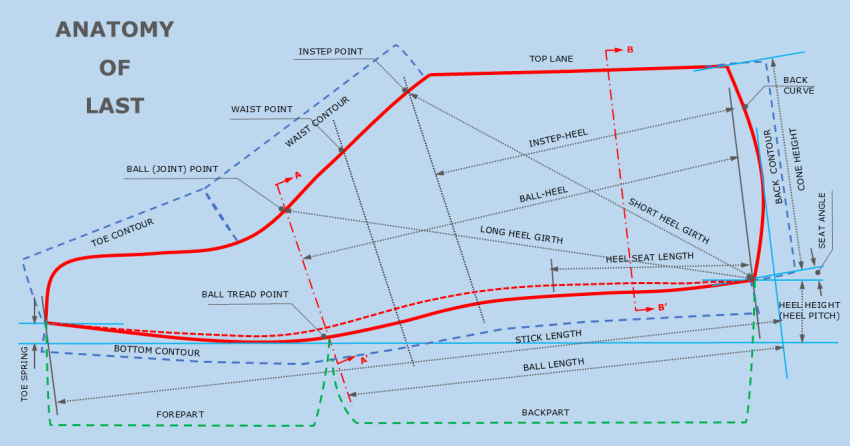

Comprehensive Glossary of Shoe Last Anatomy Terms

Reading Time : 19 minutes

Introduction

The shoe last forms the foundational mold in footwear manufacturing, replicating human foot anatomy to deliver precise fit, comfort, stability, and aesthetic appeal. This exhaustive glossary compiles all key terms from shoemaking references, covering measurements, contours, construction types, and materials. It serves as an authoritative resource for professionals in design, production, orthopedics, and bespoke craftsmanship to ensure accuracy and innovation.

Glossary of Shoe Last Terms

Aluminum Lasts

Aluminum lasts are durable molds used primarily for sole molding in high-temperature processes. They withstand oven conditions in mass production, ensuring consistent shape retention. In shoemaking, these lasts facilitate efficient vulcanization and injection molding, ideal for athletic and industrial footwear requiring robust structural integrity.

Arch Spring

Arch spring denotes the upward curvature in the last’s arch area, supporting the foot’s natural bend. It influences shoe flexibility and energy return during gait. Shoemakers adjust this for orthopedic designs, enhancing comfort for high arches and reducing fatigue in prolonged use scenarios.

Back Curve

The back curve on the shoe last follows the heel’s rear shape, providing a secure grip around the Achilles area. It prevents heel slippage and blisters by contouring precisely to the foot. Shoemakers refine this curve for better ankle support, essential in boots and dress shoes for both aesthetics and functional integrity.

Backpart

The backpart covers the rear of the last, from the waist to the heel, focusing on support structures. It ensures heel security and ankle stability. In shoemaking, this part integrates counters and padding, vital for preventing injuries in boots or orthotics, combining rigidity with cushioned fit.

Ball (Joint) Point

The ball joint point marks the widest part of the forefoot on the shoe last, corresponding to the metatarsal heads. It is essential for width fittings, allowing flexibility and preventing pressure points. Accurate sizing here ensures toes can spread naturally, enhancing walking comfort and reducing the risk of blisters or deformities.

Ball Girth

Ball girth measures the circumference around the ball joint on the last, determining forefoot volume. It ensures adequate space for metatarsal expansion under load. In design, this measurement prevents constriction, crucial for wide feet or athletic shoes, promoting circulation and minimizing pressure-related issues.

Ball Length

Ball length measures from the heel to the ball joint point on the last, focusing on forefoot positioning. It is key for alignment in multi-part lasts. This dimension helps tailor shoes to gait patterns, preventing misalignment issues like bunions, and enhancing overall foot health in custom designs.

Ball Line

Ball line is a reference mark across the widest forefoot section on the last, guiding pattern alignment. It ensures proportional upper construction. Shoemakers use this for precise cutting, balancing aesthetics with fit in various styles, reducing material waste and improving manufacturing efficiency.

Ball Reach

Ball reach measures the horizontal distance from the heel seat to the ball joint point along the last’s bottom profile. It ensures proper alignment of the foot’s flex point with the shoe’s break line. Accurate ball reach prevents discomfort during gait, supporting natural rollover and reducing strain in dynamic footwear designs.

