Footwear Manufacturing Insights – Reinforcement Techniques for Durable Shoe Construction

Reading Time : 5 Minutes

In modern footwear pattern engineering, reinforcement represents a fundamental engineering requirement rather than a secondary supporting operation. During shoe production, upper materials experience significant mechanical forces, including stretching during lasting, compression during bottoming, and repeated flexing during wear. If manufacturers fail to manage these forces effectively, material failure can occur either during production or after limited consumer use.

For this reason, engineers must plan reinforcement carefully and apply it systematically. When reinforcement is designed correctly, it improves structural stability, enhances shape retention, and delivers long-term durability without negatively affecting comfort or visual appearance. In contrast, poorly designed or incorrectly positioned reinforcement often leads to wrinkling, cracking, seam failure, or delamination.

Purpose and Functional Role of Reinforcement in Footwear

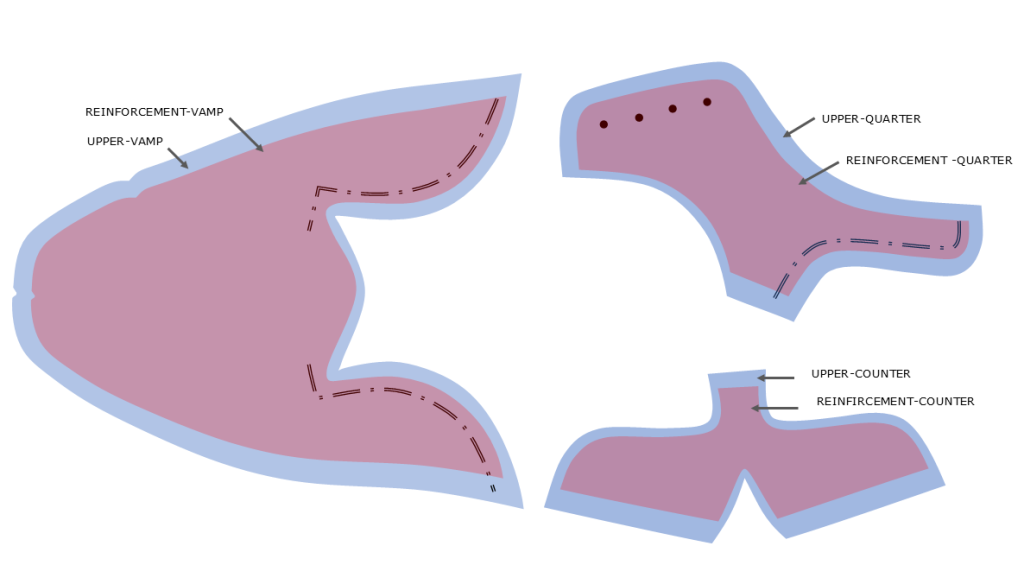

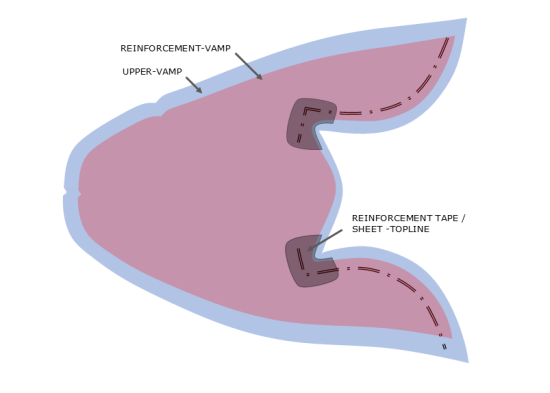

From a functional perspective, reinforcement is introduced into footwear construction to control how upper materials behave under stress. Most upper materials stretch during lasting and later experience dynamic movement during wear. Therefore, reinforcement supports areas where the natural strength of the material is insufficient.

By redistributing stress over a wider area, reinforcement reduces localized overloading and prevents premature tearing or distortion. In addition, it supports consistent shape retention in high-stress zones such as lacing areas, seams, perforations, and attachment points.

Designers can also use lighter, softer, or more flexible materials without compromising durability. As a result, reinforcement remains a key enabler of modern footwear design.

