Shoe Materials Guide: Impact on Footwear Adhesive Performance

Introduction

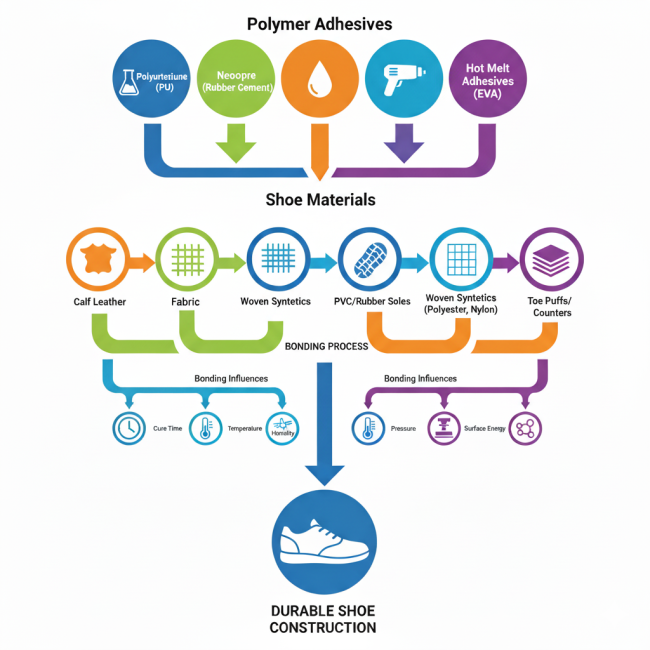

In our previous blog on polymer chemistry as the foundation of footwear adhesives, we examined how monomers and polymers create effective bonding agents. Now, we advance that discussion by focusing on shoe materials for adhesive bonding—the essential substrates that interact with those adhesives to form strong, lasting connections in shoes.

These materials, ranging from natural leathers to advanced synthetics, directly affect adhesion through their porosity, surface chemistry, and mechanical properties. For example, a porous leather might absorb adhesives deeply for mechanical locking, while a slick synthetic requires primers for chemical compatibility. In this expanded guide, we delve deeper into leather structures, synthetic uppers and soles, insoles, and reinforcements, highlighting their characteristics and bonding implications. Furthermore, this sets the stage for our next post on adhesive systems, where we’ll explore tailored formulations. Let’s begin!

Leather: Structures and Bonding Characteristics Across Types

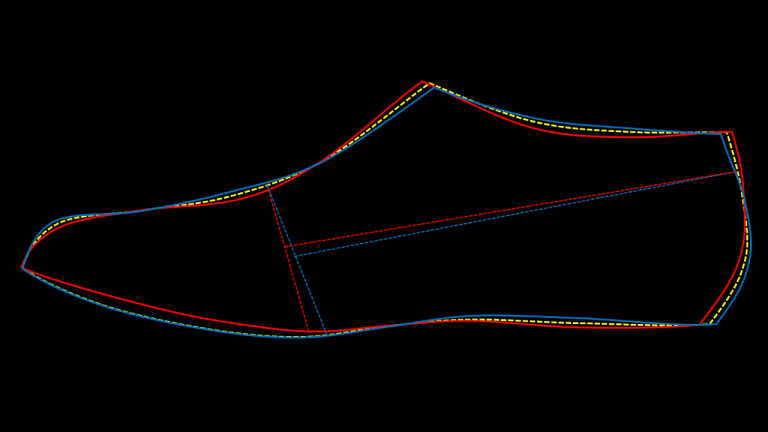

Leather serves as the traditional cornerstone for shoe construction, offering breathability, durability, and aesthetic appeal. Manufacturers derive it from various animal hides, each with distinct structures that influence adhesive bonding. We start with calf leather and expand to others, emphasizing how their fibrous makeup affects adhesion.

