Understanding Common Faults in Shoe Sole Bonding: Types and Likely Causes

Reading Time : 4 minutes

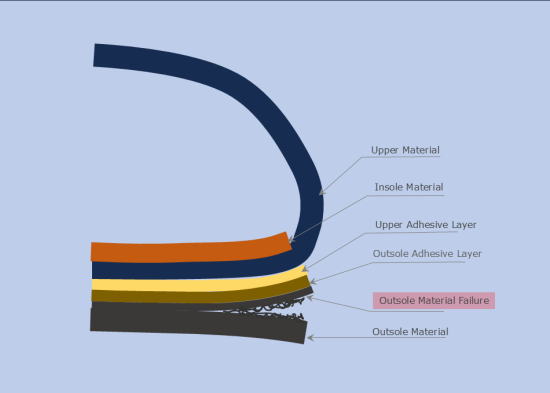

In footwear manufacturing, achieving a strong, durable bond between the upper and the sole is critical for shoe longevity and performance. When the bond strength is inadequate, soles can separate prematurely, leading to customer complaints and returns. The key to diagnosing issues lies in examining the type of separation after stripping the sole—this reveals the weakest link in the bond.

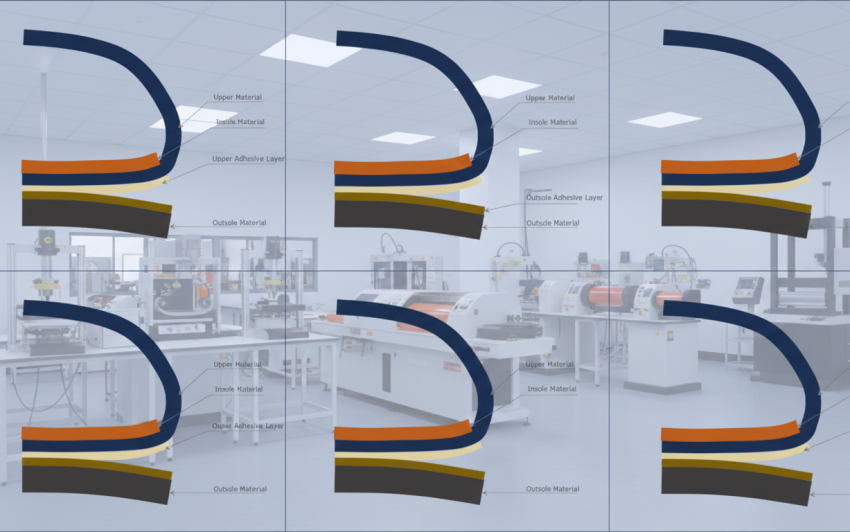

The primary links in a stuck-on sole bond are:

- Upper material

- Adhesion to upper

- Poor coalescence of adhesive film

- Cohesive failure

- Adhesion to sole

- Sole material

Below, we break down the various types of separation, their characteristics, and likely causes to help manufacturers and repair professionals troubleshoot effectively.

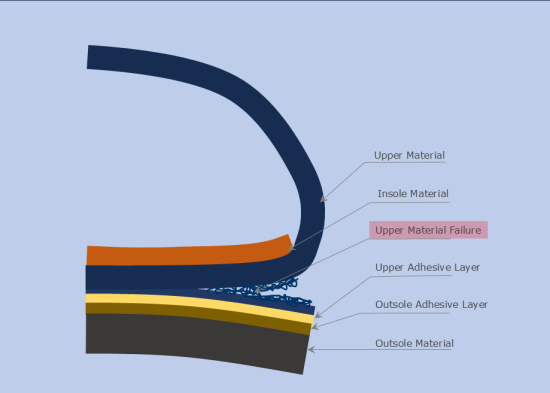

Upper Material Breakdown

When separating the sole, if it pulls away a layer of the lasted margin from the upper, this indicates failure within the upper material itself.

- A thick layer pulled away (deep separation) usually means the bond strength is satisfactory—the upper is the weaker component.

- A shallow layer suggests a potentially weak bond.

Common causes of weak bonds with upper failure:

- Separation of lacquer or top finish from plastic-coated fabrics—always remove with solvent wiping before cementing.

- Inherently weak materials like goat leather.

- Weak surface layers not properly roughed (e.g., grain of leather or coatings on PU-coated fabrics).

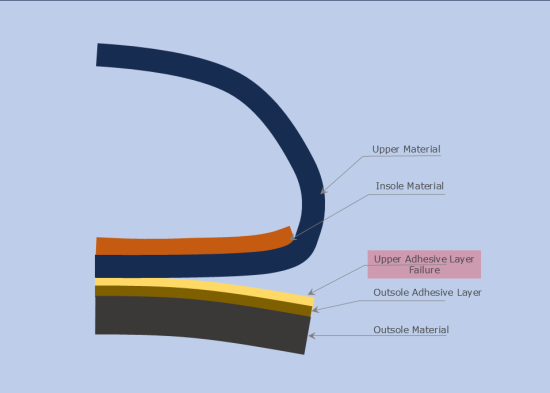

Adhesion Peeling from Upper

This clean peel from the upper surface typically signals an inadequate bond.

