Footwear Manufacturing Insights: Coordinating Lasts and Heel Height Impact on Foot Posture

Reading Time : 4 Minutes

In footwear manufacturing, last design plays a decisive role in determining fit, comfort, posture, and size consistency. Two fundamental but often under-explained concepts are coordinating lasts and the relationship between heel height and foot posture.

This article explains these principles in a structured and practical manner, helping footwear professionals, designers, and production teams understand how last engineering directly influences product performance and wearer comfort.

Understanding Coordinating Lasts in Footwear Manufacturing

What Are Coordinating Lasts?

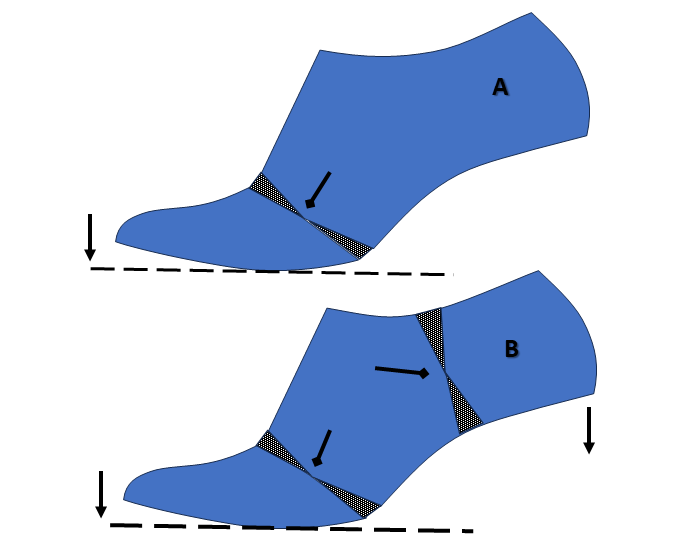

Coordinating lasts are designed so that toe spring and heel height remain constant across a full-size range or group/coordinate certain sizes, even though the shoe length and width increase or decrease. This consistency is essential to maintain uniform walking behavior and visual proportions across different shoe sizes.

To achieve this, the last is divided into two main sections:

- Forepart

- Back part (heel section)

Size adjustments are made by inserting or removing a wedge-shaped section at a defined dividing point.

- In one method, the adjustment affects only the toe area

- In another method, the adjustment affects only the heel area

This controlled modification ensures that changes in size do not disturb the functional posture of the foot.

How Coordinated Last Size Ranges Are Manufactured

Instead of producing every size individually, manufacturers create a series of sample lasts, which act as reference sizes.

A Coordinating System as follows

|

Groups |

Model / Master Size |

Size Ranges |

|---|---|---|

|

Group 2 |

US Size 8.5 |

US Size 8.0 – 9.0 |

|

Group 3 |

US Size 10.0 |

US Size 9.5 – 10.5 |

|

Group 4 |

US Size 11.5 |

US Size 11.0 – 12.0 |

While length and width follow standard grading rules, additional attention is required during upper pattern grading to accommodate the special geometry created by coordinated lasts.

Note: Above Grouping is just an illustration purpose.

Why Coordinating Lasts Are Important

Coordinating lasts help manufacturers to:

- Maintain consistent toe spring and heel height

- Reduce size-related issues during manufacturing

- Reduced tooling costs.

- Improve quality consistency in mass production

Heel Height and Foot Posture Relationship

How Heel Height Changes Foot Posture

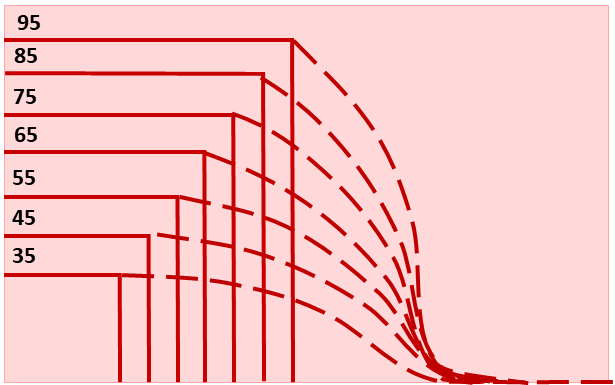

Heel height has a direct effect on the angle and posture of the foot. As heel height increases, the foot moves into a steeper position, changing how body weight is distributed.

Technical illustrations show that:

- Higher heels significantly increase pressure on the forefoot

- Low heel heights keep the foot closer to its natural posture

- Increasing heel height shifts body weight forward

Body Weight Distribution at Higher Heel Heights

As heel height increases:

- Body weight moves progressively toward the toes

- Pressure on the toe joints increases

- The heel supports less body weight

At extreme heel heights, almost the entire body weight rests on the toes, particularly on the toe joints. This condition places high stress on the forepart and requires precise last design and strong structural support.

Design Implications for Footwear Manufacturers

Understanding heel height and posture is critical for:

- Designing comfortable high-heel footwear

- Controlling pressure points

- Improving stability and balance

- Selecting appropriate materials and sole constructions

- Reducing fatigue and long-term discomfort for wearers

Linking Coordinating Lasts and Heel Height

These two concepts work together in footwear design:

- Coordinating lasts ensure posture consistency across sizes

- Heel height defines load distribution and comfort

- Proper last engineering balances both functional and aesthetic requirements

Ignoring either factor can lead to poor fit and discomfort

Conclusion

Coordinating lasts and heel height analysis are essential tools in professional footwear manufacturing. Coordinated lasts help maintain consistent fit and posture across size ranges, while an understanding of heel height explains how body weight and pressure distribution affect comfort and performance.