Precision in Shoemaking: Understanding Shoe Last Specification Sheets and Profile Checking Templates

In the intricate world of footwear manufacturing, the shoe last serves as the blueprint for every pair of shoes, influencing fit, comfort, and style. As the foundation of precision shoemaking, shoe last specification sheets and profile checking templates ensure that every dimension and curve aligns perfectly with design intentions. Drawing from real-world examples like detailed last spec sheets, this guide delves into their components, importance, and practical applications. Whether you’re a footwear designer, manufacturer, or enthusiast exploring shoe last design, mastering these tools is essential for achieving consistent quality and performance in footwear production.

The Importance of Shoe Last Specification Sheets and Profile Checking Templates

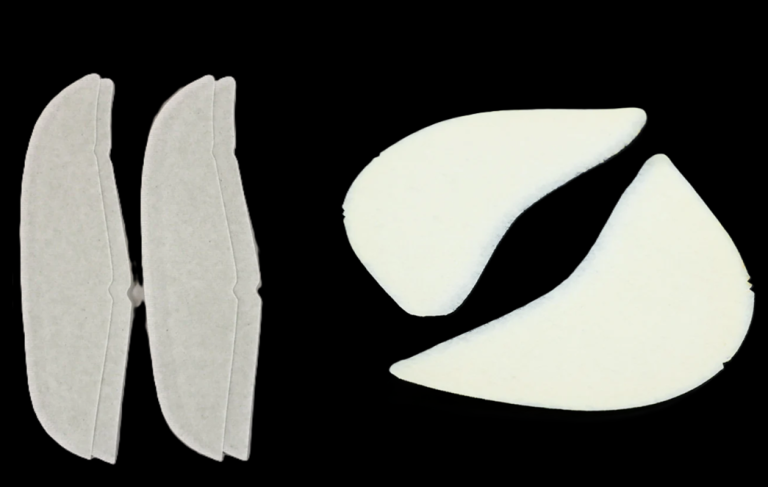

Complementing these sheets are profile checking templates and gauges—tools used to verify the physical last against the specified dimensions. These ensure accuracy down to millimeters, which is critical in performance footwear where even minor deviations can affect comfort, stability, and durability. Together, they promote repeatability in shoemaking, reduce material waste, and uphold brand consistency in competitive markets like athletic, casual, and formal footwear manufacturing.

In practice, a typical last spec sheet includes header details such as Shoe Group Name, Season, Brand, Last Factory, Shoe Construction, Gender & Size Range, Last #, Date, Sizing System, and Shoe Factory. These provide context for the last’s application. The core lies in a detailed table of measurements and profiles, often accompanied by remarks, special instructions, and revision tracking for quality control.

Breaking Down Key Components: Explaining Each Description in a Shoe Last Specification Sheet

To illustrate, let’s examine the key descriptions from a standard shoe last specification sheet. Each element contributes to the last’s overall geometry, ensuring the shoe molds perfectly to the foot while accommodating various styles and constructions.

