Footwear Manufacturing Insights – Determining the Vamp Point & Economical Counter Lining Cutting

In footwear pattern engineering, precise control of vamp length and material efficiency plays a critical role in achieving both fit accuracy and cost-effective production. Traditional pattern-modelling techniques provide simple yet reliable methods to define key reference points and reduce material waste.

This article explains two essential construction principles extracted from classical pattern manuals:

- Designing counter linings for economical cutting with zero waste

- Determining the vamp point using the last form

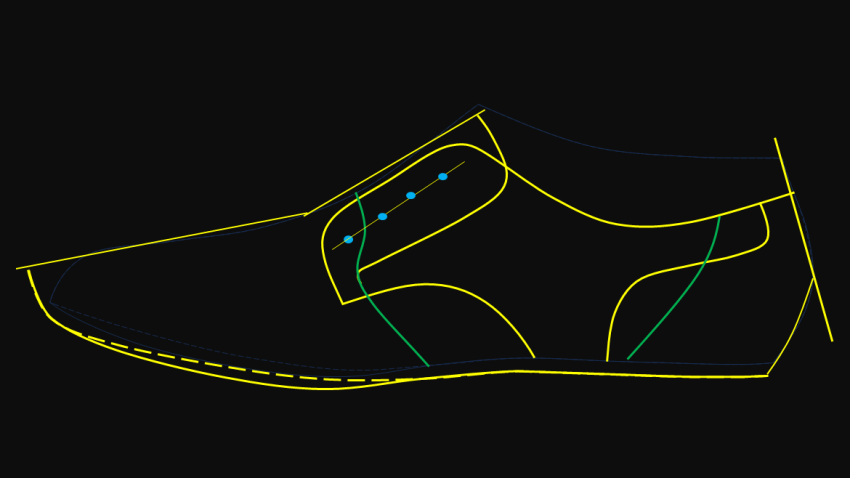

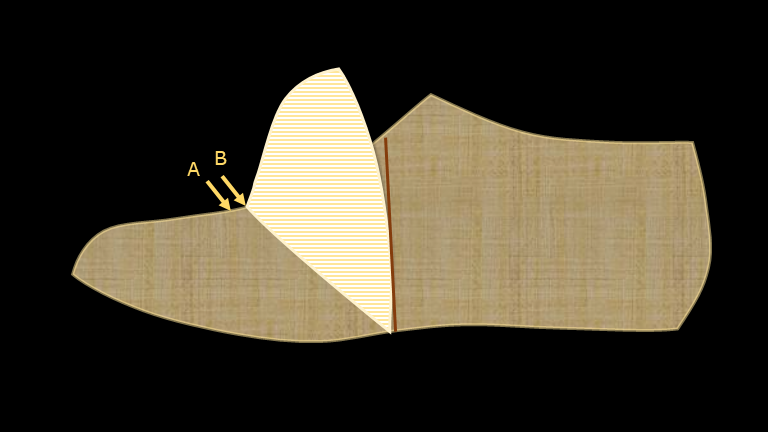

Determining the Vamp Point

The vamp point defines the forward limit of the vamp and has a direct influence on fit, flex position, and upper balance. Incorrect positioning can result in discomfort, poor crease behaviour, or lasting difficulties.

Relationship Between Vamp Point and Derby Point

In standard practice:

- The vamp length point (A) lies approximately 2.5 mm in front of the Derby point (B)

This small but critical offset ensures correct vamp coverage while maintaining flexibility at the instep.

Locating the Derby Point Using the Last

The Derby point is not guessed or measured arbitrarily. It is found using the last form itself:

- The front part of the last is folded backwards

- Folding continues until the toe of the last reaches the crest of the last

- The point at which this alignment occurs identifies the Derby point (B)

Once the Derby point is established, the vamp point (A) is positioned 2.5 mm forward, as illustrated.

