear: Mastering Sole Bonding for Quality and Durability

Reading Time : 6 minutes

Introduction

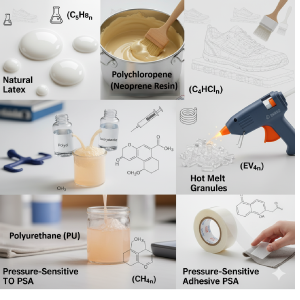

In the fast-paced world of footwear manufacturing, where consumer demands for quality, comfort, and longevity are at an all-time high, the choice of adhesives plays a pivotal role. Imagine investing in premium materials only for your shoes to fall apart due to poor sole adhesion – a nightmare for both manufacturers and customers. The footwear industry relies heavily on various adhesives for different operations, but none is more critical than bonding the sole to the upper. This process ensures the shoe’s structural integrity, preventing common failures like delamination or separation.

Unfortunately, many manufacturers overlook the technical nuances, leading to bonding issues stemming from incorrect adhesive selection or improper application methods. This comprehensive guide dives deep into the mechanisms of adhesive bonding in footwear, fault analysis, prevention strategies, and quality assurance practices. Whether you’re a footwear industry professional, a budding manufacturer, or simply curious about what keeps your shoes together, you’ll gain valuable insights into achieving superior sole adhesion. By understanding these principles, you can enhance product quality, reduce returns, and meet the growing expectations of eco-conscious and durability-focused consumers.

Understanding the Mechanisms of Adhesive Bonding in Footwear

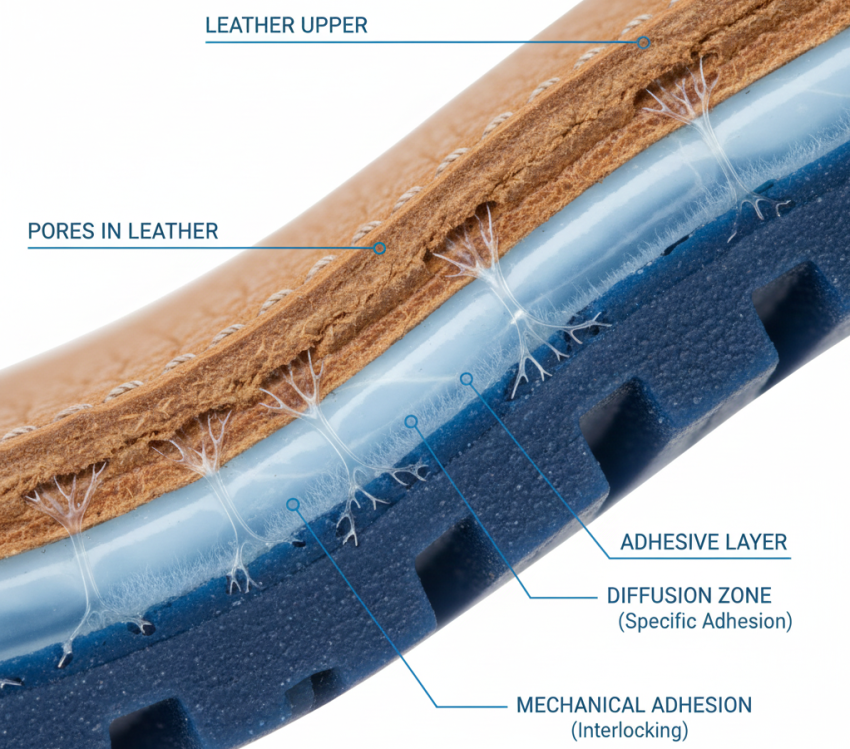

Adhesive bonding in footwear isn’t just about sticking two parts together; it’s a science that combines physics, chemistry, and material engineering. There are two primary mechanisms: mechanical adhesion and specific adhesion. Mastering these is essential for preventing bonding failures and ensuring long-lasting footwear.

Mechanical Adhesion: The Foundation of Strong Bonds

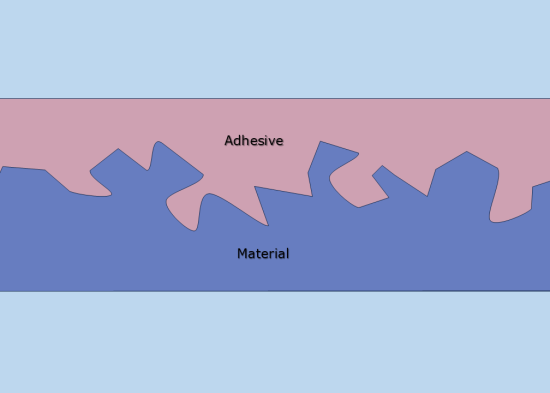

Mechanical adhesion is the most common mechanism and works effectively across various materials. It occurs when the adhesive, in its liquid form, flows into the microscopic pores, rough surfaces, or fibrous structures of the materials being bonded. Once dried, the adhesive “keys” into these irregularities, much like interlocking puzzle pieces.

The strength of this bond depends on several factors:

- Material Strength: The inherent durability of the upper and sole materials.

- Pore Characteristics: Deeper, undercut pores create stronger bonds than shallow ones. Fibrous surfaces allow the adhesive to surround fibers, enhancing grip.

For instance, in footwear, roughing or scouring the surfaces increases pore depth, improving mechanical adhesion. However, over-roughing can weaken the material, so precision is key. This mechanism is vital for materials like leather, rubber, or PU-coated fabrics, where visible roughness aids in creating a robust interlock.

