The Ultimate Guide to Hardness Gauges for Footwear: Shore and Asker Durometers Explained

Reading Time: 5-6 minutes

What Are Hardness Gauges?

Durometers, commonly called hardness gauges, are simple tools that measure how much a material resists dents. For example, they help designers choose soft foams for comfort or firm rubber for long-lasting soles. Using Shore and Asker systems, these devices make sure shoes feel great and hold up over time. In this guide, we’ll explain what they are, why scales like A, C, and D exist, and how to use SATRA standards for accurate results.

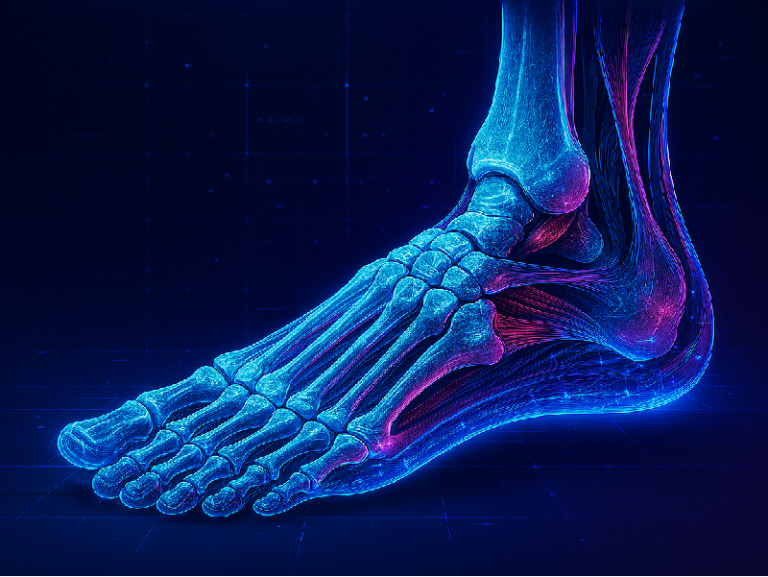

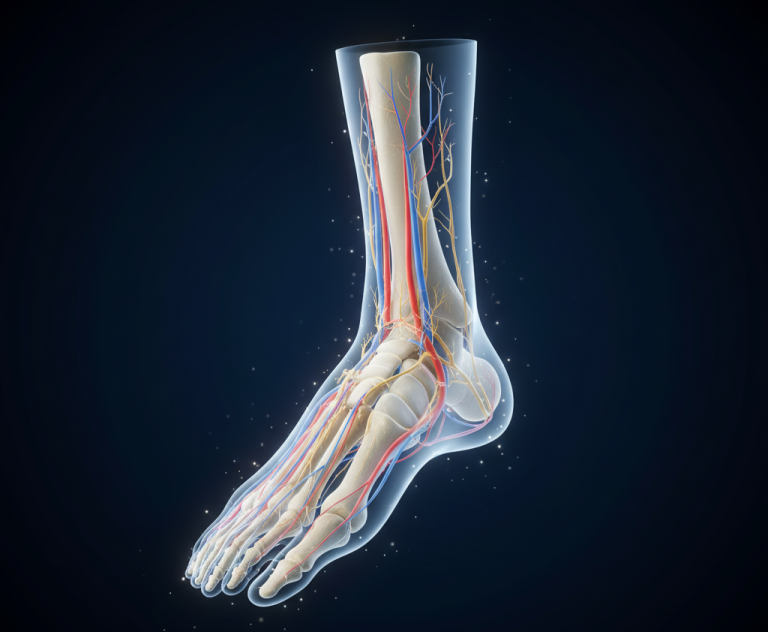

What Is Hardness and Why Does It Matter in Footwear?

Hardness shows how well a material fights dents. In shoes, it controls three key areas:

- Cushioning – Lower numbers soak up shock

- Durability – Higher ratings resist wear

- Energy return – Mid-range values give better push-off

Skip proper testing, and midsoles collapse fast, outsoles slip, or inserts cause blisters. On the other hand, studies show runners love dual-layer midsoles—like 40 Shore C in the heel and 60 in the forefoot—for up to 30% more comfort and speed.

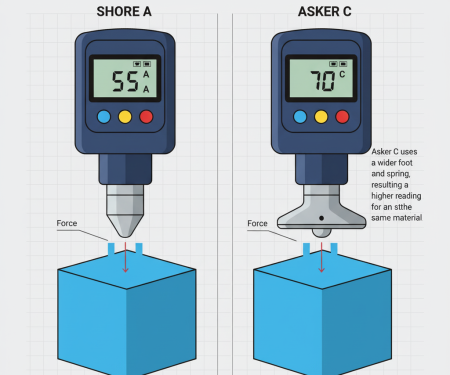

Shore and Asker: What’s the Difference?

