Development & Commercialization Process in Footwear

Footwear Creation: From Vision to Market Triumph

The journey of crafting footwear blends creativity, smart engineering, and careful planning. First, the Development phase turns fresh ideas into real samples buyers can see. Next, the Commercialization phase scales those designs into products that wow customers around the world. In this guide, we’ll explore each step—from the first prototype to the initial production run. You’ll get a clear roadmap for how top shoes come to life.

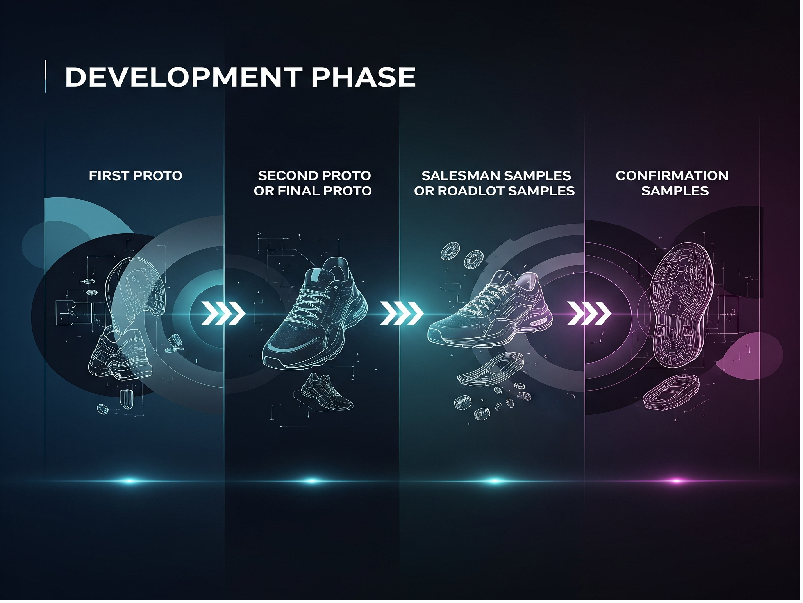

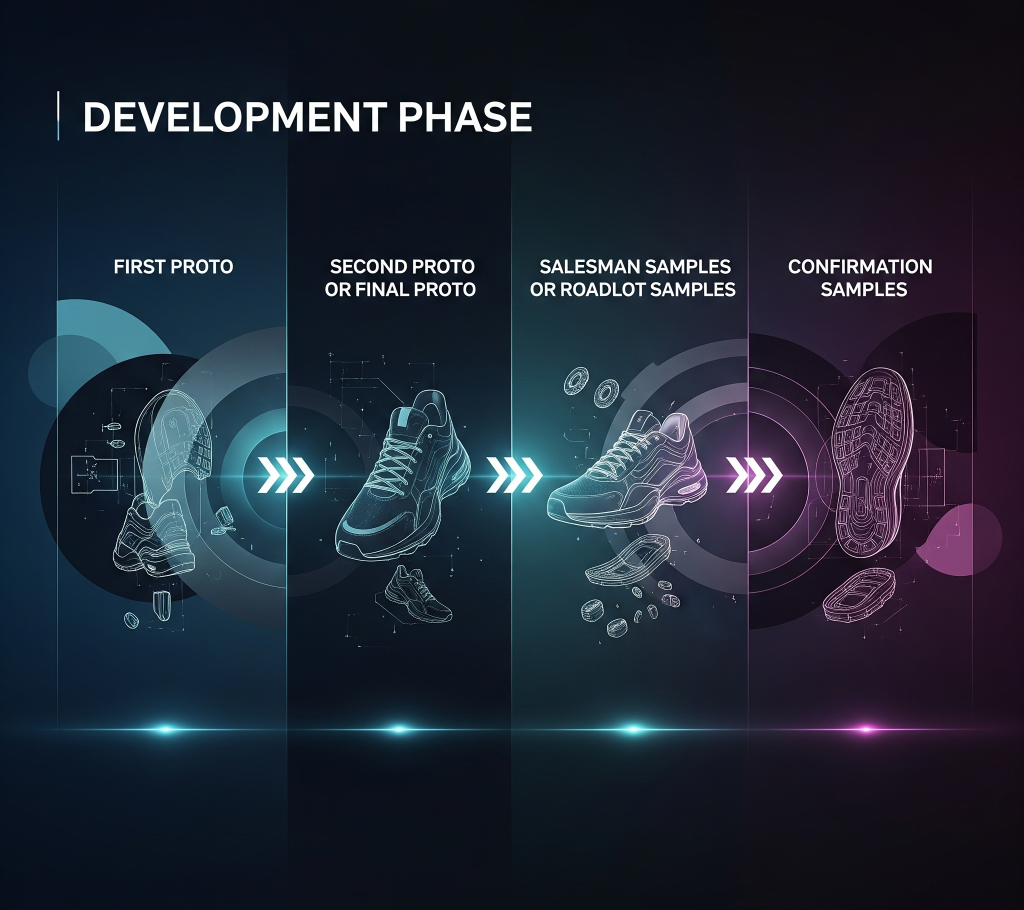

Development Phase: Building the Foundation

In the Development phase, new ideas become solid samples. This stage focuses on testing and refining. It prepares the shoe for sales pitches and factory plans. Let’s break it down step by step.

First Proto: The Starting Point