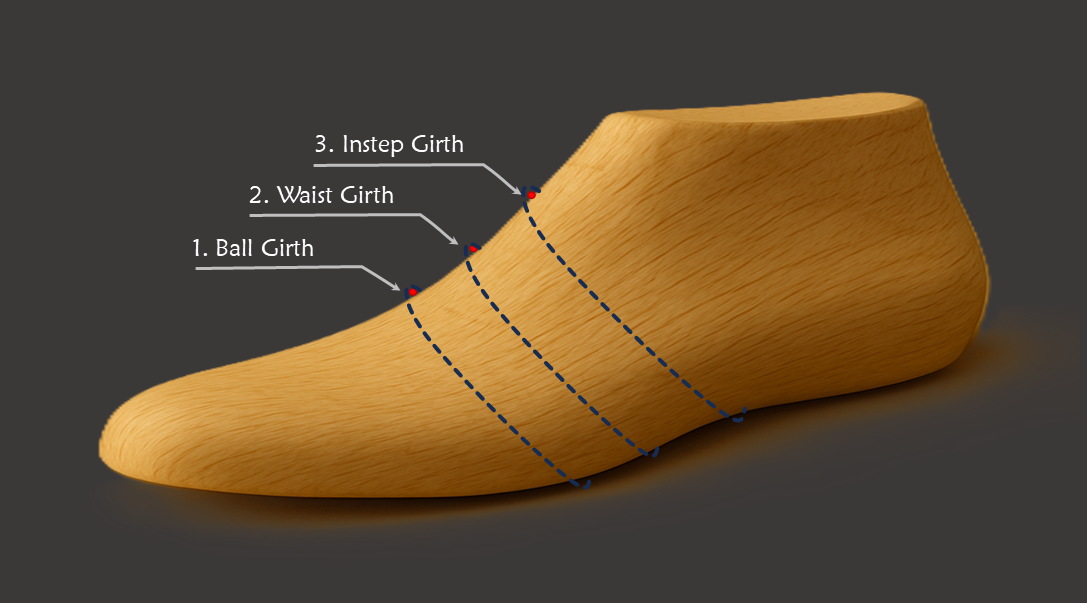

1. Ball Girth (mm): This measures the circumference around the widest part of the forefoot, typically at the ball joint. It’s crucial for shoe fit consistency, as it determines how snugly the shoe hugs the foot’s broadest area, preventing slippage or pressure points in performance footwear.

2. Waist Girth (mm): Refers to the circumference at the narrowest midfoot section. This dimension ensures arch support and stability, vital for footwear last dimensions that balance comfort with structure, especially in boots or sneakers where midfoot lockdown is key.

3. Instep Girth (mm): The measurement around the highest part of the foot’s arch. It influences the shoe’s volume over the instep, affecting ease of entry and overall fit—essential for accommodating different foot shapes in size ranges like men’s, women’s, or unisex.

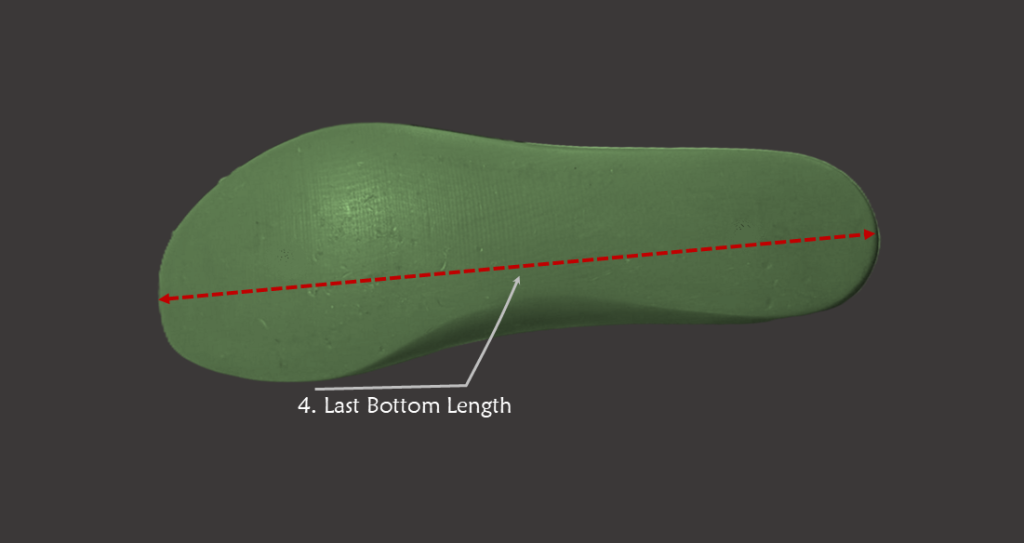

4. Last Bottom Length (mm): The length from the heel to the toe along the sole plane. This foundational metric scales the entire shoe last model, ensuring proportional sizing across gender and size ranges for accurate outsole bonding and alignment.

