Abrasive Papers in Footwear Manufacturing: Types, Grit Sizes, Materials, and Applications

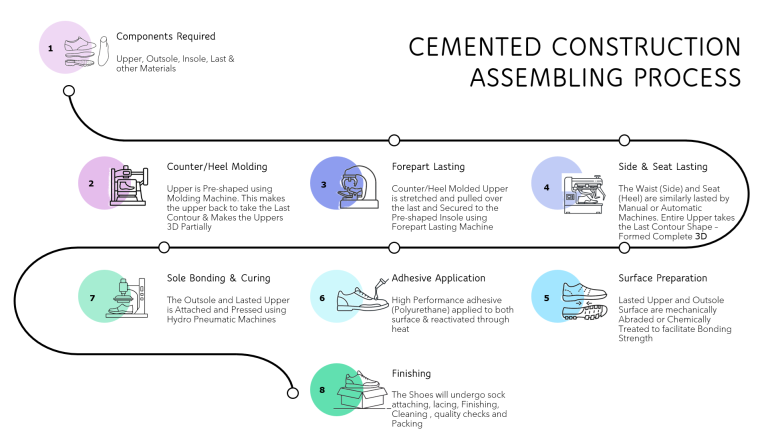

Abrasive papers play a critical role in footwear manufacturing by enabling controlled material removal, surface preparation, smoothing, and finishing across multiple shoe components. In footwear operations such as lasting, making, heel scouring, bottom scouring, and finishing, abrasives act through the movement of hard abrasive particles that mechanically remove softer materials brought into contact with them.

In practice, abrasives function by a microscopic “chiselling” action. As the abrasive surface moves, each particle cuts into the substrate, removing material incrementally. Therefore, the size, hardness, and durability of the abrasive particles directly influence cutting speed, surface texture, and final appearance. Larger particles remove material more rapidly but leave a coarser finish. Conversely, extremely fine particles remove minimal material and produce a smoother, polished surface.

In footwear finishing, this principle is especially evident during heel scouring. Initially, coarse abrasives remove surface irregularities. Subsequently, finer abrasives smooth the surface and prepare it for colouring, inking, and polishing. To achieve any level of gloss, a polished surface must be built upon a smooth foundation that is free from scratch marks.

Classification of Abrasive Materials Used in Footwear

Abrasive materials used in footwear manufacturing fall into two broad categories: naturally occurring abrasives and manufactured abrasives. Each category offers distinct characteristics that influence suitability for specific footwear processes.

Natural Abrasive Materials Used in Footwear

Flint (Quartz)

Flint, also known as quartz, is a naturally occurring abrasive obtained from crushed mineral sources. The particles are typically off-white in colour, although they are often dyed red or black for identification. In footwear manufacturing, flint has traditionally been used for heel scouring. However, it wears out quickly and, as a result, is seldom used in modern shoe production where durability and consistency are required.

Garnet

Garnet is another natural abrasive produced from crushed mineral sources. It has a reddish-brown particle colour and is widely recognised for its ability to cut fast and clean. In footwear applications, garnet is commonly used for heel scouring where efficient material removal is required without excessive surface damage.

Emery

Emery is a dull black abrasive obtained from crushed mineral deposits. It is typically supplied in stick form. Emery contains iron oxide, also known as jeweller’s rouge, which makes it suitable for polishing operations. In addition, aluminium oxide within emery contributes to its abrasive properties. Although emery is suitable for metal applications, it is generally not recommended for shoe materials due to compatibility limitations.

Pro Tip: Process Control : Maintain a structured grit progression during finishing. Skipping grit steps increases scratch visibility during polishing and colouring, leading to rework and inconsistent cosmetic quality.

Manufactured Abrasive Materials in Footwear Applications

Glass Abrasives

Glass abrasives are produced from ground-up waste glass and appear off-white in colour. These abrasives are commonly referred to as “sandpaper.” However, in footwear manufacturing, glass abrasives are not widely used because they tend to tear the surface rather than produce controlled abrasion, which compromises material quality.

Carborundum (Silicon Carbide)

Carborundum, also known as silicon carbide, is manufactured by melting sand and coke together in a furnace. The resulting abrasive particles are bluish-black in colour. This abrasive is considered ideal for leather and other shoe materials due to its sharp cutting ability and consistent performance. Furthermore, carborundum is also used in grindstones, reinforcing its reputation as a high-performance abrasive.

