Types of Shoes and Shoe Construction – A Beginner’s Guide

Footwear is more than just fashion — it combines function, comfort, material science, and craftsmanship. Whether you work in manufacturing, design, or retail, understanding the types of shoes and their construction methods builds a strong foundation.

Types of Shoes

The construction method directly influences comfort, flexibility, price, and durability. Here are the main ones:

Based on Usage:

Type | Description |

Sports Shoes | Designed for running, training, or specific sports |

Casual Shoes | Everyday comfort wear (sneakers, loafers) |

Formal Shoes | For office, meetings, events (Oxfords, Derbies) |

Safety Shoes | Industrial footwear with steel toe, anti-slip |

Sandals/Slippers | Open footwear for casual/home use |

Boots | Covers ankle and above (work boots, Chelsea) |

Kids Footwear | Designed with soft materials and flexible soles |

Types of Shoe Construction

Shoe construction affects comfort, flexibility, price, and durability.

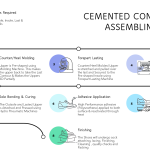

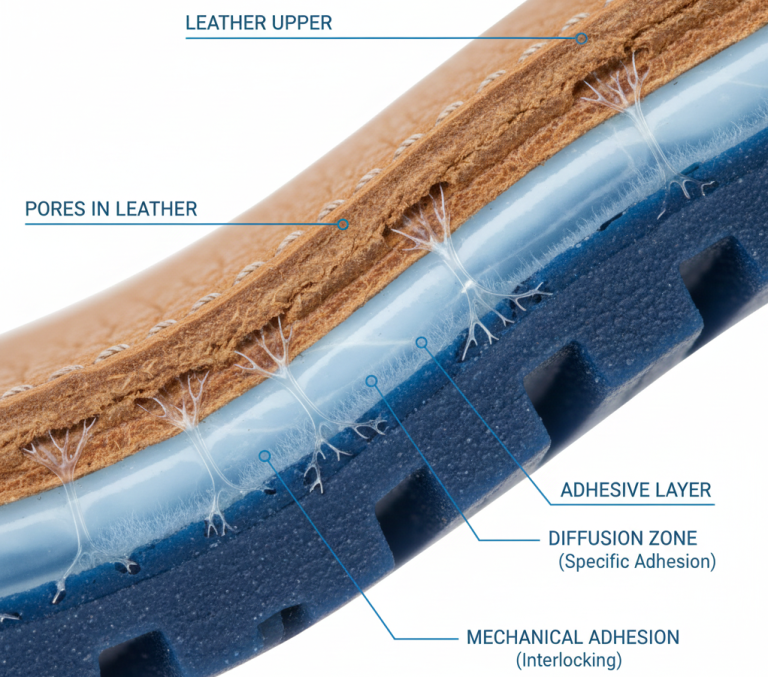

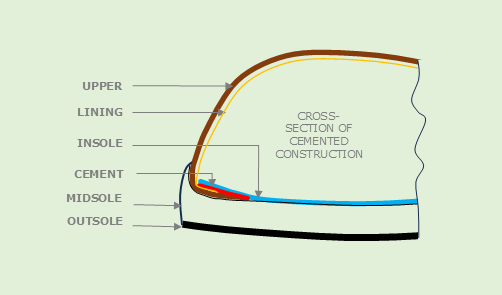

A. Cemented Construction

- Most Common in Sports and Casual Shoes

- Upper is Glued directly to the Outsole

- Pros – Lightweight, Flexible

- Cons – Cannot be Resoled

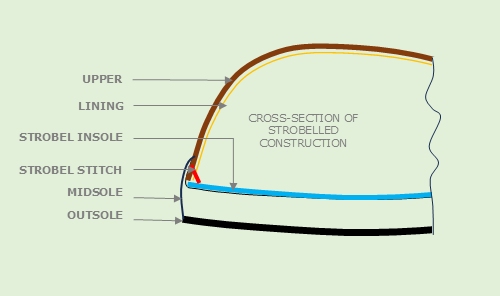

B. Strobel Construction

- Used in Sports / Fabric Shoes

- A Strobeled Board is stitched to the Upper, then glued to the Outsole

- Pros – Soft, Flexible and Fast Production

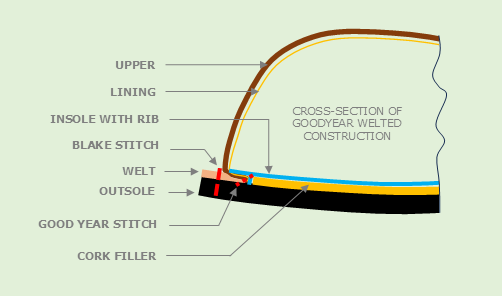

C. Goodyear Welted

- Mostly in leather / Forma Shoes

- Upper Stitched to a Leather Welt, then to the Outsole

- Pros – Durable & Resoleable

- Cons – Heavier & Expensive

D. Direct Injection Process (DIP)

- Mostly used for safety shoes and some kids shoes

- Outsole is molded directly onto upper using PU

- Pros – Strong Outsole Bonding

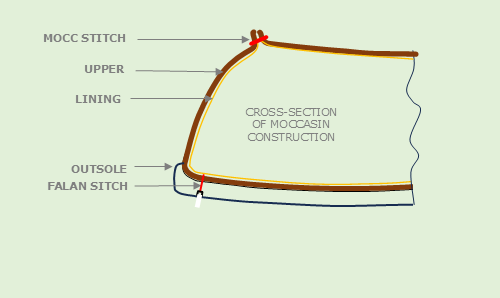

E. Moccasin Construction

- Upper leather wraps under the foot and stitched at the top