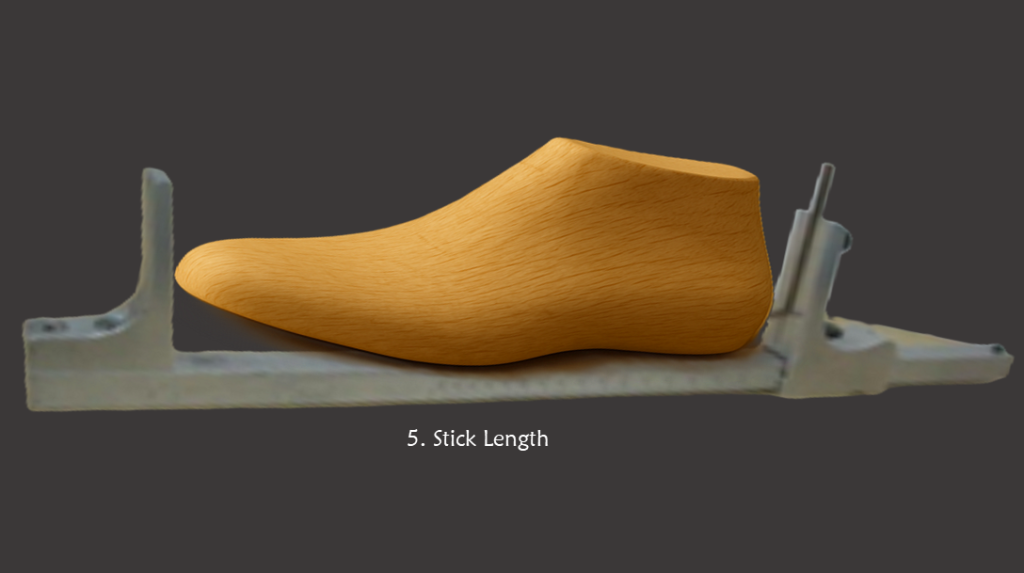

5. Stick Length (mm): Measured along the top surface of the last from heel to toe. It differs slightly from bottom length due to curves.

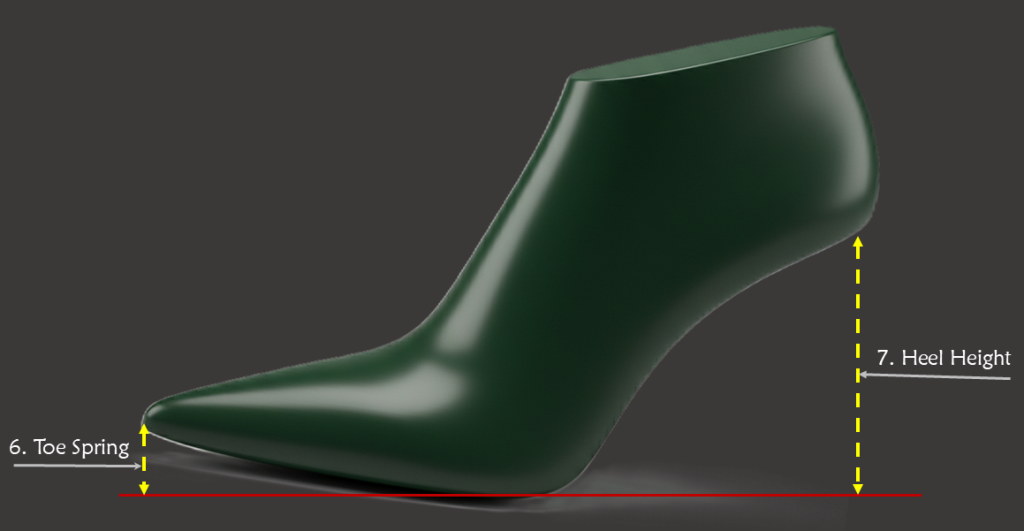

6. Toe Spring (mm): The vertical rise at the toe end, creating a slight upward curve. This enhances toe-off during walking, improving comfort and reducing fatigue—particularly important in athletic footwear for natural gait support.

7. Heel Height (mm): The elevation at the heel, dictating the shoe’s pitch and posture. It impacts balance and style, from flat casual shoes to heeled dress options, ensuring ergonomic precision in shoemaking.