When Reinforcement Becomes Necessary

This requirement typically arises when upper materials do not provide sufficient tensile strength, tear resistance, or dimensional stability.

Requirement of Reinforcement is :

- In many uppers, materials exhibit high stretch or low tear strength

- During lasting, strong mechanical forces are applied

- At stitching zones, high stitch density creates stress concentration

- In decorative designs, perforations weaken the upper material

- Under load, straps, buckles, or eyelets transmit concentrated forces

Consequently, even minimal or lightweight footwear designs rely on carefully positioned reinforcement components.

Reinforcement as a Design and Engineering Responsibility

Designers and pattern engineers must address reinforcement during the early design and pattern engineering stage. They should never treat reinforcement as a corrective measure after defects appear during production.

When teams add reinforcement as an emergency solution, secondary problems such as excessive stiffness, discomfort, or bonding failure often occur. Therefore, engineers must design reinforcement together with pattern geometry, stitch layout, and material selection.

Pro Tip: Reinforcement zones should be clearly marked on pattern components and controlled through BOM and process sheets to ensure consistency from sampling to bulk production.

Primary Reinforcement Strategies Used in Footwear

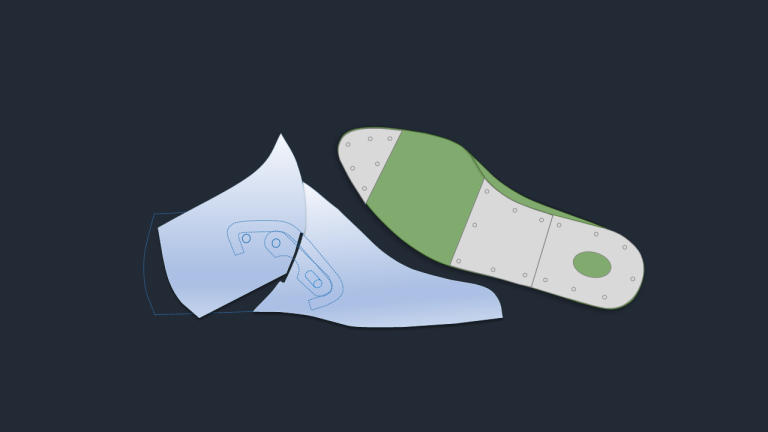

Common uses of two principal reinforcement strategies in footwear construction.

1. Overall Reinforcement

Overall reinforcement involves applying a reinforcing layer across a large portion of the upper. Such approach is when the base material lacks sufficient structural stability.

While overall reinforcement improves shape control, excessive use may reduce flexibility and breathability. For this reason, engineers must carefully balance thickness and stiffness.

2. Local Reinforcement

Apply local reinforcement only in high-stress zones. This targeted approach preserves flexibility and comfort to deliver strength exactly where it is needed.

As a result, local reinforcement is preferred in most modern footwear designs due to better performance balance and material efficiency.

Pro Tip: Local reinforcement must extend beyond the visible stress area. If reinforcement ends exactly at a stress line, it becomes ineffective.

Common Reinforcement Materials Used in Footwear

Reinforcement materials include non-woven polyester or polyamide fabrics, polymer-coated materials, thermoplastic heat-activated sheets, and lightweight woven textiles. In many cases, manufacturers engineer reinforcements as composite structures to combine strength with flexibility.

Material compatibility is critical. When stiffness mismatch occurs between the upper and the reinforcement, wrinkling or cracking can develop during wear.

Methods of Applying Reinforcement

In production environments, manufacturers apply reinforcement using either heat activation or adhesive bonding. In heat-activated systems, bonding occurs during pressing under controlled temperature and pressure. In adhesive systems, surface preparation plays a decisive role in bonding quality.

In both cases, operators must avoid excess adhesive and uneven pressure to prevent stiffness and visible surface defects.

Surface Preparation and Bonding Quality

Bonding performance depends heavily on surface cleanliness, pressure uniformity, temperature control, and bonding time. When preparation is inadequate, partial delamination or reinforcement lifting often occurs during wear.