Calf leather originates from young cow or buffalo hides, typically chrome-tanned for flexibility. It spans 5 to 15 square feet per skin, featuring a close fibrous structure that spreads uniformly. Moreover, it exhibits minimal variation in collagen content, thickening slightly at the butt portion. The grain surface, formed by sweat glands and hair follicles, appears small and fine without a definite pattern—resulting in a subtle “break” when folded. Dye absorption remains uniform with few surface defects, yielding smooth, boarded, or suede finishes. For adhesive bonding, calf leather’s even porosity allows deep penetration, enhancing mechanical interlocking. However, its rubbery feel demands good physical testing properties, making it ideal for high-quality ladies’ and men’s shoes where strong, flexible bonds are crucial.

Hide leather, in contrast, comes from mature cattle hides (cow, ox, buffalo), split into two sides along the backbone and tanned via chrome, semi-chrome, or vegetable methods. Each side measures 14 to 30 square feet, providing a robust, consistent surface. Its structure supports even adhesive distribution, but the thicker grain may require roughening for optimal grip. Transitioning to kid skins, these derive from young goats, offering a light, fine grain with excellent dye absorption. Kid leather’s soft, warm feel suits ladies’ shoes, where its high-grade gold or silver finishes bond well with flexible adhesives to prevent cracking.

Goat skins produce high-grade leathers with small, smooth grain patterns, classified by finish like glazed or embossed. They absorb dyes evenly, making them suitable for uppers and linings. For bonding, goat leather’s natural oils can resist adhesives, necessitating degreasing primers. Sheep skins, meanwhile, yield soft, wool-like materials with coarse grain and loose fiber structure. They absorb dyes unevenly, leading to variable bonding—ideal for casual shoes but requiring moisture-resistant adhesives to combat hydrolysis.

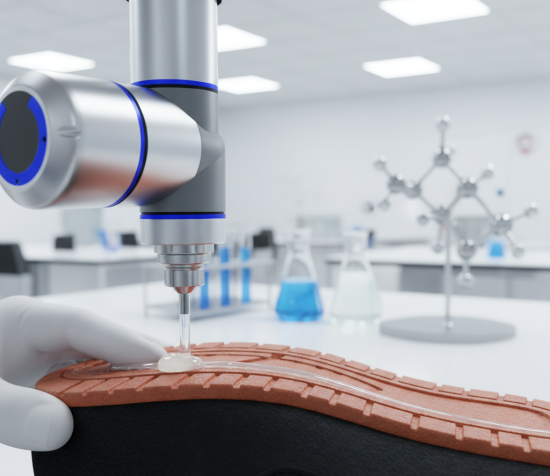

Finally, oily leathers incorporate additional fats for water resistance, common in work boots. Their impregnated surface reduces porosity, challenging adhesive wetting; however, solvent-based systems excel here by dissolving oils for better penetration. Overall, leather types demand adhesives that match their structures—porous for mechanical bonds, oiled for chemical compatibility. For deeper insights, explore types of shoe leather guides of linking monomers polymerization, and it occurs in various ways, shaping different polymer structures and properties. For example, this process underpins the adhesives that secure shoe soles.