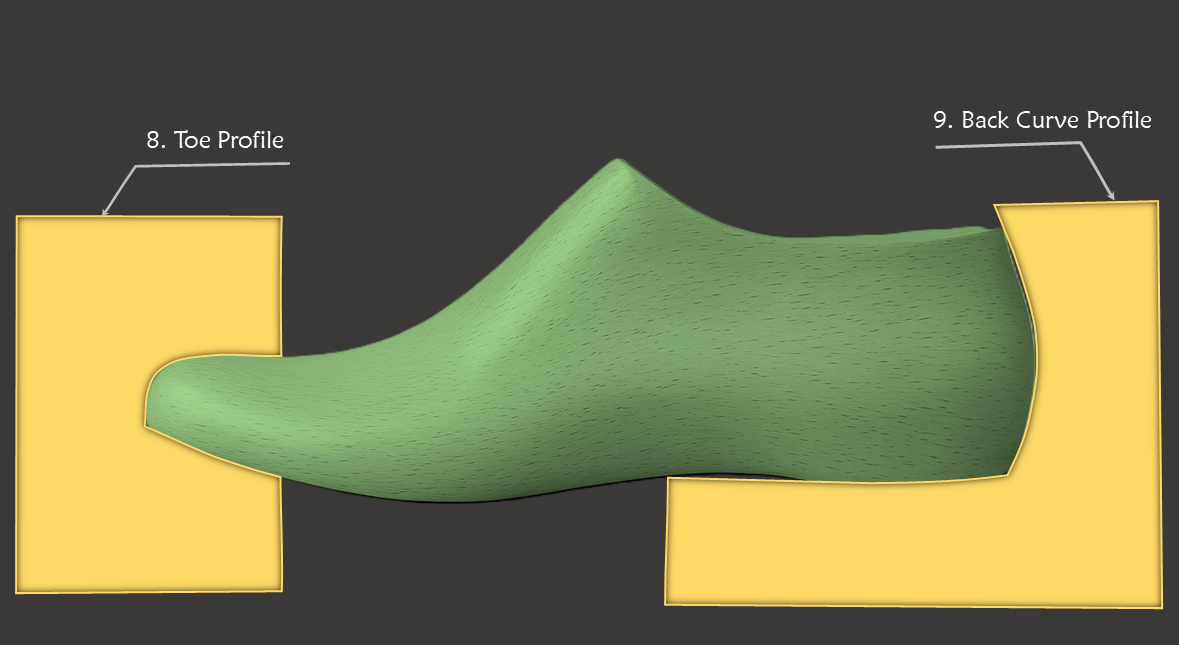

8. Toe Profile (Profile Pattern): A template-based check for the toe’s shape and thickness. Using profile checking templates, this verifies the toe box’s contour, ensuring aesthetic appeal and room for toes without excess bulk

9. Back Curve Profile (Profile Pattern): Assesses the curvature along the heel’s back. This profile ensures a secure heel fit, preventing blisters and enhancing rearfoot stability through precise profile checking gauges.