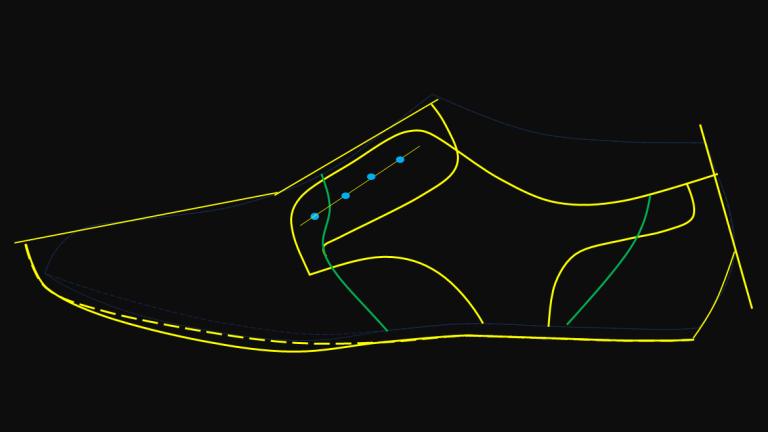

The First Proto is the first physical version of your shoe idea. It helps check if the design works in real life. Teams use tools like CAD software, 3D printing, or hand-building to make it. Often, they use basic materials for quick tests.

The goal? Test the shape, look, and basic fit. For instance, a new running shoe might try out a fresh cushioning idea with printed foam. Teams gather feedback from early reviews. In short, this stage sparks changes and sets the direction.

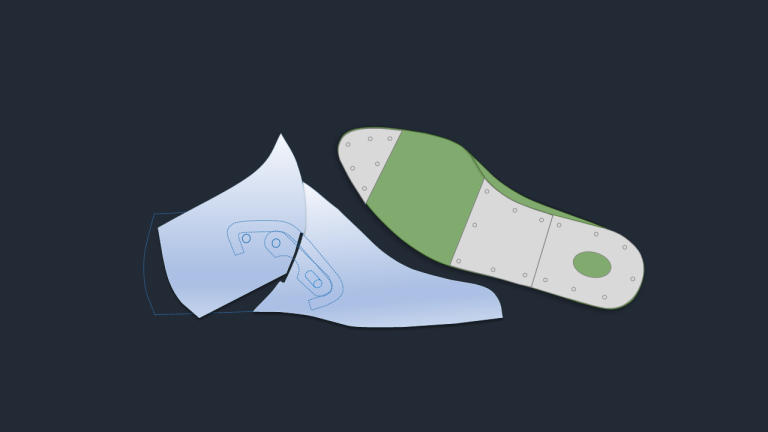

Second Proto or Final Proto: Fine-Tuning the Design

Next, the Second Proto or Final Proto improves the first version. It uses input from tests to get closer to the end goal. Engineers update the fit, pick real materials, and adjust building methods. These materials now match what factories will use.