Shore and Asker are the two main durometer systems. First, Shore started in the 1920s by Albert F. Shore. Later, Asker emerged in Japan after World War II. Both press a tip into the material, but they differ in design:

| Feature | Shore System | Asker System |

|---|---|---|

| Origin | USA (ASTM D2240, ISO 868) | Japan (JIS K 6253) |

| Probe Shape | Conical or round | Finer, more rounded |

| Spring Force | Higher (A: 822g) | Lower, more gentle |

| Best For | Rubbers, plastics | Soft gels, thin foams |

Why different names? Shore became the global standard. However, Asker grew in Asia because factories needed extra care with light foams. Important: A Shore A 50 does not equal Asker C 50.

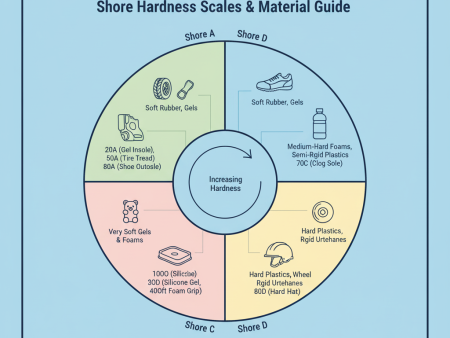

Why Do We Need Scales Like A, C, D, OO?

Not all materials are the same, so we use different scales. Each one has a unique tip and push strength:

- Shore A: Blunt cone → Rubber outsoles (55–70)

- Shore C: Rounded tip → EVA midsoles (35–55)

- Shore D: Sharp cone → Hard heel counters (65–85)

- Shore OO: Big ball → Soft gels (20–40)

- Asker C/F: Extra gentle for thin or super-soft parts

Why so many? Using the wrong scale gives bad data. For instance, Shore A on gel reads zero every time. On the other hand, Shore D crushes foam. Match the scale, and you get true results.

How to Use Hardness Gauges in Footwear (With SATRA Links)

| Component | Recommended Gauge | Typical Range | SATRA Reference |

|---|---|---|---|

| Outsoles (Rubber/TPU) | Shore A | 55–70 | SATRA TM 205: Rubber Abrasion |

| Midsoles (EVA/PU) | Shore C / Asker C | 35–55 | SATRA TM 159: Compression Set |

| Heel Counters | Shore D | 65–85 | SATRA TM 411: Stiffness |

| Gel Inserts | Shore OO / Asker F | 15–35 | SATRA TM 219: Energy Absorption |

For example, SATRA TM 205 shows 60 Shore A rubber wears less than 150mm³, while 50A loses over 250mm³. Source: SATRA Bulletin.

Recommended Durometer Devices: Top 3 Worldwide Options

To put theory into practice, here are three top-rated hardness gauges (durometers) widely available globally. These are selected for their reliability, compatibility with Shore and Asker scales, and use in footwear testing labs. Prices vary by region; check vendors like Amazon, Grainger, or direct sites.

H-B Instruments

PCE-DDM 4 Digital Durometer

Features: Dual Shore A/D scales, digital LCD for precise ±1 HA readings, USB data export for batch analysis, battery-powered with auto-off, ideal for rubber outsoles and plastic inserts. Compact (180g) for field use.

PCE Instruments

Rex Gauge Model 1600 Shore A Durometer

Features: Analog dial with peak pointer, NIST-traceable calibration, 0-100 HA range, rugged aluminum body, constant load (822g) for accurate rubber/TPU testing; includes test stand option for consistency.

Rex Gauge

H-B DURAC Shore A Durometer

Features: Analog, 0-100 HA scale with color-coded zones, lightweight (150g), carrying case included; excels in soft-to-medium foams and gels for midsoles/insoles. Affordable entry-level for small brands.

H-B Instruments

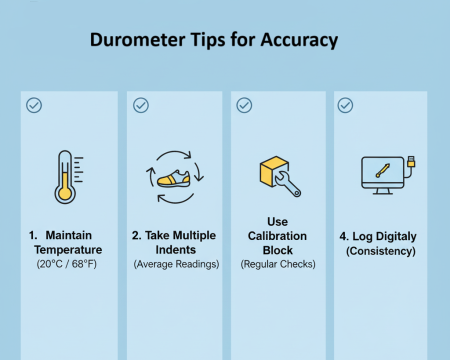

Pro Tips for Accurate Hardness Testing

- Match the gauge to the material – Never use Shore D on foam

- Keep conditions steady – 23°C, 50% humidity

- Take 5+ readings – Average them

- Calibrate every year

- Use digital logs to track trends

Final Thoughts

Shore and Asker durometers are more than tools—they help you speak the language of shoe performance. Now that you know why A, C, D scales exist, how Shore and Asker differ, and when to use SATRA standards, you can build better shoes. Start with a simple PCE-DDM 4—one accurate test can shape your next hit product.