- Seen in Loafers, Driving Shoes

- Pros – Soft, Flexible, unique Look

F. Vulcanized Construction

- Canvas shoes, skate shoes (e.g., Converse)

- Rubber Outsole is bonded Via Heat + Pressure

- Pros – Classic Look, Durable Shoes

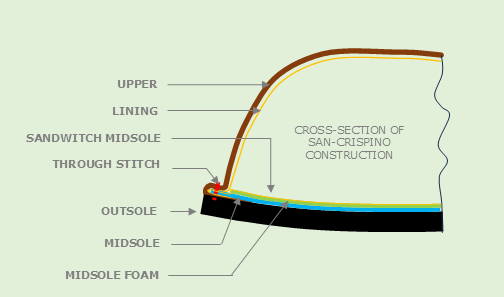

G. San Crispino Construction

- The upper is stitched directly to the insole from the outside

- No Strobel of Board – Gives Flexibiliy and Natural movement

- Pros – Light Weight & Flexible.

- Cons – Limited Durability

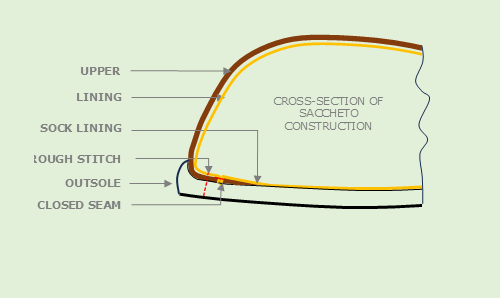

H. Sacchetto Construction

- A soft leather sock (sacchetto) is stitched to the upper inside out

- The shoe is then turned right-side-out (requires expert craftsmanship)

- Pros : Extremes Comfort, Glove Like Fit

- Cons : Time consuming, Costly

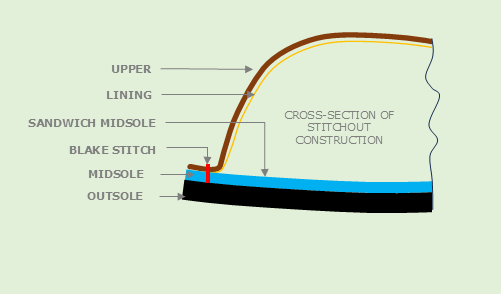

I. Stitch-down (Stitch-out) Construction

- Upper is turned outward and stitched to the midsole/outsole

- Creates a wide look, good for casual boots and work shoes

- Pros: Durable, Weather Resistant

- Cons: Heavier feel, Visible Stitching

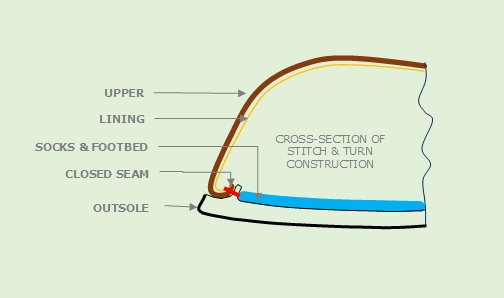

J. Stitch & Turn Construction

- In this method, the upper is stitched to the sole inside out, with the right side of the leather or fabric facing inward.

- After stitching, the entire shoe is turned right side out, so the seams are hidden inside and the exterior appears smooth and clean.

- Pros: Superior flexibility and comfort, Superior flexibility and comfort, Lightweight feel

- Cons: Limited support and structure, Not suitable for heavy-duty wear

“Though the constructions mentioned above form the foundation of shoemaking, modern technologies and innovations in footwear manufacturing allow brands to tweak and refine these methods. Within each category, there are numerous variations and hybrid methods developed. Today, the fit, comfort, performance, and even sustainability aspects of a shoe can be customized or enhanced based on the end-use, material innovations, or consumer needs.”