Reinforcement Placement and Wrinkling Control

Wrinkling typically occurs when reinforcement ends abruptly or crosses high-flex zones. To control this issue, engineers should taper reinforcement edges or scatter them gradually.

Pro Tip: Reinforcement edges should never be perpendicular to the main flex line of the shoe.

Posts to explore

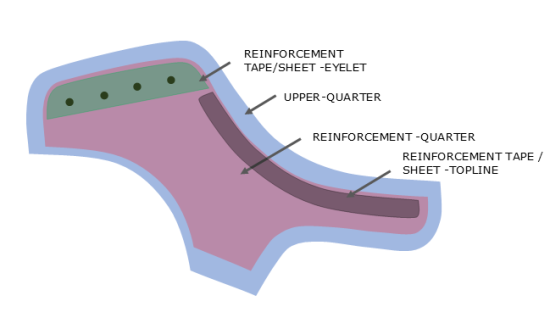

Eyelet, Strap, and Perforation Reinforcement

In Practical terms, eyelets require reinforcement extending at least 10 mm beyond the eyelet row. Straps and buckles require continuous reinforcement beneath the stitching area. Perforations must be fully backed, with reinforcement extending beyond the perforated boundary.

Correct and Incorrect Reinforcement Practices

Incorrect practices include narrow reinforcement under wide straps, gaps between reinforcement segments, and reinforcement ending exactly at stress points. In contrast, correct practices involve continuous coverage, adequate overlap, alignment with load direction, and smooth stress transition.

Typical Reinforcement Failures Observed in Production

Reinforcement failures are commonly caused by incorrect material selection, insufficient coverage, poor bonding, or excessive stiffness. These failures typically appear during lasting operations or early wear testing.

Testing and Test Methods for Reinforcement Materials (SATRA Standards)

To ensure consistent performance, manufacturers validate reinforcement backers, stiffeners, and reinforcement tapes using standardized SATRA test methods. These tests confirm that materials deliver adequate strength, controlled stretch, flexibility, and bonding durability under real footwear conditions.

Testing Requirements for Reinforcement Backers

Reinforcement backers support upper materials without restricting natural movement. For this reason, laboratories must evaluate both strength and flexibility characteristics.

Common SATRA Test Methods:

- Tensile Strength and Elongation – SATRA TM2

Used to measure breaking strength and elongation behavior. This ensures the backer can withstand lasting and wear stresses while maintaining controlled stretch. - Flex Resistance – SATRA TM55

Evaluates resistance to cracking or breakdown under repeated flexing. - Adhesion Strength – SATRA TM173

Measures bonding performance between the backer and the upper material.

Pro Tip: Tensile strength and elongation results must be reviewed together. A backer with high strength but very low elongation may cause wrinkling, while excessive elongation may fail to control stretch.

Testing Requirements for Stiffeners

Stiffeners are evaluated primarily for shape control and thermal behavior. For this reason, mechanical strength remains relevant.

Common SATRA Test Methods:

- Stiffness Measurement – SATRA TM46

- Heat Activation and Softening – SATRA TM92

- Shape Retention After Forming – SATRA TM83

When flexible thermoplastic stiffeners are used. As a result, teams should also review tensile and elongation behavior to reduce cracking risk.

Testing Requirements for Reinforcement Tapes

Reinforcement tapes act as critical load-bearing components within seams and stitched zones. Their tensile strength and elongation behavior directly influence seam durability.

Common SATRA Test Methods:

- Tensile Strength and Elongation – SATRA TM2

Confirms that reinforcement tapes can withstand stitch-transmitted loads without tearing or excessive stretch. - Peel Adhesion Strength – SATRA TM425

Evaluates tape bonding durability. - Seam Strength – SATRA TM180

Pro Tip: Tapes must reinforce the seam without becoming either the weakest or the most rigid component.

Conclusion

Reinforcement plays a critical structural role in footwear manufacturing. When engineers design, position, and apply reinforcement correctly—and validate it through appropriate SATRA testing—it significantly improves durability, shape stability, and overall product quality. By integrating reinforcement engineering with standardized test requirements, manufacturers reduce defects, ensure consistent performance, and meet global brand expectations with confidence.