Ball Tread Point

The ball tread point is the contact area on the bottom contour of the last where the ball of the foot bears weight. It guides sole design for traction and cushioning. In shoemaking, this point optimizes weight distribution, promoting natural gait and durability, especially in athletic or high-heel shoes.

Ball-Heel

The ball-heel distance measures from the ball joint to the heel seat, defining the last’s overall length balance. Critical for sizing accuracy, it accommodates foot elongation under weight. Shoemakers use this to prevent heel lift or toe crunching, optimizing comfort in varied footwear like sneakers or formal shoes.

Bottom Contour

The bottom contour traces the underside profile of the shoe last from toe to heel, forming the base for the sole. It ensures even weight distribution and arch support. In design, this contour affects traction and flexibility, adapting to different terrains and activities for enhanced stability.

Combination Last

Combination last features a heel two sizes narrower than the ball width, creating shoes with slim heels and wide toe boxes. It addresses varied foot shapes. In production, this last enhances fit for pronation control, suitable for orthopedic and custom footwear applications.

Cone

The cone refers to the tapered upper heel section on the last, shaping ankle enclosure. It influences boot and high-top designs. Shoemakers refine the cone for seamless upper integration, ensuring support without bulk, critical for elegance and functionality in formal or protective shoes.

Cone Angle

The cone angle on the last measures the slant at the upper heel cone, affecting how the shoe wraps the ankle. It balances openness with hold. This angle is pivotal in boot design, allowing easy entry while maintaining form, adapting to calf variations for inclusive sizing.

Cone Height

Cone height refers to the vertical rise at the last’s back cone area, shaping the upper heel contour. It influences ankle coverage and support. In design, accurate height ensures seamless upper attachment, enhancing elegance in dress shoes while providing structural integrity against wear.

Connectional Hinge Last

Connectional hinge last employs a linked hinge mechanism for forepart and backpart separation. It facilitates removal in closed shoe constructions. This type supports precise lasting in oxfords and boots, maintaining shape integrity during assembly and allowing adjustments for custom fits.

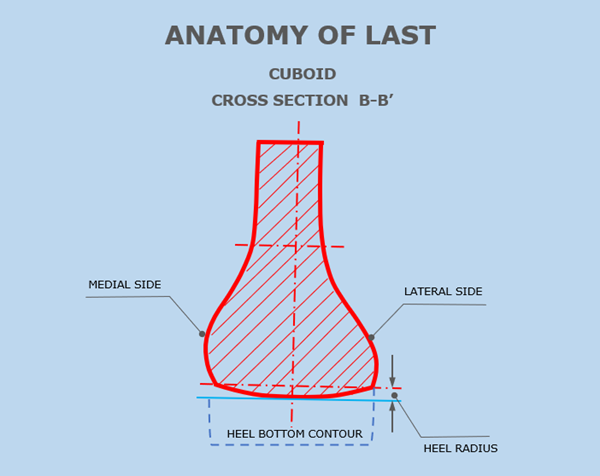

Cuboid

The cuboid area on the last corresponds to the Lasts Cross section of Mid Heel portion (40-60mm from the heel towards toe Area). It ensures foot fitting at the Mid-Heel Upper portion.

Degree

Degree on a shoe last indicates the height variance between the heel’s front and back edges. It fine-tunes balance and posture. This metric helps in orthopedic adjustments, correcting pronation issues by aligning the foot properly for therapeutic or performance-enhancing footwear.

Forefoot

The forefoot on the last spans from ball to toes, shaping the front’s width and flexibility. It supports natural splay during push-off. This area is key for ventilation features, adapting to high-impact uses like sports, blending protection with agility for injury prevention.

Forepart

The forepart encompasses the front section of the shoe last, from the waist forward, including toe and ball areas. It shapes the shoe’s toe box and flexibility. Crucial for toe freedom, it adapts to activities like running or dancing, balancing protection with natural foot splay.