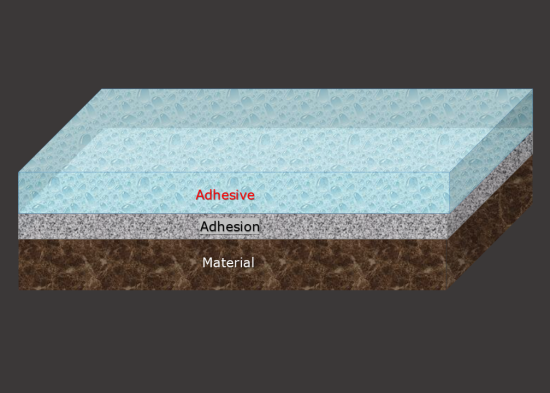

Specific Adhesion: Molecular-Level Bonding

On a finer scale, specific adhesion involves molecular interactions where adhesive molecules diffuse into the material’s surface, intertwining with its molecules. For this to happen, the attractive forces between the adhesive and material must match or exceed the adhesive’s internal cohesion.

Key enablers include:

- Solvents and Heat: Solvents in adhesives swell or dissolve the surface, promoting diffusion. Heat, used in hot-melt cements, allows films to coalesce.

- Chemical Bonding: Strong chemical links form when specific structures are present. Primers, like halogenating agents for thermoplastic rubber before applying PU cement, make surfaces reactive.

This mechanism is crucial for challenging materials like nylon, polyester, or EVA, where primers deposit compatible films or modify surfaces chemically for better compatibility.

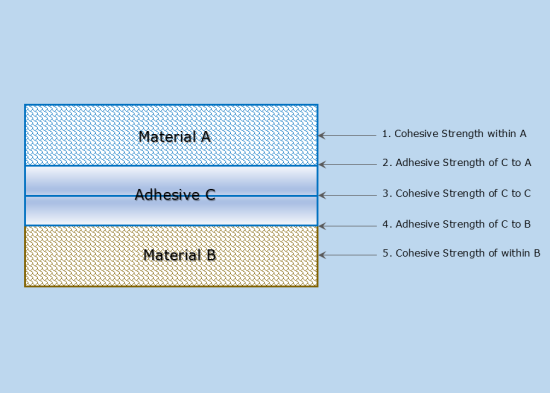

The Five Links of Adhesion: Ensuring Bond Strength

A strong adhesive bond in footwear can be broken down into five critical “links,” each contributing to overall strength. The bond is only as strong as its weakest link, making proper procedures non-negotiable, especially in sole bonding.

- Cohesive Strength Within Material A (Link 1): Remove weak layers, such as the grain from leather or PU coating from fabrics, through roughing.

- Adhesive Strength of Cement to Material A (Link 2): Depends on surface preparation (roughing, solvent wiping, priming), adhesive selection, viscosity, distribution, and drying time.

- Cohesive Strength Within the Cement (Link 3): Achieved through proper reactivation temperature, bonding pressure, pressure distribution, and dwell time (9-15 seconds for soles).

- Adhesive Strength of Cement to Material B (Link 4): Mirrors Link 2, emphasizing compatibility and application.

- Cohesive Strength Within Material B (Link 5): Similar to Link 1, focusing on sole material preparation

By addressing these links, manufacturers can prevent common sole bonding problems like weak adhesion due to contamination, insufficient drying, or uneven pressure.

Common Sole Bonding Problems and Prevention Strategies

Sole adhesion failures are a major pain point in the footwear industry, often resulting from overlooked technical details. Here’s how to analyze and prevent them:

- Surface Contamination: Grease, plasticizers, or mold-release agents weaken bonds.

Prevention: Use solvent wiping to clean and soften surfaces. - Improper Priming: For materials like rubber or EVA, inadequate priming leads to poor specific adhesion.

- Adhesive Mismatch: Choosing the wrong adhesive for materials causes failures.

Tip: Select based on compatibility, viscosity (not too high to block pores), and surface tension for better wetting. - Drying and Reactivation Issues: Insufficient drying retains solvents, weakening bonds. Ensure full solvent evaporation with adequate airflow and time.

- Pressure and Dwell Errors: Uneven pressure or short dwell times prevent proper conformation. Adjust pressure for material softness and use supports for curved areas like toes.

Regular fault analysis, such as checking for over-roughing or poor distribution, can preempt these issues, leading to footwear that withstands daily wear.

Sole Adhesion Monitoring and Quality Assurance Best Practices

To maintain consistent quality, continuous monitoring of sole adhesion is non-negotiable. Implement a robust system with these steps:

- Priming Protocols: Add fluorescent chemicals to primers for UV checks. Use fresh mixtures daily and store in light-proof containers.

- Upper Preparation: Ensure flat bottoms with at least 8-12mm lasting margins. Tailor surface prep to materials.

- Hardener Mixing: Follow supplier ratios using precise tools.

- Drying and Conveyor Setup: Adjust speeds for complete drying, varying with weather.

- Reactivation and Pressure: Maintain recommended surface temperatures provided by supplier and technical team; calibrate machines regularly. Use carbon paper tests twice daily.

- Post-Press Cooling: Employ chillers for immediate de-lasting.

- Testing: Conduct green tests on Satra sole adhesion testers at least twice a day.

These practices minimize variability, ensuring every pair meets high standards and reduces customer complaints.

Conclusion

Mastering adhesives in the footwear industry, particularly for sole-to-upper bonding, is the key to delivering products that combine durability, comfort, and quality. By understanding mechanical and specific adhesion mechanisms, optimizing the five links of adhesion, preventing common faults, and implementing rigorous quality assurance, manufacturers can overcome the biggest challenges in sole adhesion. This not only boosts consumer satisfaction but also enhances brand reputation in a competitive market.

Investing in technical knowledge and proper procedures pays off in longevity and reduced waste. As the industry evolves with sustainable materials and advanced adhesives, staying informed will keep you ahead. Remember, the right adhesive choice isn’t just about sticking – it’s about creating footwear that lasts.