Additionally, teams run wear tests and simple body-movement checks, like pressure maps for comfort. For example, if a hiking boot needs better ankle hold, they raise the edge and add padding here. Several rounds might happen to get it right. Overall, you end up with a smooth sample that shows the true style and use.

Salesman Samples (SMS) or Roadlot Samples: Showcasing to Buyers

Then come Salesman Samples (SMS) or Roadlot Samples. These are almost-ready versions to win over stores and buyers. Made in common sizes—like men’s US 9 or women’s US 7—they use factory-level materials and steps. They even add brand touches, such as logos and colors.

For example, Adidas might show these at a big retailer event to spotlight a cool sole feature. Meanwhile, they help spark early orders and build excitement. The result? A handful of top-quality samples that push sales forward.

Confirmation Samples: The Last Check

Finally, Confirmation Samples give the green light before big production. These use full factory methods and materials. Teams test fit, strength, and evenness closely. They check if the shoe hits goals, like good grip for sports models.

Any last fixes to the foot mold or patterns happen now. Take a dress shoe: a sample might get checked for leather wear and seam strength. In the end, you have approved samples ready for the next big phase

| Stage | Description | Key Activities | Deliverable |

|---|---|---|---|

| First Proto | Initial physical model to test design concept and feasibility. | – Create prototype using CAD, 3D printing, or handcrafting. – Test basic aesthetics, shape and fit. – Gather initial feedback. | Rough prototype with temporary materials. |

| Second Proto or Final Proto | Refined prototype addressing feedback from First Proto, closer to final design. | – Adjust fit, materials, and construction based on feedback. – Conduct wear tests and biomechanical analysis. – Finalize design details. | Final prototype with production-intent materials. |

| Salesman Samples (SMS) or Roadlot Samples | Near-final samples for sales and marketing to secure retailer orders. | – Produce small batch in standard size (e.g., men’s US 9). – Use production-grade materials and methods. – Present at trade shows or sales meetings. | Market-ready samples for buyer presentations. |

| Confirmation Samples | Final validation samples to confirm design and manufacturing readiness. | – Test for fit, durability, and quality consistency. – Approve for commercialization. – Finalize production specifications. | Approved samples ready for mass production. |