Synthetic Uppers: Fabrics and Foams for Enhanced Bonding

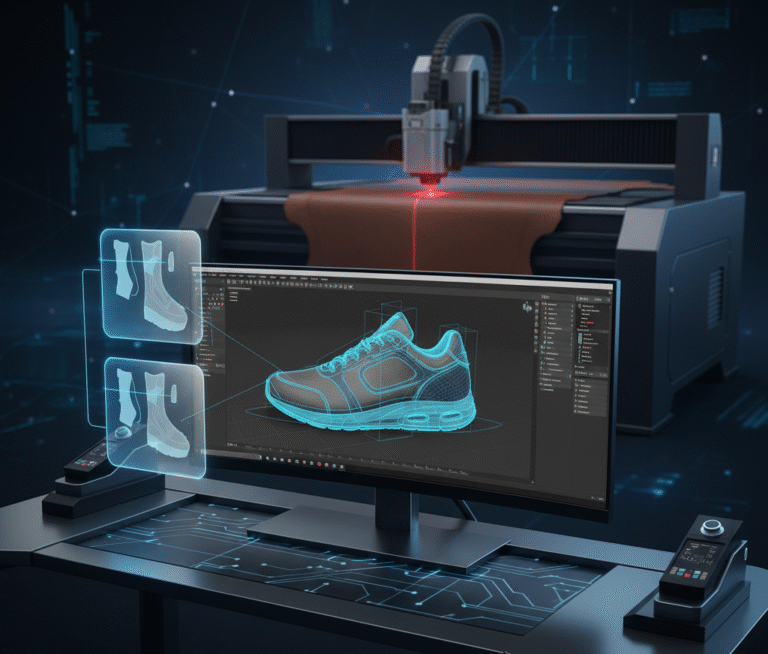

Synthetic uppers provide versatile, cost-effective alternatives to leather, often mimicking natural textures while offering superior weather resistance. We explore coated fabrics, woven, knitted, non-woven, polyurethane, and PU foam, focusing on their properties for adhesive bonding.

Coated fabrics feature a base textile layered with polymers like PVC or PU, creating water-repellent surfaces. For instance, polyurethane-coated fabrics resist abrasion and flexing, but their non-porous top layer requires etching or primers for adhesion. Woven fabrics, such as polyester or nylon weaves, interlace yarns for strength—think denim-like structures for durability. Their open weave promotes mechanical bonding as adhesives fill gaps, though high tension demands flexible glues to avoid cracking.

Knitted fabrics, in turn, stretch for comfort, using looped yarns that entangle with adhesives for secure holds. Non-woven fabrics, bonded without weaving (e.g., via heat or chemicals), offer lightweight uniformity—perfect for linings where even adhesive spread prevents lumps. Polyurethane (PU) uppers, lightweight and flexible, mimic leather but need isocyanate-based adhesives for chemical compatibility. PU foam, expanded for cushioning, absorbs adhesives into its cells, enhancing foam-to-upper bonds but risking compression under pressure.

These synthetics shine in athletic shoes, where PU foam’s resilience pairs with knitted uppers for breathable, bonded structures. However, low surface energy often calls for plasma treatments to boost wettability. In practice, water-based adhesives suit eco-friendly non-wovens, while hot-melts work for coated types. For more on synthetics, see polyurethane adhesives for textiles. understanding these categories guides manufacturers in choosing durable materials.

Synthetic Soles: Outsole Materials and Their Adhesive Interactions

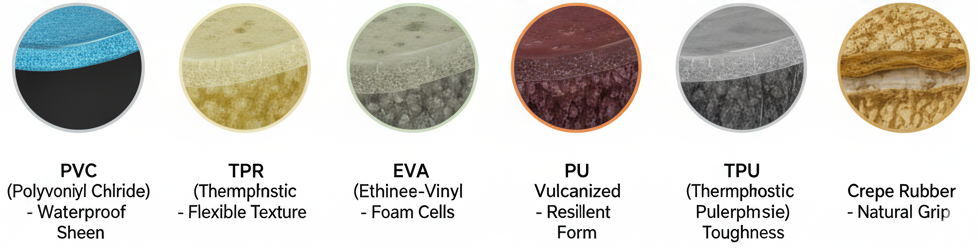

Synthetic soles dominate modern footwear for their grip, cushioning, and affordability. We detail PVC, TPR/TR, EVA, PU, vulcanized rubber, TPU, and other outsoles, explaining properties and bonding needs.

PVC (Polyvinyl Chloride) provides waterproof, durable soles with good abrasion resistance. However, its slick surface challenges bonding—solvent primers roughen it for mechanical adhesion. TPR (Thermoplastic Rubber) combines rubber’s elasticity with plastic’s processability, offering anti-slip traction. TPR bonds via heat activation, fusing to uppers without delamination.

