Footwear Edge Finishing & Binding Techniques

Edge finishing is a critical functional and aesthetic operation in footwear manufacturing. As a result, the way an edge or topline is finished directly influences wearing comfort, durability, and visual quality. In addition, improper edge treatment can lead to early failure, discomfort, and rejection during quality audits.

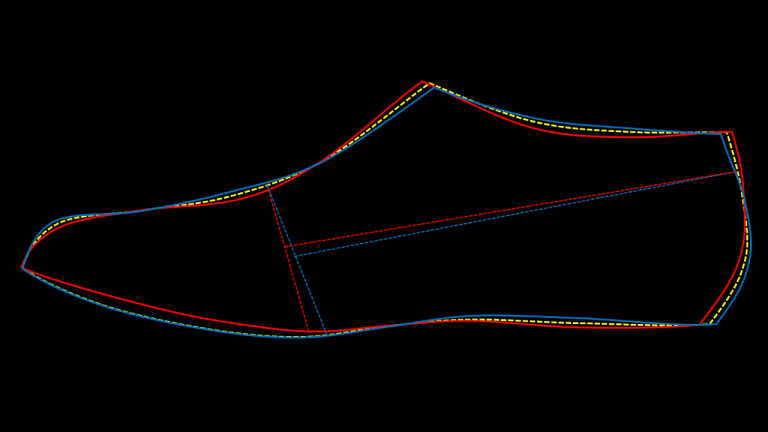

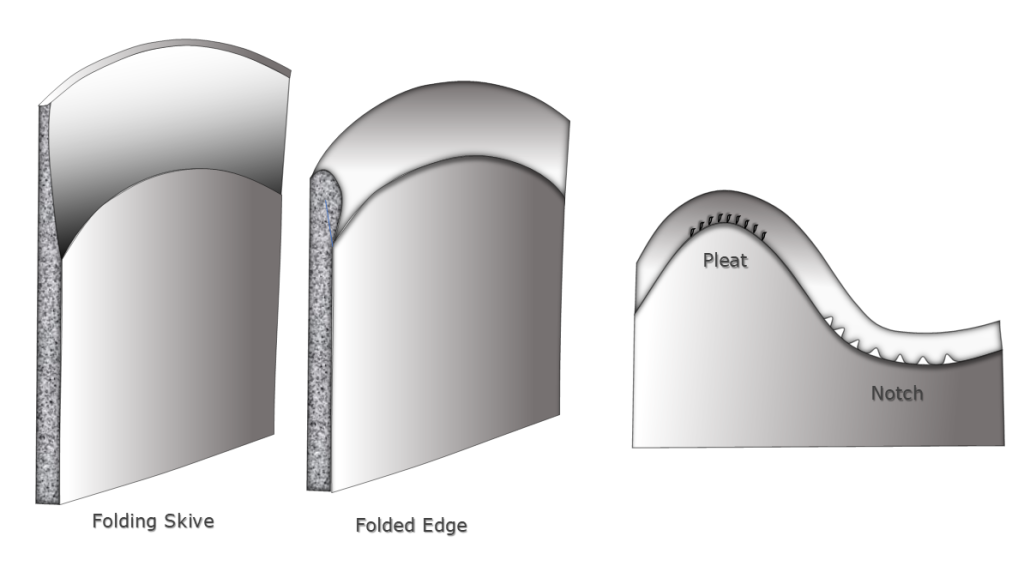

Folded Edge

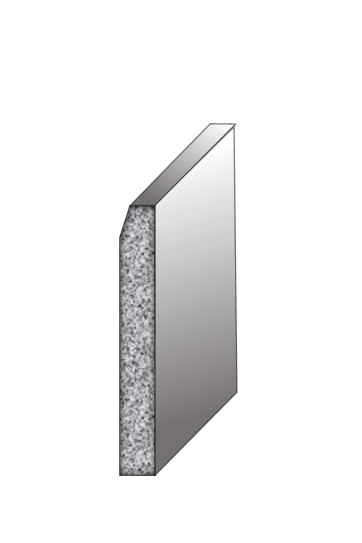

A folded edge is one of the most widely used edge-finishing techniques in footwear manufacturing. In this method, manufacturers skive the upper edge, apply adhesive, and turn the material over to fully enclose the raw cut edge. Consequently, the edge becomes both visually clean and functionally durable..

From a manufacturing perspective, folding demands strict control of skive depth and allowance. Inconsistent skiving often results in bulky edges, uneven folds, or shape distortion—especially around curves.

Typical process flow:

- Skiving the edge to uniform thickness

- Applying adhesive (latex, rubber, or thermoplastic)

- Turning the edge over by hand or machine

- Hammering or pressing the fold flat

- Pleating convex curves and notching concave curves

Typical allowances:

- Light calf or kid leather: approximately 3.5–4.0 mm

- Heavy grain leather or fabric: approximately 6.0–6.5 mm

Pro Tip: Folded Edge

Always verify skive consistency at the start of production because uneven skiving is the primary cause of fold cracking and edge roll-back.