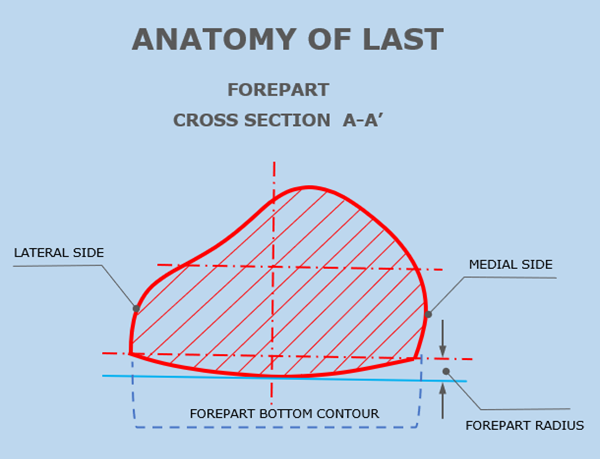

Forepart Bottom Contour

Forepart bottom contour outlines the underside curve from ball to toe on the last, guiding forefoot sole design. It promotes smooth rollover and cushioning. In shoemaking, this contour optimizes traction in dynamic movements, essential for sports shoes to reduce impact and improve efficiency.

Forepart Radius

Forepart radius measures the curvature radius in the last’s front section, affecting toe box roundness. It determines bottom curvature of the Foot and the last. Shoemakers use this for aesthetic precision, ensuring comfort by preventing bottom compression in fashion-forward or ergonomic designs.

Heel Bottom Contour

Heel bottom contour traces the underside heel profile on the last, forming the base for heel stability. It influences shock absorption and balance.

Heel Radius

Heel radius defines the curvature radius at the last’s heel back, shaping counter fit. . Shoemakers optimize this for ankle support.

Heel Seat Length

Heel seat length spans the flat base area under the heel on the last. It supports weight distribution and shock absorption. This measurement influences heel cushioning design, vital for comfort in prolonged standing, adapting to different heel shapes for personalized fit and reduced impact stress.

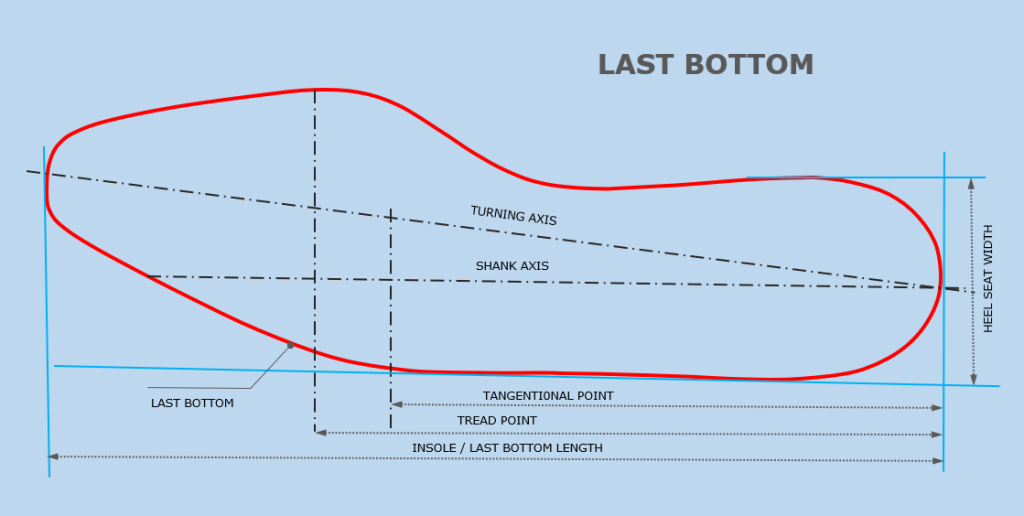

Heel Seat Width

Heel seat width measures across the last’s heel base, defining rear stability. It prevents lateral shifts during movement. Shoemakers use this for narrow or wide heels, enhancing grip in athletic and dress shoes to minimize blisters and improve overall structural support..

Hinge

Hinge refers to the pivoting mechanism in articulated lasts, allowing forepart and backpart separation. It aids shoe removal post-lasting. This feature is essential for boots and closed designs, enabling adjustments while preserving shape during repeated manufacturing cycles.

Instep Girth

Instep girth measures circumference over the last’s instep, assessing midfoot volume. It ensures secure fit without compression. In customization, this dimension accommodates high insteps, critical for comfort in lace-up shoes and reducing pressure on tendons during extended wear.

Instep Point

The instep point on a shoe last refers to the highest point along the top plane where the arch of the foot meets the shin area. It plays a crucial role in determining the shoe’s fit over the midfoot, ensuring comfort and support during wear. Proper measurement prevents slippage or tightness.

