Stitch and Seam Construction in Footwear Manufacturing: Types, Formation Methods, and Practical Applications

Stitch and seam construction is a critical foundation of footwear manufacturing, as it directly affects shoe durability, comfort, structural integrity, and visual quality. Every footwear upper is assembled from multiple components that must be securely joined while still allowing flexibility and resistance to repeated stress during wear. Therefore, selecting the correct stitch type and seam construction is essential for achieving consistent quality in mass production.

This article explains the most commonly used stitch types and seam constructions in footwear, focusing on how they are formed, where they are applied, and why they are important in professional shoe manufacturing.

Stitch Types Used in Footwear

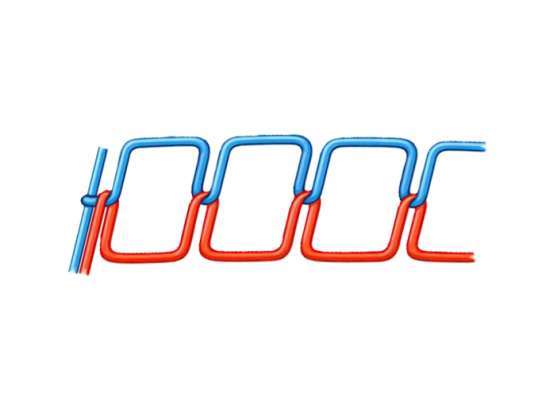

Lockstitch

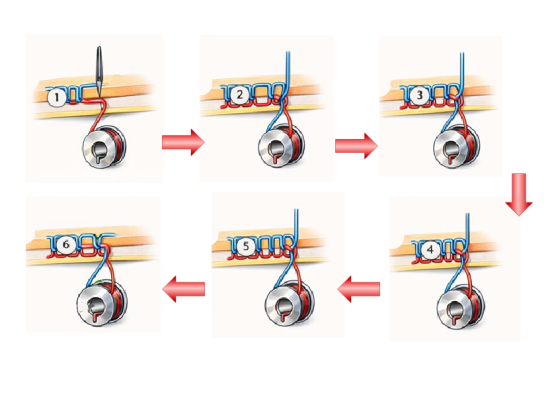

The lockstitch is the most widely used stitch in footwear production due to its excellent seam security and balanced appearance. It is formed using two separate threads: one thread passes through the needle from the top, while the second thread is supplied from a bobbin located beneath the sewing machine. These two threads interlock between the material layers, creating a stable locking point.

Because the locking point is positioned within the material, the stitch remains secure even when footwear components are subjected to repeated flexing. As a result, lockstitch is commonly used in areas where both durability and appearance are critical, especially when the stitch is visible on both sides of the upper.

Key characteristics of lockstitch:

- Two-thread construction using needle and bobbin

- Identical stitch appearance on face and flesh sides

- High resistance to seam unraveling

However, bobbins hold a limited amount of thread. Therefore, frequent bobbin changes are required, which may slightly reduce production efficiency in high-volume manufacturing.

Pro Tip: Stitch Selection in High-Flex Areas

When stitching components near the toe flex point or ball area, seam security should always be prioritized. Although chainstitch improves production speed, lockstitch is generally preferred in high-flex zones because it reduces the risk of seam failure caused by continuous bending during wear.

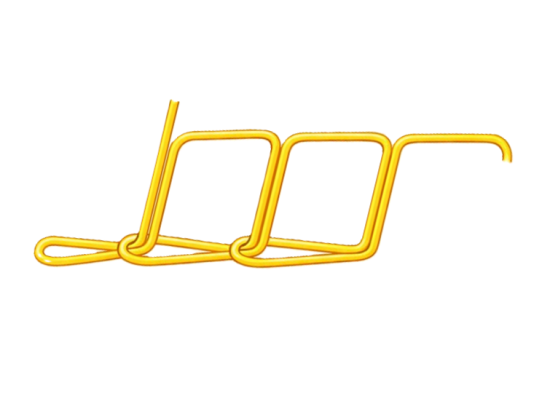

Chainstitch

Chainstitch differs from lockstitch because it does not require a bobbin thread. Instead, the stitch is formed by looping one or more threads on the underside of the material, creating a chain-like structure. This construction allows continuous stitching without frequent thread changes.

In footwear manufacturing, chainstitch is valued for its higher production efficiency and reduced machine downtime. Since no bobbin is used, longer sewing runs can be completed without interruption.

There are two commonly used types of chainstitch in footwear:

- Single-thread chainstitch, formed by looping one thread on itself

- Double-thread chainstitch, formed using a needle thread and a looper thread

Despite its efficiency advantages, chainstitch has one limitation. If the stitch breaks at one point, the seam may unravel. Therefore, it is typically used in non-visible areas or where reinforcement is applied.