Possible causes:

- Insufficient roughing of leather, preventing adhesive penetration.

- Greasy or contaminated leather/material surfaces.

- Incompatibility between adhesive and upper material (e.g., nylon or certain plastics/textiles require special priming, scouring, or roughing).

- Inadequate surface preparation, such as failing to remove lacquer or contaminants via roughing or solvent wiping.

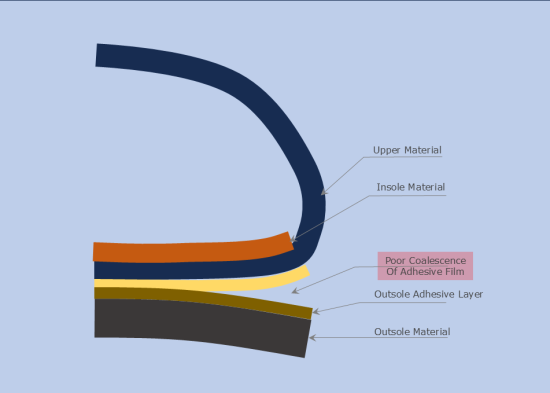

Poor Coalescence of Adhesive Film

A frequent issue identified by shiny patches where the two adhesive films (on upper and sole) fail to merge properly.

Likely causes:

- Insufficient heat reactivation.

- Insufficient or uneven pressure during attaching (check for excessive pleats, ill-fitting soles, thick fillers, or incorrect press pads).

- Stale adhesive film from exceeding the supplier’s open time between cementing and assembly.

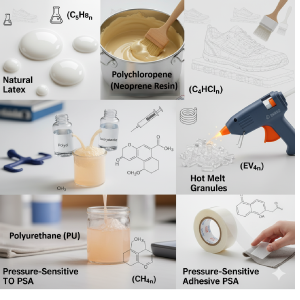

- High grease content in upper leather (polychloroprene adhesives are especially vulnerable).

- Excessive adhesive penetration leading to a “starved” surface.

- Incompatible adhesives used on sole and upper

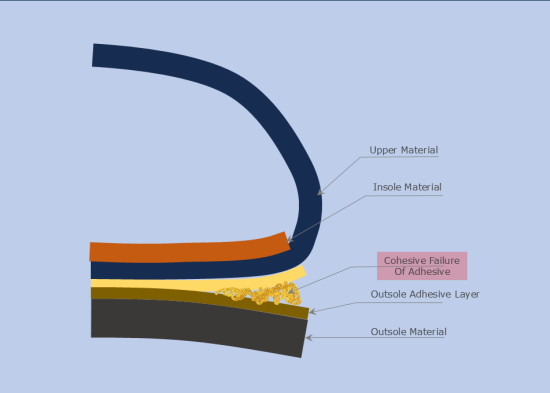

Cohesive Failure of Adhesive

Characterized by “legging” of the adhesive—strings form as the joint separates, with tacky adhesive remaining on both surfaces.

Causes include:

- Too short drying time, resulting in solvent retention.

- Insufficient press time for adhesive to cool after heat reactivation.

- Softening from plasticizer migration (e.g., from PVC) or grease from leather.

- Exposure to high temperatures during storage or wear.

- Over-heating during reactivation, causing excessive softening.

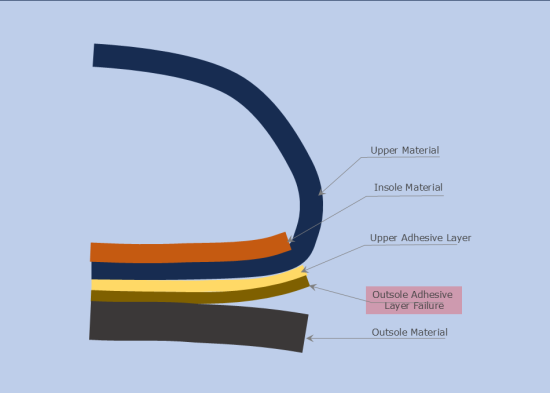

Adhesive Peeling from Sole

A clean peel from the sole side indicates poor adhesion here.

Reasons:

- Incorrect roughing on outsoles (insufficient for penetration).

- Inadequate preparation of rubber soles (mechanical/chemical halogenation needed to remove stale surfaces or contamination).

- Poor preparation of plastic soles (remove mold release agents or lacquers; ensure surface receptivity).

- Exhausted active chemicals in primers.

Breakdown Within the Soling Material

Failure occurs deep within the sole material itself, often meaning the bond is stronger than the sole—similar to upper breakdown.

Likely Causes

- Poor material formulation

- Aging or degraded outsole compounds

- Excessive brittleness or softness

Conclusion

Sole bonding failures are rarely random—they always leave evidence. By closely examining the mode of separation, footwear manufacturers can identify whether the issue lies in material quality, surface preparation, adhesive selection, or process control.

A structured approach to bonding diagnostics not only improves bond reliability but also reduces rework, customer complaints, and long-term quality costs. In footwear manufacturing, bond analysis is not just troubleshooting—it is preventive quality engineering.