Instep-Heel

The instep-heel measurement spans from the instep point to the heel seat on the shoe last, gauging midfoot length. It is vital for proportional fitting, ensuring no gaps or pressure. This dimension aids in customizing shoes for different strides, promoting alignment and reducing strain on tendons.

Joint Girth (Same as Ball Girth)

Joint girth, identical to ball girth, measures the circumference around the ball joint on the last at the metatarsal heads. It determines forefoot volume for natural flex. Accurate joint girth prevents constriction, essential for width fittings and comfort in athletic or wide-fit footwear.

Last

The last is the three-dimensional mold replicating the human foot’s shape, serving as the core form in footwear construction. It determines overall fit, style, and functionality. Shoemakers use lasts made from wood, plastic, or metal to shape uppers and soles, ensuring consistency in sizing and comfort across production.

Last Balancing

Last balancing involves adjusting the last’s weight distribution and alignment for symmetrical shoe production. It ensures even sole wear and posture. Shoemakers perform this to correct manufacturing variances, essential for high-quality bespoke footwear that maintains foot health and aesthetic consistency.

Last Bottom

Last bottom refers to the entire underside surface of the last, serving as the template for sole shaping. It dictates traction and support patterns.

Last Bottom Instep Width

Last bottom instep width measures the lateral span across the underside at the instep area. It influences midfoot sole stability and volume distribution.

Last Bottom Joint Width

Last bottom joint width measures the lateral dimension across the underside at the ball joint point. It defines forefoot base stability and sole width. Precise measurement here supports natural toe splay, essential for athletic and orthopedic designs to reduce pressure points.

Last Bottom Length

Last bottom length measures along the underside from toe to heel, providing a flattened sizing reference. It standardizes sole dimensions. Shoemakers use this for accurate pattern scaling, ensuring compatibility with foot lengths while accounting for curves in mass or custom production.

Last Bottom Plates

Last bottom plates are protective metal sheets affixed to the last’s underside, preventing damage from tacking. They support reusable lasts. This feature is crucial in welt construction, allowing secure upper attachment without compromising last integrity in high-volume shoemaking.

Last Bottom Seat Width

Last bottom seat width measures the lateral span across the heel seat underside. It ensures rear sole stability and heel anchoring. Shoemakers optimize this for secure fit, preventing wobble in high heels or work boots and enhancing overall balance during wear.

Last Bottom Waist Width

Last bottom waist width measures the lateral dimension across the underside at the narrowest arch area. It supports shank placement and midfoot stability. Accurate waist width prevents twisting, vital for arch support in athletic or high-arch footwear designs.

Last Bottom Width

Last bottom width assesses the lateral dimension across the last’s underside at key points. It influences sole stability and fit. Shoemakers refine this for wide-base designs, ensuring balance and preventing rollover in athletic or orthopedic footwear applications.

Last Down Curve

The down curve is the longitudinal curvature of a shoe last from heel to toe, determining toe spring, walking movement, shoe posture, and overall comfort by supporting smooth heel-to-toe foot motion.

Last Hinges

Last hinges are mechanical joints enabling last segmentation for easy shoe extraction. They vary by type for specific designs. This mechanism supports efficient production, maintaining precision while allowing adjustments for diverse footwear constructions.

Last Pins

Last pins are metal rods or hinges used in articulated lasts to connect forepart and backpart sections. They enable precise pivoting for shoe removal. Durable pins maintain alignment, essential in hinged lasts for boots and closed constructions during repeated manufacturing.

Long Heel Girth

Long heel girth is the circumferential measurement taken around the heel and Ball area of a shoe last, controlling heel fit, slip resistance, and rear-foot comfort in finished footwear.

Moccasin Lasts

Moccasin lasts feature specialized shapes for seamless upper wrapping, often with sliding hinges. They ensure soft, flexible fits. Used in traditional moccasin construction, these lasts prioritize comfort and minimal structure, adapting to casual or indigenous footwear styles with precise contouring.

Mono-Block Construction

Mono-block construction describes solid, non-hinged lasts without openings, used for open footwear. It provides uniform shaping. In sandal production, this design simplifies molding, ensuring stability and ease in assembly for styles requiring minimal adjustment.