Pro Tip: Choosing Between Lockstitch and Chainstitch

In high-volume production, chainstitch machines are often selected to increase output. However, when seam appearance is visible on both sides of the upper, lockstitch provides a cleaner and more consistent finish. The final stitch choice should always balance efficiency, durability, and aesthetic requirements.

Stitch Formation and Machine Adjustment

Stitch formation involves a precise interaction between the needle, hook or looper, thread tension devices, and feed mechanisms. For correct stitch formation, the locking or looping point must be accurately positioned within the material layers.

If stitch adjustment is incorrect, issues such as loose stitches, uneven tension, seam puckering, or premature seam failure may occur. Therefore, proper machine setup and regular adjustment are essential to maintain consistent stitch quality throughout production.

Pro Tip: Preventing Thread Damage During Sewing

Thread damage is often caused by excessive heat generated during high-speed stitching. This can result from incorrect needle size, worn needles, or poor lubrication. Regular needle replacement and correct thread-to-needle matching significantly reduce thread breakage and extend seam life.

Seam Construction in Footwear

Importance of Seam Construction

Seam construction determines how footwear components are joined and how stresses are distributed during walking, flexing, and lasting. In addition, seam type influences comfort, water resistance, appearance, and material utilization.

If seam construction is poorly selected or incorrectly executed, problems such as seam failure, discomfort, or customer complaints are likely to arise. Therefore, seam selection must always consider the upper material, shoe design, and functional performance requirements.

Common Seam Types Used in Footwear

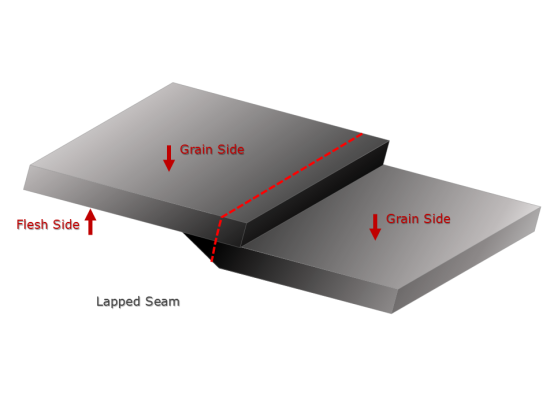

Lapped Seam

The lapped seam is the most commonly used seam in footwear manufacturing. In this construction, one component overlaps another and is secured using one or more rows of stitching. This seam is widely preferred because it offers:

- High seam strength

- Good reinforcement capability

- Compatibility with most upper materials

Lapped seams are frequently used in leather uppers and in areas subjected to higher stress.

Pro Tip: Reinforcement Is Not Always Visible

Reinforcement tapes or backing materials are often added inside lapped seams but remain invisible in the finished shoe. These hidden reinforcements play a major role in improving seam strength and preventing long-term separation during wear.

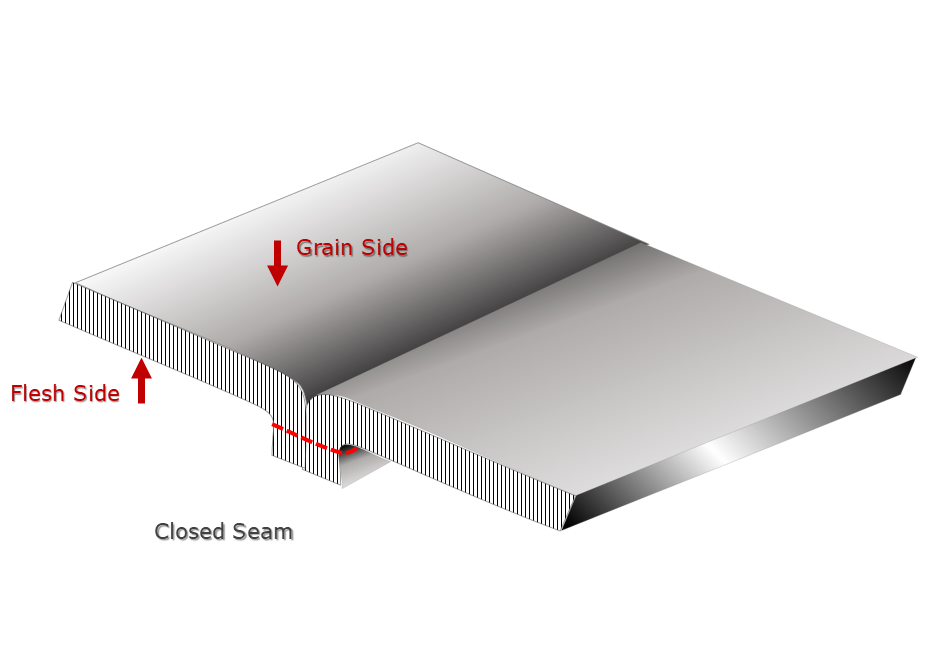

Closed Seam

In a closed seam, components are stitched face-to-face and then turned, so the raw edges are concealed inside the seam. This results in a clean and refined external appearance.