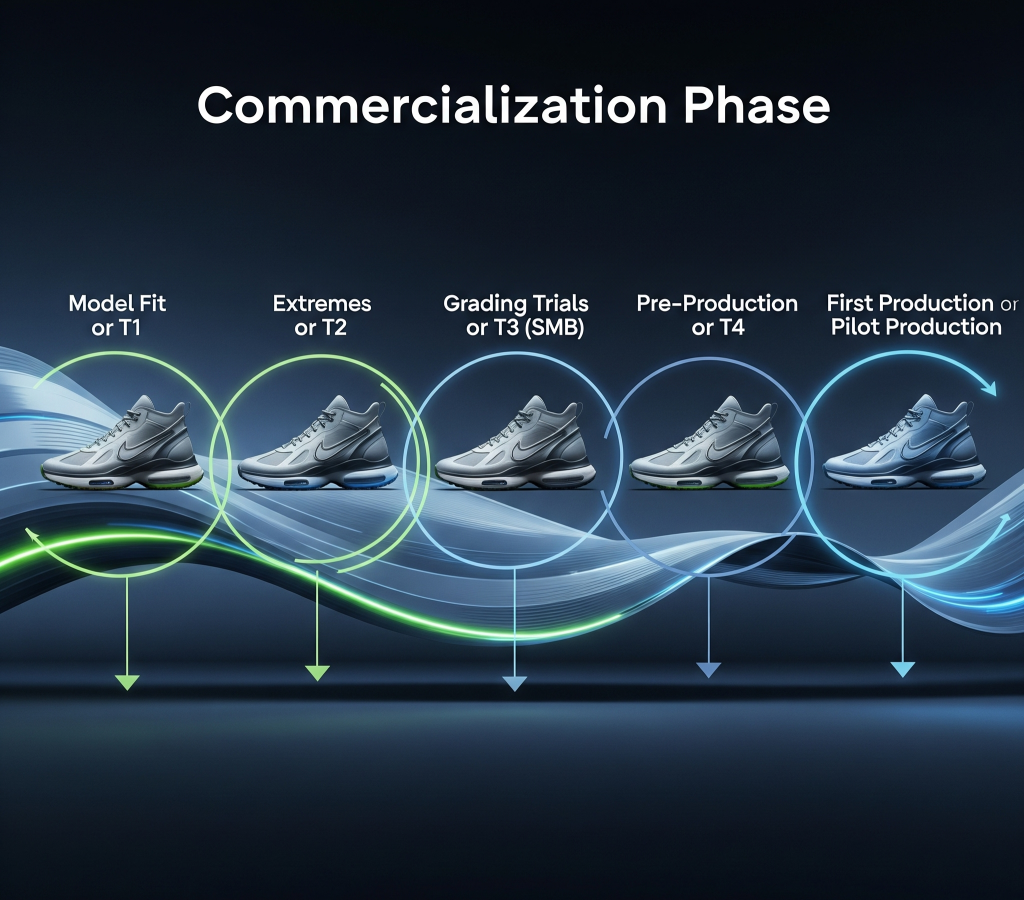

Commercialization Phase: Growing for Worldwide Reach

Now, the Commercialization phase takes those tested designs and preps them for factories and stores. It makes sure shoes fit everyone, pass quality checks, and hit shelves on time. We’ll cover each part below.

Model Fit or T1: Checking the Main Size

The Model Fit or T1 stage validates the shoe’s fit for the standard size, typically the average foot size for the target demographic (e.g., men’s US 9 or women’s US 6). Fit testers evaluate comfort, support, and performance, ensuring the shoe aligns with the brand’s standards. Adjustments to the last or patterns are made if issues like tightness or slippage arise. For example, a casual sneaker’s T1 sample might be tested for all-day comfort on a standard foot shape. The deliverable is an approved fit for the standard size, serving as the baseline for grading to other sizes.

Extremes or T2: Handling Edge Sizes

The Extremes or T2 stage ensures the shoe fit performs consistently in the extreme Sizes (the Bigger Middle sizes) in the range. Patterns are graded (scaled) from the model fit size, and samples are produced for these extreme sizes. Wear tests confirm that fit, proportion, and functionality remain intact, addressing issues like material stretching or structural integrity. For instance, a running shoe’s T2 testing ensures middle Size maintains the same cushioning and fit as a model size. The deliverable is a validated fit in the wider range, ready for broader testing.

Grading Trials or T3 (Small, Medium, Big): Testing the Range

The Grading Trials or T3 (SMB – Small, Medium, Big) stage tests fit and performance across a representative range of sizes (small, medium, and big) to ensure consistency. Samples are produced for these sizes, and wear tests verify that the shoe’s design intent—comfort, aesthetics, and functionality—holds true across the spectrum.

For example, a basketball shoe might undergo T3 testing to ensure traction and ankle support are consistent from small to large sizes. Final adjustments to grading patterns are made to prepare for making actual Tooling. The deliverable is a set of confirmed patterns for all production sizes.