TR (Thermoplastic Rubber variant) emphasizes flexibility, ideal for casual shoes; its SBS-modified structure grips adhesives well under flexing. EVA (Ethylene Vinyl Acetate) excels in lightweight midsoles, with foam cells absorbing impacts. Bonding requires pressure-sensitive adhesives to prevent foam collapse. PU (Polyurethane) soles deliver cushioning and resilience, chemically bonding with isocyanates for seamless integration.

Vulcanized rubber, cross-linked with sulfur, provides superior traction—common in outsoles where its porosity enhances mechanical locks. TPU (Thermoplastic Polyurethane) adds toughness, resisting oils; it bonds via fusion welding for high-performance boots. Other outsoles, like crepe rubber, offer natural grip but need vulcanization agents for adhesion.

These materials vary in density: EVA’s low weight suits running shoes, while PVC’s rigidity fits work boots. Adhesive selection hinges on compatibility—e.g., PU adhesives for TPU to match expansion rates. For details, reference TPR vs. PVC comparisons.

Insoles: Supportive Layers and Bonding Essentials

Insoles form the footbed, influencing comfort and stability. We cover non-woven, cellulose, and fibre board types, detailing their traits for adhesive bonding.

Non-woven insoles, made from bonded fibers (e.g., polyester), offer breathability and flexibility. Their uniform structure ensures even adhesive distribution, ideal for Strobel stitching where glues secure edges without bunching. Cellulose boards, derived from wood pulp, provide moisture-resistant rigidity—suitable for board lasting. They absorb adhesives deeply for strong mechanical bonds but swell with humidity, requiring water-based formulas.

Fibre boards, compressed from recycled fibers, balance cost and durability. Their dense makeup resists tearing, bonding via latex adhesives for welted constructions. Characteristics like hardness and elasticity vary: non-wovens flex for athletic shoes, while cellulose stiffens dress footwear.

Bonding challenges include porosity—non-wovens wick adhesives quickly, risking over-penetration, so controlled application prevents weakening. These insoles often laminate with foams, where heat activation fuses layers. For sustainable options, see Texon insole materials.

Reinforcements: Enhancing Structure Through Fabrics and Foams

Reinforcements bolster shoe integrity, from toe puffs to stiffeners. We examine fabrics, coated/sticker types, linings, toe puffs, stiffeners, fillers, EVA foam, and PU foam, with bonding insights.

Fabrics, often non-woven or woven, reinforce vamps—self-adhesive versions peel and stick for easy bonding. Coated fabrics add water resistance, using thermoplastic adhesives for fusion. Sticker types, pre-coated with glue, simplify assembly via heat press.

Linings, like knitted or PU-coated, provide comfort; they bond to uppers with latex for breathability. Toe puffs, thermoplastic sheets (e.g., EVA-based), mold under heat (80°-120°C) to shape toes—adhering via moisture-curing urethanes. Stiffeners reinforce heels, using fibre or PU materials that activate with pressure for rigid bonds.

Fillers, such as EVA or PU foam, cushion voids; EVA’s closed cells resist compression, bonding with contact adhesives. PU foam expands for gap-filling, chemically linking with isocyanates. These components prevent flex failures, with adhesives matching expansion rates.

In summary, reinforcements demand precise bonding—e.g., hot-melts for toe puffs to avoid distortion.

Conclusion

Understanding shoe materials for adhesive bonding unlocks superior footwear design, where leather’s porosity meets synthetic soles’ resilience. From calf leather’s uniform structure to EVA insoles’ cushioning, each element shapes bonding success. Moreover, reinforcements like PU foam ensure structural integrity. As we conclude, these insights prepare us for our next blog on adhesive systems, detailing formulations that optimize these interactions. Share your thoughts below!

Subscribe for ongoing footwear manufacturing tips.