Because material edges are enclosed, thickness control becomes critical. Skiving is usually required to reduce bulk, and reinforcement tape may be added after stitching to improve durability.

Pro Tip : Seam Thickness Control Is Critical

Many seam failures are caused not by stitching defects but by excessive seam thickness. Proper skiving before closed seam construction improves lasting performance and significantly enhances wearer comfort.

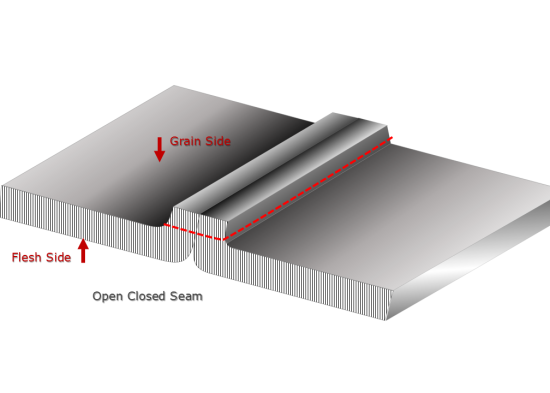

Open Seam

An open seam is a variation of the closed seam, where the seam allowance is opened flat after stitching. This produces a flatter internal structure and reduces localized thickness.

Open seams are commonly used in:

- Lightweight footwear

- Fashion-oriented designs

- Uppers where flexibility is required

Although the seam is less bulky, careful edge preparation is still necessary to maintain strength.

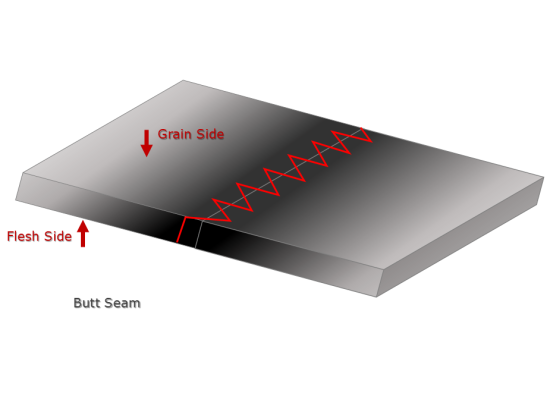

Butted Seam

In a butted seam, two material edges are placed edge-to-edge and joined using a zigzag stitch. Often, a backing material is added underneath the joint to improve strength.

This seam construction helps maintain uniform thickness across the upper, which improves comfort. However, precise cutting and accurate alignment of edges are essential to avoid weak joints.

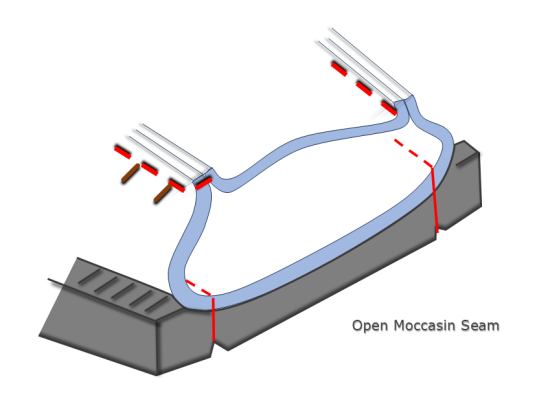

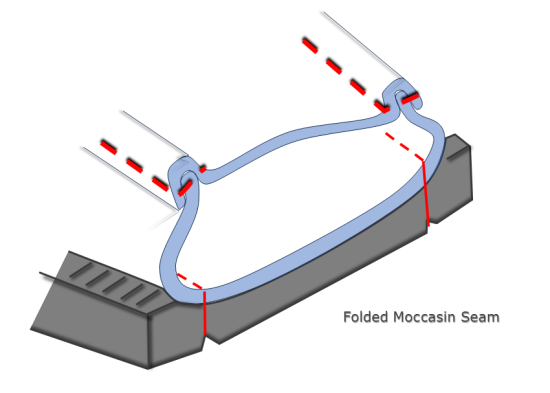

Moccasin Seam

The moccasin seam is commonly used in casual and comfort footwear. In this construction, material edges are joined using overlapping or interlocking stitches, either by hand or machine.

