Footwear Manufacturing Insights: Lining Fold Lines & Seamless Heel Counters

Reading Time : 3 Minutes

In footwear manufacturing, visual cleanliness is just as important as structural strength. Central seams, if not carefully planned, often show through thin uppers and affect the final appearance of the shoe. This article explains two proven pattern techniques used to avoid visible seams: fold lines in whole-cut linings and back parts without a central seam. Both methods improve aesthetics while maintaining durability and fit.

Fold Line in Whole-Cut Linings

In well-sprung leather vamp linings, it has traditionally been common practice to join the lining at the center using a closed seam. While this helps emphasize the spring of the last, central seams tend to show through on the outer upper, especially when thin upper leathers are used.

A more refined solution is to divide the vamp lining on one side instead of the center.

Key Pattern Principles of fold line in whole-cut linings

- The lining is split on one side and well skived

- The two parts are bonded one over the other, not stitched centrally

- This creates a firm joint without visible seam lines on the outside

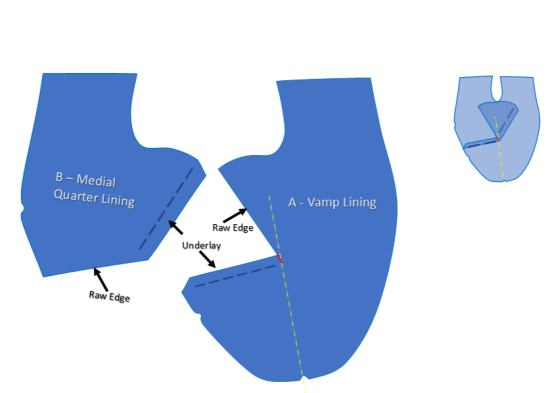

Understanding the Diagram

- Figure A shows the whole vamp lining with No joint in the Lateral side

- Figure B shows the quarter Lining with allowance for the fold line

By shifting the joint away from the center, the lining follows the spring of the last naturally while keeping the upper visually clean.

Manufacturing Benefits

- Maintains lining strength and shape

- No seam show-through on thin uppers

- Cleaner appearance on whole-cut or minimal designs

Seamless Heel Counter

Closing the back part without a central row of stitching requires skill and accurate pattern control, but the result is a superior heel appearance.

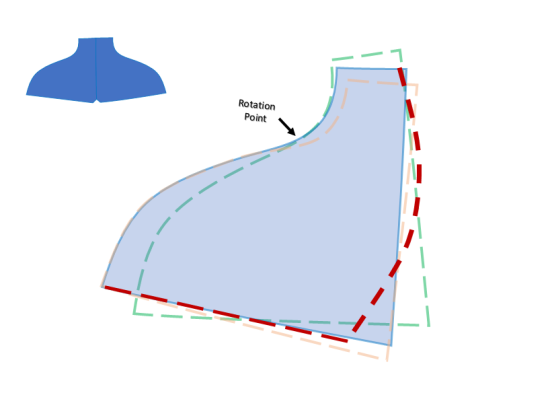

Instead of relying on a straight central seam, the pattern must follow the true heel curvature of the last.

Construction Method for seamless heel counter

- From point Rotation Point, the heel curve of the last is carefully followed

- During stitching from Green to Orange Line , the lower part of the counter is gradually caught up

- This allows the back part to match the seat curvature of the last

The illustrated sketch shows how such counters are designed in one piece, eliminating the need for a central seam while still achieving correct heel shape.

Advantages

- Premium appearance suitable for high-quality footwear

- Smooth heel surface without stitch line visibility

- Less Quality issues due to Back Closed Seam (Off Centre / Crooked / Broken Stitch)

Conclusion

Both techniques highlight how minor pattern adjustments produce major quality improvements. Correct notch placement in backseams ensures clean heel finishing, while controlled spring adjustment in boot vamps improves fit and manufacturing ease. For footwear professionals, mastering these small details leads to consistent quality, better comfort, and fewer production issues.