Footwear Manufacturing Insights: Backseam & Boot Vamp Spring Adjustment

Reading Time : 3 Minutes

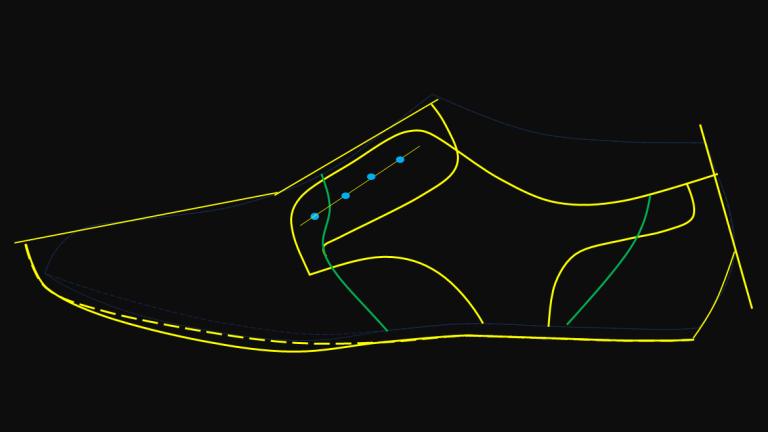

Small pattern-making details often decide whether a shoe looks refined or amateurish after lasting. Two commonly overlooked areas are backseam construction without a backstrap and adjusting the spring of boot vamps. Though simple in concept, these techniques greatly influence heel smoothness, fit comfort, and lasting quality. This article explains both methods using proven pattern practices widely used in footwear manufacturing.

Backseam Without Backstrap

In footwear designs where a backstrap is not used, maintaining a clean and stable backseam becomes critical. A well-executed backseam ensures heel symmetry and prevents bulging or ridging after lasting.

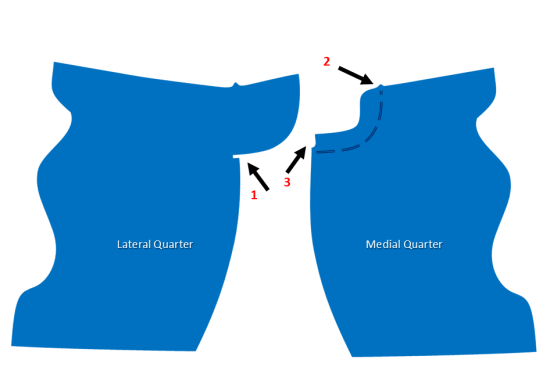

The key lies in two small but essential notches, commonly marked as “1” and “2” in the pattern.

- This small cut (1) in lateral quarter allows the two quarter pieces to close smoothly during stitching. Without this relief cut, material accumulation occurs at the back-seam, creating an unsightly bump at the heel center.

- The small notch (2) at medial quarter, serves as a reference point for stitching the heel dog-tail ensuring consistent folding allowance during lasting. It helps the operator maintain correct alignment when closing the back-seam.

- Small recession (3) at the medial quarter is to reduce bulginess.

Practical Benefit:

This method delivers a smooth heel profile, clean seam closure, and stable structure—without the need for a reinforcing backstrap.

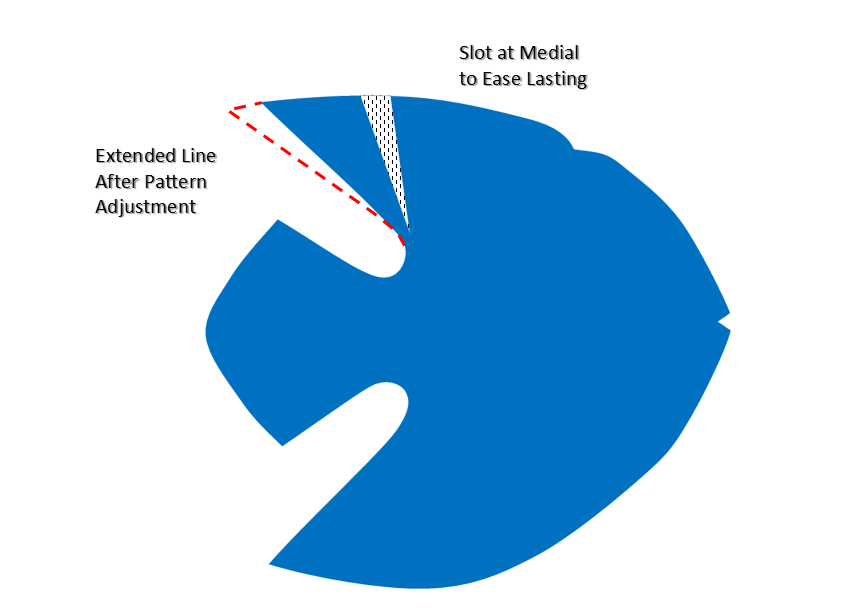

Boot Vamp Spring Adjustment

Boot vamps often experience excess tension on the inside (Medial) waist area, especially in higher or structured designs. If not corrected at the pattern stage, this tension causes discomfort and poor lasting behavior.

The solution is a controlled incision in the vamp standard pattern:

- A small vertical cut is introduced in the waist region.

- The cut is opened slightly, as shown by the hatched area in the diagram.

- This adjustment redistributes leather toward the inside of the foot.

Key Advantages:

- Improves inside fit without changing external appearance

- Reduces stress during stitching and lasting

- Makes vamp closing easier without complicating operations

Importantly, this modification does not affect vamp stitching difficulty and does not require extra components.

Conclusion

Both techniques highlight how minor pattern adjustments produce major quality improvements. Correct notch placement in backseams ensures clean heel finishing, while controlled spring adjustment in boot vamps improves fit and manufacturing ease. For footwear professionals, mastering these small details leads to consistent quality, better comfort, and fewer production issues.