Pre-Production or T4: Locking in Factory Details

The Pre-Production or T4 stage finalizes the product for mass manufacturing. A small batch of samples is produced using final materials, factory processes, and tooling (e.g., cutting knives, molds and lasts). These samples undergo extensive testing for quality, durability, and compliance with industry standards (e.g., ASTM for safety or chemical regulations). Packaging, such as shoeboxes and tags, is also finalized. For example, a pre-production batch of a sneaker might be tested for sole adhesion and stitching consistency. The deliverable is a set of production-ready samples and a fully equipped manufacturing setup, poised for the initial production run.

First Production or Pilot Production: Testing the Real Run

The First Production or Pilot Production stage marks the transition to mass manufacturing with an initial production run to test the factory process and ensure quality. A limited batch is produced on the assembly line, replicating the full-scale production environment. Quality control teams monitor for defects, such as inconsistent stitching or material flaws, and address any manufacturing issues. For instance, a pilot run of a hiking boot might identify and fix issues with sole bonding before scaling up.

This stage also aligns the supply chain—securing materials, coordinating factory capacity, and finalizing logistics—for full production. Marketing and distribution teams prepare for the market launch, ensuring retailers receive the product on schedule. The deliverable is an initial batch of market-ready footwear, ensuring a seamless rollout to retailers and consumers. This stage is critical for validating the production process, minimizing risks, and ensuring the footwear meets consumer expectations in quality and performance.

Different Stages of Commercialization

| Stage | Description | Key Activities | Deliverable |

|---|---|---|---|

| Model Fit or T1 | Validates fit for the standard size (e.g., men’s US 9 or women’s US 6). | – Test fit and comfort on Model foot size. – Adjust last or patterns if needed. – Confirm design aligns with brand standards. | Approved fit for standard Model size, ready for grading. |

| Extremes or T2 | Ensures fit and performance across smallest and largest sizes. | – Grade patterns to Bigger Middle Sizes – Test fit and functionality on extreme sizes. – Adjust for consistency. | Validated fit on the Bigger Sizes |

| Grading Trials or T3 (SMB – Small, Medium, Big) | Tests fit and performance across a range of sizes (small, medium, big). | – Produce samples in small, medium, and large sizes. – Conduct wear tests to ensure consistency. – Finalize grading patterns for tooling (Cutting Knives, Mold, Tooling, Last) | Confirmed patterns for all production sizes. |

| Pre-Production or T4 | Finalizes product for mass production with production-ready samples. | – Produce small batch with Actual Tooling, final materials, factory processes. – Test for quality, durability, and compliance (e.g., ASTM standards). – Finalize tooling and packaging. | Production-ready samples and manufacturing setup. |

| First Production or Pilot Production | Initial production run to test manufacturing process and quality. | – Conduct pilot run on factory line. – Monitor quality and address issues. – Prepare for full-scale production and market launch. | Initial batch of market-ready footwear. |

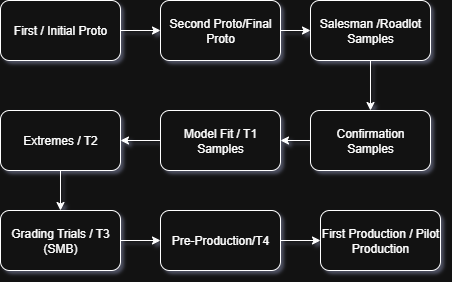

Development & Commercialization Flow Process Chart

Conclusion: A Step-by-Step Path to Success

The footwear development and commercialization process is a meticulously orchestrated journey, blending creativity, technical precision, and strategic planning. The Development phase crafts a vision into tangible, market-ready samples through iterative prototyping, while the Commercialization phase scales these designs into high-quality products ready for global markets. From the innovative spark of the First Proto to the polished execution of First Production, each stage ensures that the final footwear delivers on style, performance, and consumer expectations.

Note: This overview provides a standardized framework for the footwear development and commercialization process. Individual brands may adopt unique terminology and tailored approaches to align with their strategic goals and operational workflows.