Raw Edge

A raw edge is intentionally left unfolded and unbound. Therefore, this method relies entirely on precise cutting and controlled finishing. While it offers a minimalist appearance, it provides limited structural protection.

Although visually simple, raw edges require controlled finishing to avoid premature wear. In most factories, inking or sealing is applied to stabilise exposed fibres.

Key characteristics:

- No folding or binding

- Minimal material usage

- Reduced production time

Pro Tip: Raw Edge

Apply edge inking immediately after trimming, because untreated raw edges absorb moisture rapidly and deteriorate faster.

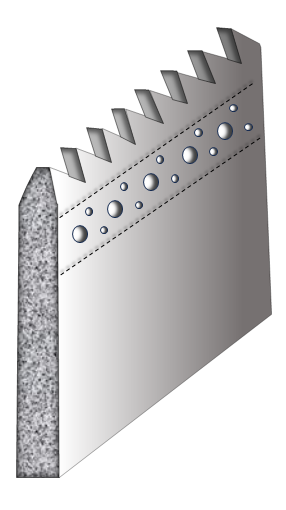

Gimped & Perforated Edge

A gimped & perforated edge serves both functional and decorative purposes. By introducing controlled perforations, the material bends more easily along curves. As a result, the edge turns smoothly without wrinkling.

This technique is frequently used in women’s footwear and heritage-style designs.

Benefits:

- Decorative enhancement

Pro Tip: Gimping

Use gimping selectively, since excessive perforation can weaken structural zones.

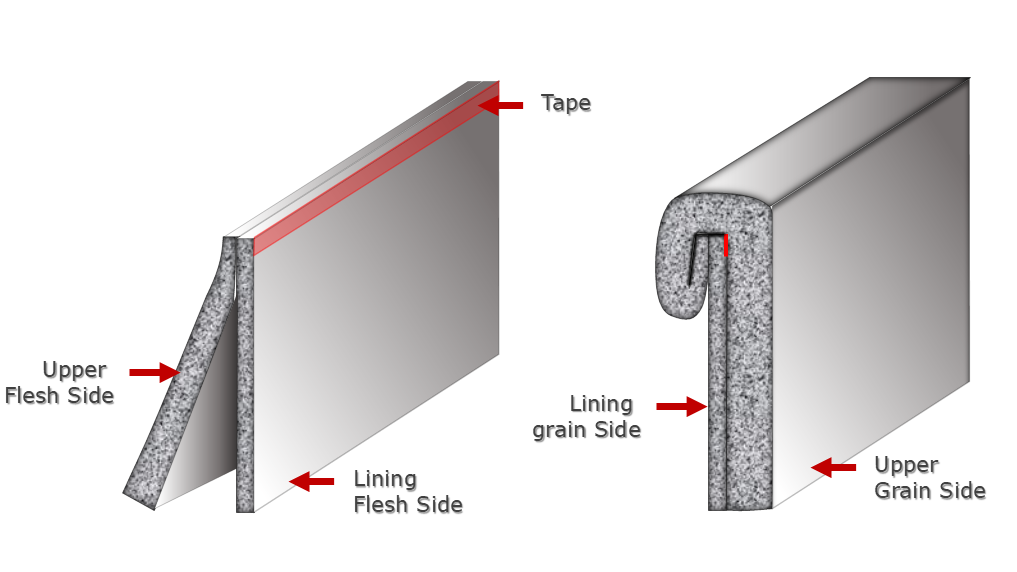

Bagging (Turned Topline)

Bagging creates a seamless topline with no visible top stitching. In this construction, the upper and lining are stitched grain-to-grain and then turned. Consequently, the topline appears refined and feels comfortable against the foot.

Bagging requires high precision. Even small errors in skiving or turn allowance can lead to visible defects or wearer discomfort.

Construction sequence:

- Stitch upper and lining grain-to-grain

- Maintain stitch distance at approximately 1.5 mm from edge

- Open and flatten the seam

- Turn the upper around the lining

- Apply adhesive to stabilise the topline

Standard measurements:

- Turn allowance: approximately 4-5 mm

- Skive width: approximately double the turn allowance

Pro Tip: Bagging

Maintain consistent turn allowance throughout the topline; otherwise, shape imbalance becomes visible during lasting.