Manufacturing Value

Correct determination of the vamp point:

- Ensures balanced vamp length

- Improves flex behaviour during wear

- Reduces fitting corrections during trials

- Creates consistency across size runs

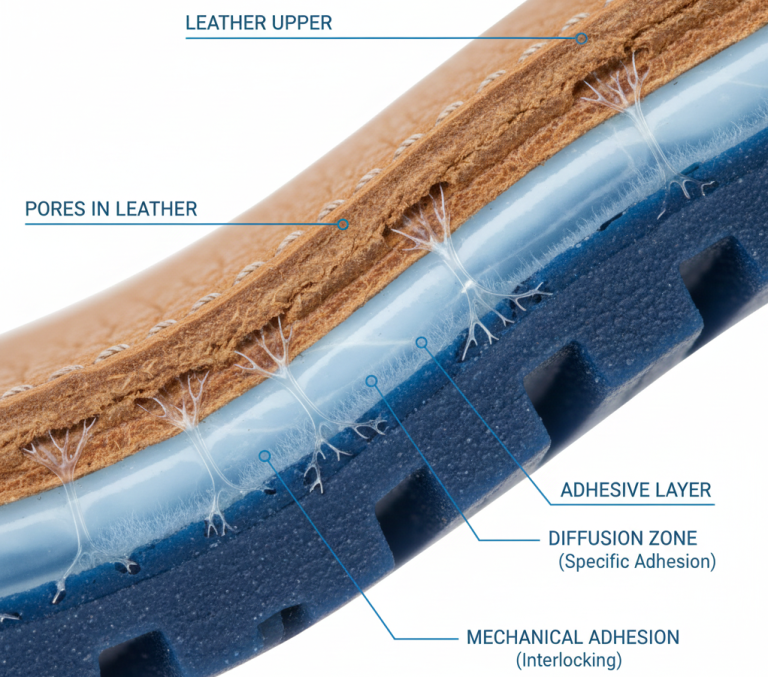

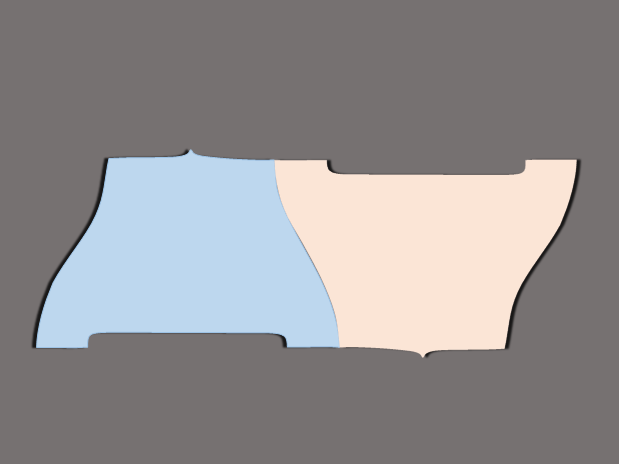

Cutting Out Counter Linings Economically

Counter linings contribute to heel stability and comfort, but inefficient pattern design can result in unnecessary material waste. Traditional cutting layouts address this issue through intelligent pattern geometry.

Principle of Economical Counter Lining Design

To cut counter linings efficiently:

- The counter lining patterns are designed as mirrored double parts

- Each cutting stroke produces one complete pair

- Patterns can be laid edge to edge continuously

This arrangement eliminates gaps between pieces and maximises material utilisation.

Material Efficiency Advantage

This cutting method provides several production benefits:

- No waste between adjacent parts

- Higher yield from lining material

- Faster cutting process

- Improved cost control in mass production

The illustrated layout shows how the patterns naturally interlock, allowing continuous cutting without leftover scrap.

Conclusion

By applying last-based methods to determine the vamp point and using efficient counter lining layouts, footwear manufacturers can achieve:

- Greater fit accuracy

- Improved upper balance

- Reduced material waste

- Lower production costs

These traditional pattern-engineering techniques remain highly relevant, offering practical solutions that combine precision with economy in modern footwear manufacturing.