Footwear Manufacturing Insights: Markings for Lining Stitching and Lasting Allowance in Veldtschoen Construction

Reading Time : 4 Minutes

Accurate marking and correct lasting allowance are critical details in footwear manufacturing that directly influence stitching accuracy, seam appearance, and overall shoe quality. In particular, lining stitching guidance and lasting allowance control in Veldtschoen construction require careful technical attention to avoid defects such as misaligned seams, broken tooling, or visible waviness along the welt.

This article presents classic yet highly relevant manufacturing instructions explaining practical methods for marking linings for stitching and controlling lasting allowance in Veldtschoen footwear. These principles remain valuable for designers, pattern engineers, and production technicians working in both traditional and modern factories.

Markings for the Stitching-In of Linings

Purpose of Stitching Markings

In lining operations, accurate stitch placement is essential to maintain consistent seam margins and a clean internal finish. Traditionally, press-knives used for twill and Mesh linings are equipped with prickers, which create small prick-marks in the material. These marks serve as a guide to facilitate accurate stitching of the leather lining.

Limitations of Prick-Mark Systems

Although prick-marks help guide the stitching operation, they present certain limitations:

- Prick-marks tend to close up easily, especially in soft lining materials

- Prickers often break off, because press-knives are frequently used to cut many layers at once

- Tool maintenance becomes more frequent, increasing downtime

Because of these drawbacks, alternative marking methods are often preferred in production environments.

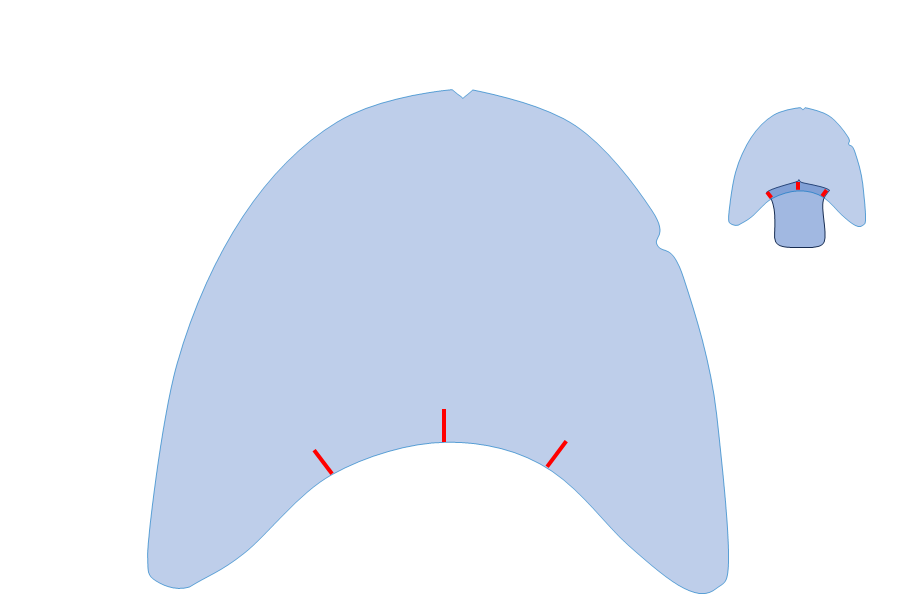

Using Incisions to Indicate Stitching Margin

A more reliable method consists of indicating the stitching margin by short incisions cut into the material. These incisions provide a clear and permanent visual reference point for the stitching operative.

Instead of prickers, the press-knives are fitted with small knives that create short slits in the lining material. These slits:

- Do not close up like prick-marks

- Are clearly visible during stitching

- Improve accuracy and consistency

- Reduce tool breakage issues

This method provides a dependable guide for stitching while improving operational efficiency.

Lasting Allowance for Veldtschoen Construction

Importance of Uniform Lasting Allowance

In Veldtschoen/Stitch down construction, the lasting margin is turned outward and later forms part of the visible structure of the shoe. For this reason, it is essential that the lasting allowance has equal substance and height at every point.

If the lasting allowance varies:

- The welt portion may later show wavy or uneven lines

- The visual quality of the shoe is reduced

- Stitch alignment becomes inconsistent and waviness

Preventing Waviness in the Welt

Waviness in the welt can be avoided by cutting the underlay portion of lasting allowance to a regular, controlled height. This ensures that material thickness and flexibility remain consistent throughout the perimeter of the shoe.

Maintaining a uniform lasting margin helps:

- Stabilize the turned-out upper

- Improve seam appearance

- Enhance overall shoe symmetry

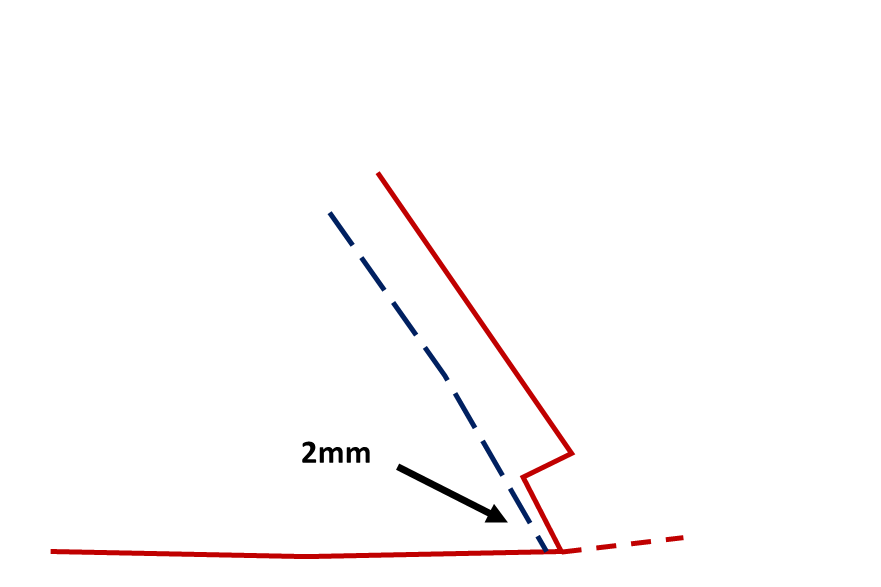

Correct Width of Lasting Allowance

A completely missing lasting allowance makes stitching difficult. However, reducing the allowance too much also creates problems.

In practice:

- A lasting allowance of only about 2 mm is insufficient

- Such a narrow margin cannot hold the parts securely in position

- The upper material tends to slip downward

- Both parts may lie edge to edge, causing the seam overlap to disappear

As a result, the seam lap no longer shows correctly, leading to structural and visual defects.

Practical Manufacturing Implications

These instructions highlight two important principles:

- Clear and durable marking methods improve stitching accuracy and efficiency

- Controlled lasting allowance is essential for quality Veldtschoen construction

Together, they help manufacturers achieve:

- Cleaner seams

- Improved durability

- Consistent visual appearance

- Reduced rework and rejection rates

Conclusion

Marking techniques for lining stitching and correct lasting allowance control are small but critical details in professional footwear manufacturing. Replacing traditional prick-marks with incision-based guides improves stitching reliability, while maintaining a uniform lasting allowance in Veldtschoen construction prevents waviness and seam defects.

For footwear professionals, mastering these foundational practices ensures higher quality output, better consistency, and long-term product performance—especially in classic construction methods where craftsmanship remains clearly visible.