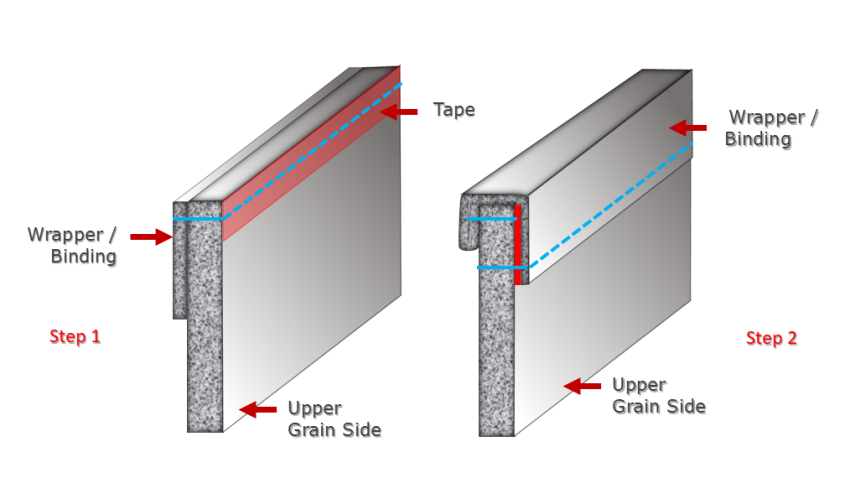

French Bound Edge (Slipper Binding)

French binding uses a narrow tape to reinforce and stabilize the topline. Because the tape restricts stretch, this method ensures long-term shape retention.

Process highlights:

- Stitching positioned very close to the tape edge

- Surplus binding folded neatly over

- Reinforcement tape often added

Pro Tip: French Binding

Keep the stitch line extremely close to the tape edge to avoid exposed binding after lasting.

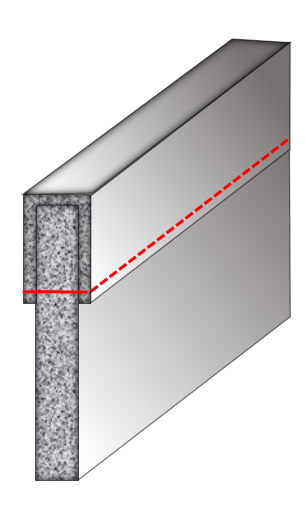

English Binding (U-Binding)

English binding, often referred to as U-binding, involves folding the binding material into a U-shape around the upper edge. Unlike French binding, this method allows moderate flexibility while still reinforcing the topline.

Characteristics

- Moderate strength

- Easier application

- Less refined appearance

Applications

- Unlined footwear

- Casual shoes

Pro Tip : English Binding

Use English binding where cost and speed matter more than premium finish.

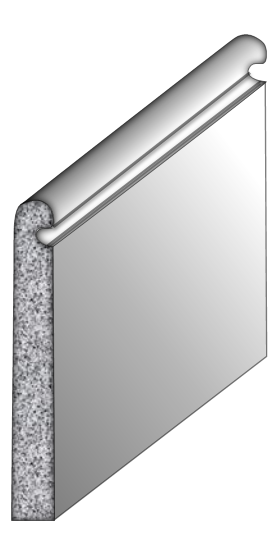

Slip Beading / Piping

Slip beading introduces a decorative rounded bead along the topline. This bead visually separates the upper and lining while also protecting the edge.

Functional Role

- Decorative contrast

- Visual definition

- Minor reinforcement

Design Notes

- Typically 6 mm wide

- Often used in contrasting colours

Pro Tip: Piping

Avoid overly soft materials for piping, as they collapse during lasting.

Collars

A collar is a separate strip attached inside the topline and turned outward. Therefore, collars significantly improve comfort in high-stress areas.

Purpose

- Cushioning

- Structural reinforcement

Common Use

- Sports shoes

- Casual footwear

Pro Tip: Collars

Ensure even padding distribution to prevent pressure points..

Ghillie Topline

The ghillie topline allows laces to pass through the topline itself. As a result, the shoe achieves adjustable fit without eyelets.

Construction Method

- Tubular folded strip

- Lace passes through channel

Applications

- Ghillie shoes

- Dance footwear

Pro Tip: Ghillie Topline

Reinforce lace entry points to prevent tearing.

Burnished Edge (Leather Only)

Burnishing involves passing a skived leather edge over a heated iron. This process contracts the grain, creating a rolled edge without folding.

Result

- Fold-like appearance

- No stitching required

Limitations

- Suitable only for leather

Pro Tip: Burnishing

Control temperature carefully, as overheating damages leather fibres.

Edge Inking

Edge inking enhances appearance and seals exposed fibres. Therefore, it is often used as a finishing or corrective process.

Common Methods

- Manual pen or wax

- Sponge or brush

- Rotary machine

Pro Tip: Inking

Apply multiple thin coats instead of one thick layer to avoid cracking.

Conclusion

Footwear edge finishing is not a single operation but a system of engineered techniques. By selecting the correct method, manufacturers achieve durability, comfort, and premium aesthetics simultaneously.