Aluminium Oxide (Various Trade Names)

Aluminium oxide is manufactured by melting bauxite clay in a furnace. The abrasive particles typically appear dull yellow-brown in colour. Aluminium oxide is recognised as the toughest and most durable abrasive material used in footwear manufacturing. Although it is not as sharp as carborundum, its extended life makes it suitable for grindstones and long-duration scouring operations where durability is essential.

Make-Up of Abrasive Papers Used in Footwear Factories

Abrasives are supplied to the footwear industry in various widths and shapes to fit specific machines. These include rolls designed for bottom scouring machines, cross-sectional shapes for heel scouring rolls, and continuous bands used on band scouring machines.

The backing material of abrasive papers is usually one of the following. Strong, flexible paper is commonly used for general scouring applications. Cloth backing, typically heavy twill or drill fabric, provides higher strength and flexibility. In some cases, a combination of both paper and cloth is used to balance durability and flexibility.

The abrasive particles are attached to the backing material using an adhesive designed to resist high operating temperatures. This heat resistance is critical, as friction during scouring generates significant heat that can otherwise degrade bonding strength.

Related Posts

Understanding Grit Size in Footwear Abrasive Papers

The size of abrasive particles is referred to as the grit size. Grit size is determined by grading the particles through a series of open mesh sieves, with each sieve becoming progressively smaller. The grit number corresponds to the size of the mesh that prevents the particle from passing through. For example, a 60-grit abrasive is retained by a mesh containing 60 openings per inch.

As a rule, the smaller the grit number, the coarser the abrasive. Conversely, higher grit numbers indicate finer abrasives. In shoe manufacturing, grit sizes typically range from 20, which is very coarse, to 220, which is fine.

Typical Applications of Abrasive Papers in Footwear Manufacturing

Lasting and Making Operations

During toe pleat scouring, abrasive papers with grit sizes ranging from 20 to 40 are commonly used. These coarse grits efficiently remove excess material formed during lasting.

For upper scouring, which is often an alternative to roughing, different materials require different grit ranges. Leather uppers typically use grits between 24 and 40. PU and PVC uppers require grits between 30 and 40. Poromeric materials generally perform best with grit sizes between 24 and 36.

Finishing Operations

Heel scouring during finishing is carried out in multiple stages. Rough scouring uses grit sizes between 40 and 80. Fine scouring employs grits ranging from 100 to 180. Superfine scouring uses very fine grits between 200 and 220 to prepare the surface for colouring and polishing.

During the “rolling-in” of colour, the back of the scouring paper is used rather than the abrasive surface, ensuring even colour distribution without surface damage.

Bottom scouring also requires graded abrasive selection. Rough bottom scouring uses grits between 150 and 180. Fine bottom scouring uses grits between 180 and 220. Breast scouring typically uses a grit size of 120, while nankee scouring commonly uses grit sizes around 180.

Pro Tip: Selection Mistakes : Using metal-grade abrasives or overly sharp materials on shoe components can tear surfaces instead of scouring them. Always select abrasives specifically suited for leather, PU, PVC, or poromeric materials.

Heat Generation and Control During Abrasive Operations

One of the most significant challenges when using abrasive papers in footwear manufacturing is the heat generated by friction. This heat increases with higher pressure applied to the scouring paper or cloth, increased cutting surface speed, clogging of abrasive particles with dust, and wearing down of the abrasive particles themselves.

Excessive frictional heat can cause burning of shoe materials. Since machine speed is usually fixed, operators must control other factors. Avoiding excessive pressure reduces heat build-up. Keeping the work moving across the abrasive prevents heat concentration in one area. Changing abrasive paper or cloth when worn or clogged also maintains cutting efficiency and reduces overheating.

In some cases, the life of an abrasive can be extended by lightly touching the abrasive surface with a ball of crepe rubber. This action removes dust that causes clogging and restores cutting performance.

Pro Tip: Common Defects : Burn marks, glazing, and uneven finishes often indicate excessive pressure or clogged abrasives. Immediate replacement or cleaning of the abrasive surface prevents permanent material damage.

Installing Abrasive Papers on Footwear Scouring Machines

When installing abrasives on scouring rolls, whether continuous band or jointed types, it is essential to check the backing paper or cloth for directional arrows or indicators. These markings show the intended direction of operation. Ensuring that the arrow travels in the same direction as the rotation of the roll improves efficiency, reduces clogging, and significantly extends abrasive life.