Sandal Lasts

Sandal lasts closely match foot dimensions, with wide insoles and mono-block builds for open constructions. They accommodate ankle fastenings. Used for sandals, these lasts prioritize natural fit and ventilation, adapting to casual designs with minimal enclosure for breathability.

Scoop Hinge Last

Scoop hinge last utilizes a scooped joint for enhanced flexibility in removal, suitable for complex shapes. It maintains structural alignment. This type aids in crafting boots, allowing precise lasting while minimizing distortion in high-quality productions.

Seat

Seat denotes the heel base area on the last, providing foundational support. It integrates with counters for stability. Shoemakers contour the seat for secure heel placement, essential in preventing slippage and ensuring balance in diverse shoe architectures.

Shank Axis

Shank axis runs longitudinally through the last’s waist, guiding arch reinforcement placement. It ensures structural rigidity. In design, aligning shanks along this axis prevents twisting, critical for high-heel lasts to maintain posture and durability under load.

Short Heel Girth

Short heel girth is the circumferential measurement taken around the heel and instep area of a shoe last, controlling heel fit, slip resistance, and rear-foot comfort in finished footwear.

Sliding Hinge

Sliding hinge enables lateral separation in lasts for moccasin or tight constructions. It facilitates non-destructive removal. This mechanism supports seamless wrapping, vital for soft-soled shoes, ensuring fit accuracy without compromising last reusability in specialized crafting.

Slidomatic Hinge Last

Slidomatic hinge last incorporates an automated sliding joint for efficient part separation. It streamlines production workflows. Used in mass manufacturing, this last type enhances speed in boot and shoe assembly, maintaining precision for consistent quality outputs.

Solid Last

Solid last lacks hinges or openings, providing a rigid form for simple constructions. It ensures unyielding shape retention. Ideal for sandals or flats, this type simplifies molding, focusing on durability and basic fit in entry-level or traditional shoemaking.

Standard Last Length

Standard last length tapes from the heel featherline rear to the toe front, setting baseline size. It standardizes across manufacturers. Crucial for international fitting, this ensures consistency, allowing precise scaling for widths or heights in mass production or bespoke shoemaking.

Stick Length

Stick length is the straight-line measurement from the heel back (Highest point) to the toe tip along the last’s bottom, used for basic sizing. It standardizes shoe lengths across styles. Shoemakers rely on this for consistent production, ensuring compatibility with foot measurements while allowing adjustments for variations.

Straight Lasted

Straight lasted design creates symmetrical shoes without inward curve, aiding pronation correction. It promotes neutral alignment. Shoemakers employ this for therapeutic footwear, enhancing stability for overpronators and reducing joint stress in daily or athletic applications.

Tangential Point

Tangential point marks where curves meet smoothly on the last, such as at waist transitions. It ensures seamless contours. In patterning, this point guides precise cuts, vital for elegant silhouettes and ergonomic fits in bespoke or fashion shoes.

Telescopic Hinge Last

Telescopic hinge last features extendable joints for adjustable length, accommodating varied designs. It offers versatility in fitting.

Thimble

Thimble in last context refers to a protective metal cap on hinge pins, preventing wear. It ensures mechanism longevity. Shoemakers value this for hinged lasts, maintaining smooth operation in repetitive lasting processes for manufacturing.

Toe

The toe section on the last defines the front tip’s shape and height, influencing style from square to almond. It provides space for digit movement. Shoemakers craft this for aesthetic appeal while ensuring no pressure, essential in pointed shoes to avoid deformities and promote healthy toe alignment.

Toe Allowance

Toe allowance adds extra length beyond the foot’s toe on the last, varying by style. It prevents visible insole in opens. In pump designs, this ensures aesthetic appeal, balancing roominess with form in pointed or rounded configurations.

Toe Box Height

Toe box height measures the vertical space from the last’s bottom to the top over the toes, ensuring ample room. It prevents compression on nails or joints. Shoemakers adjust this for breathability and protection, vital in work boots to accommodate swelling or orthotics for all-day wear.

Toe Contour

The toe contour outlines the curved shape of the last’s front end, mimicking the foot’s toes for a natural fit. It determines toe box roominess, preventing cramping while allowing movement. Shoemakers use this to craft stylish yet functional tips, balancing fashion trends with foot health.