10. Cuboid Profile (Profile Pattern): Focuses on the Medial & lateral midfoot area near the cuboid bone.

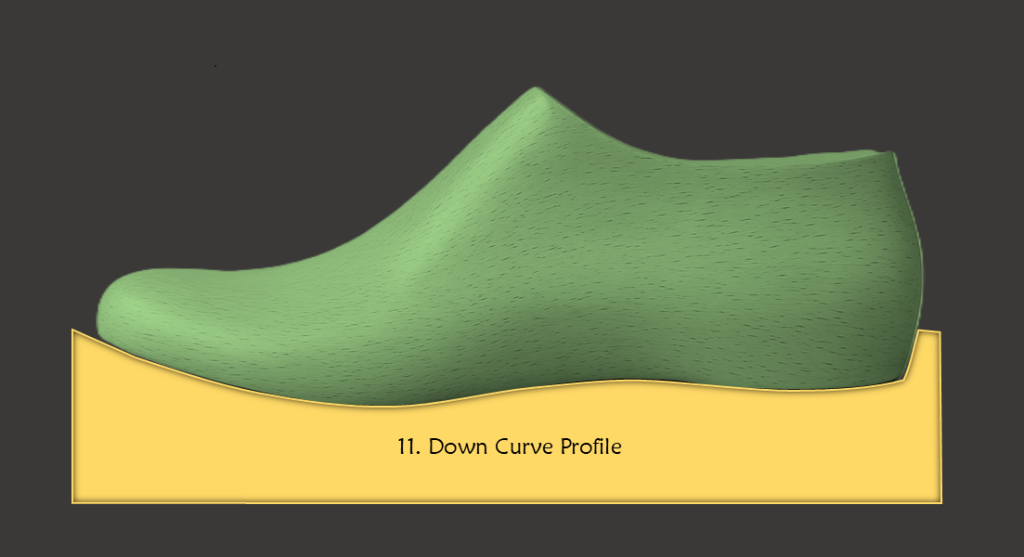

11. Down Curve Profile (Profile Pattern): Examines the downward slope from Toe to heel. Critical for smooth transitions, this profile aids in comfort during movement, verified via last profile templates.

12. Forepart Bottom Radius (Profile Pattern): The curved radius at the forefoot base. It ensures even pressure distribution and flexibility, key for shoe last design in dynamic activities.

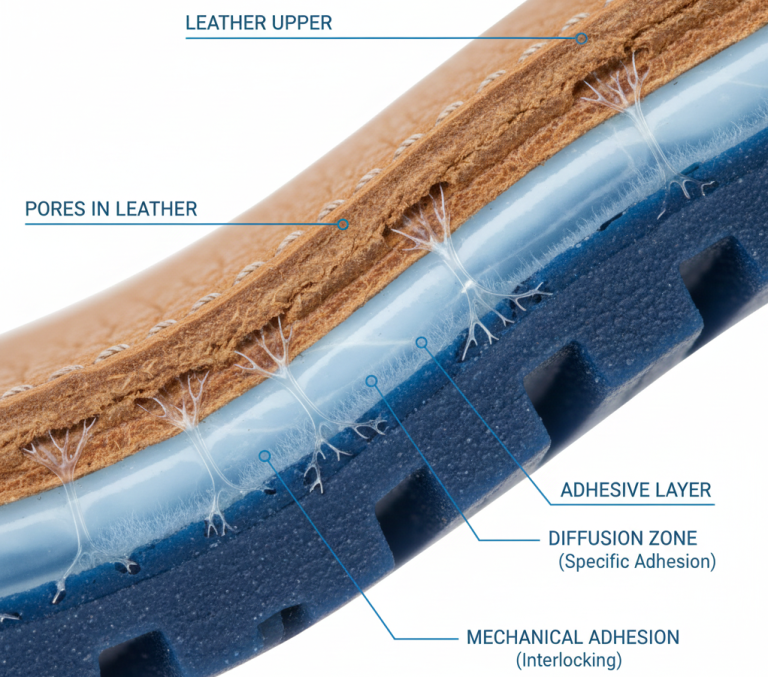

13. Heel Bottom Radius (Profile Pattern): The heel base’s curvature, promoting to align heel foot for better comfort and stability. Templates here confirm compatibility with outsoles for durable bonding.

14. Backpart Base: Foundation of any new last. Normally, backpart is standardised based on the Construction, Heel height and End Use.

Beyond these, special instructions might include material notes, tolerance variances (e.g., ±1 mm), or custom adjustments, while revision history tracks changes for accountability. Profile checking templates—physical patterns or digital scans—are applied to each, often using tools like Vernier calipers or 3D CAD comparisons for verification.

The Broader Impact on Footwear Manufacturing

Integrating these detailed specifications with profile checking tools streamlines footwear manufacturing processes, from prototyping to mass production. They minimize defects, enhance production efficiency, and support scalability across global supply chains.

Conclusion: Elevating Standards in Precision Shoemaking

In summary, shoe last specification sheets and profile checking templates are indispensable for achieving excellence in footwear design and production. By meticulously defining and verifying elements like girths, lengths, and profiles, they ensure every shoe delivers on fit, function, and form. For footwear manufacturers aiming for innovation and reliability, investing in these tools is a step toward superior precision shoemaking and lasting brand success.

For a deeper understanding of shoe lasts, explore our related posts: Shoe Lasts Explained: Their Role in Footwear Design , Beyond the Last’s Surface: A Deep Dive into Hinges, Plates, and Technical Features

Share your thoughts or questions in the comments