This seam provides a distinctive handcrafted appearance while allowing greater flexibility in the upper.

Pro Tip: Moccasin Seams Require Skilled Handling

Although moccasin seams appear simple, they require precise tension control and consistent stitch spacing. Uneven stitching can distort the upper shape and negatively affect visual symmetry, especially in premium footwear.

Sprung Seam

A sprung seam, also known as a springing seam, is used when joining components of different shapes or lengths. During stitching, one component is slightly compressed so both pieces can be joined accurately.

This technique enables three-dimensional shaping of the upper and improves fit during lasting.

Pro Tip: Use Sprung Seams to Improve Lasting Accuracy

Sprung seams help reduce material stress during lasting and contribute to a cleaner upper profile. When applied correctly, they improve fit consistency and reduce lasting-related defects.

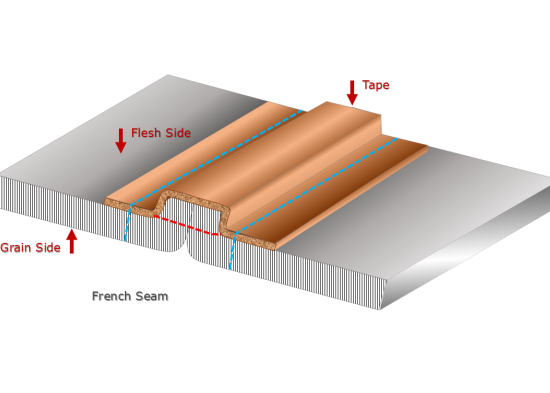

French Seam

The French seam is a refined seam construction designed to produce a neat, enclosed finish on both sides of the seam. It is formed by stitching the components together, folding the seam allowance, and stitching again so that all raw edges are fully enclosed within the seam structure.

This seam type is valued for its clean appearance and smooth internal finish, making it suitable for footwear styles where comfort and internal aesthetics are important. However, because multiple stitching operations are required, careful thickness control and precise execution are essential.

Key characteristics of the French seam:

- Fully enclosed raw edges

- Clean and refined appearance

- Smooth internal surface for improved comfort

Pro Tip: Control Thickness When Using French Seams

French seams should only be used on thin or well-skived materials. Without proper thickness control, the seam may become bulky, affecting lasting accuracy and wearer comfort.

Brooklyn Seam

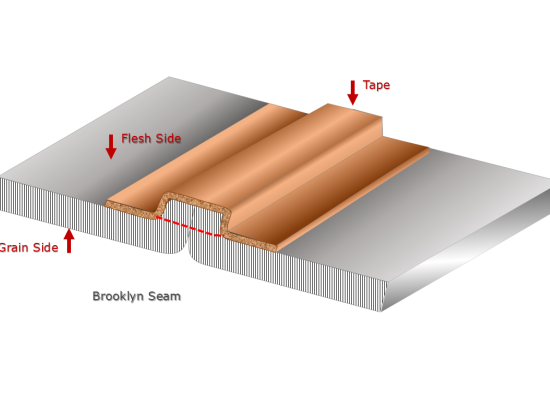

The Brooklyn seam is a reinforced variation of the closed seam, developed to provide additional seam strength and durability without significantly increasing seam bulk. In this construction, the seam is first produced in the same manner as a standard closed seam. After stitching, an adhesive or woven reinforcement tape is rubbed down over the seam allowance and secured, strengthening the joint.

Because the reinforcement is applied internally, the external appearance of the seam remains clean while the internal structure gains improved resistance to stress and separation. As a result, the Brooklyn seam is commonly used in footwear areas subjected to repeated flexing or moderate load.

Key characteristics of the Brooklyn seam:

- Based on a standard closed seam construction

- Reinforced with adhesive or woven tape

- Improved seam strength without visible bulk

Key characteristics of the Brooklyn seam:

- Based on a standard closed seam construction

- Reinforced with adhesive or woven tape

- Improved seam strength without visible bulk

Pro Tip: Use Brooklyn Seams for Durability Without Design Impact

When additional seam strength is required but external appearance must remain unchanged, Brooklyn seams are an effective solution. They are particularly useful in leather uppers where reinforcement is needed without altering the visual design lines.

Conclusion

In footwear manufacturing, stitch and seam construction plays a decisive role in determining product quality, durability, and customer satisfaction. While lockstitch offers superior seam security and appearance, chainstitch improves production efficiency. Similarly, each seam type—from lapped seams to moccasin seams—serves a specific functional and aesthetic purpose.

By understanding and applying the correct stitch and seam construction methods, footwear manufacturers can significantly enhance both performance and visual appeal of their products.