Toe Plate

Toe plate is a reinforced section on the last’s toe bottom, guarding against abrasion. It supports durable patterning. Used in heavy-duty lasts, it facilitates secure tacking, essential for work boots to maintain accuracy in rugged constructions.

Toe Profile

Toe profile defines the lateral silhouette of the last’s toe, influencing style from almond to square. It affects aesthetic and fit. Shoemakers tailor this for trend compliance, ensuring toe freedom without excess volume in dress or casual footwear.

Toe Spring

Toe spring is the upward curve at the last’s toe end above the ground plane, promoting smooth rollover in gait. It reduces tripping risks and eases forward motion. Essential in running shoes, this feature absorbs shock, enhancing efficiency and comfort over long distances without sacrificing durability.

Toe Thickness

Toe thickness measures vertical depth at the last’s toe, determining box height. It provides cushioning and protection. In design, adjusting thickness accommodates nail health, crucial for enclosed shoes to prevent compression and support swelling in prolonged wear.

Top Plane

The top plane is the upper flat surface of the shoe last, running from the instep to the back curve. It shapes the shoe’s upper structure, influencing lace or strap placement. Crucial for fit customization, it accommodates varying foot volumes, ensuring breathability and security..

Top Surface Profile

Top surface profile traces the curved outline of the last’s upper surface from toe to heel. It defines instep height, waist taper, and cone shape. Shoemakers refine this profile for ergonomic fit, ensuring smooth upper draping and comfort across diverse foot volumes.

Tread Point

Tread point identifies the primary ground contact area on the last’s bottom, often at the ball. It guides sole patterning. Shoemakers optimize this for grip and wear resistance, vital in outdoor shoes to enhance traction and longevity on varied surfaces.

Turning Axis

Turning axis is the rotational centerline for last shaping in manufacturing. It ensures symmetrical contours. In last production, aligning to this axis prevents distortions, key for precision in wooden or plastic forms used across footwear types.

Unisex Last

Unisex last is designed to accommodate both male and female foot proportions in a single mold, often with neutral widths and volumes. It simplifies production for gender-neutral styles. This last balances average dimensions, enabling versatile footwear lines while maintaining adequate fit for diverse users in casual or athletic designs.

Vamp

Vamp marks the forward upper section on the last, from toe to instep. It influences coverage and style. Shoemakers use vamp points for pattern placement, ensuring seamless integration in lace-ups or pumps for both function and visual appeal.

Waist Contour

The waist contour defines the curved narrowing along the sides of the last at the arch area. It enhances foot arch support and shoe stability. In crafting, this contour allows for elegant tapering, improving fit for high arches or flat feet, and contributing to durability.

Waist Girth

Waist girth encircles the last at the narrowest arch section, measuring midfoot constriction. It provides stability against shifts. This dimension is essential for arch support in athletic designs, preventing collapse and ensuring lightweight yet secure fits.

Waist Plate

Waist plate reinforces the last’s arch underside, protecting during lasting operations. It maintains curve integrity. In production, this plate supports shank installation, crucial for rigid constructions like high heels to enhance load-bearing capacity.

Waist Point

The waist point is the narrowest section of the shoe last, located between the ball and the heel. This measurement point ensures the shoe hugs the foot’s arch snugly, providing stability and preventing side-to-side movement. In shoemaking, it influences the overall silhouette and ergonomic support.

Wedge Angle

The wedge angle calculates the slant between the heel’s front and back heights on the last, influencing pitch stability. It supports even weight shift. In wedge designs, this angle provides subtle elevation, combining fashion with ease, reducing calf strain compared to traditional heels.

Width

Width quantifies lateral dimensions at ball, instep, or waist on the last, denoted by letters. It accommodates foot breadth variations. Shoemakers scale widths for inclusive sizing, ensuring circulation and comfort without squeezing in standard or specialized footwear.

Wooden Shoe Last

Wooden shoe last, typically maple, is hand-carved for bespoke fits based on foot measurements. It offers superior contouring. Preferred in artisanal shoemaking, this last type ensures personalized comfort, adapting to unique anatomies for high-end or orthopedic applications.

Conclusion

This complete glossary of shoe last terms provides professionals with comprehensive knowledge to advance footwear design, manufacturing, and customization. Mastery of these elements enables creation of products that excel in fit, durability, performance, and inclusivity across diverse applications.