Comprehensive Guide to Sewing Machine Needles: Full Technical Reference

Parts, Manufacturing, Points, Stitch Appearance, Perforation Effects – Especially for Leather

Estimated Reading Time: ~ 5 – 6 minutes

Introduction

Sewing machine needles are the critical link that carries the thread through the material, forms the stitch, minimizes friction and thread damage, and strongly influences seam appearance through the perforation shape created by the point. Correct selection prevents skipped stitches, thread breakage, material tearing, and weak seams—particularly important for leather, synthetics, coated fabrics, and heavy materials.

Function of the Needle

The needle takes the thread through the material being sewn with minimal friction and damage, helps form the stitch, and at the same time impacts the appearance of the stitching by the shape of the puncture made by the point.

Manufacturing

Needles are made by die-pressed cold forging using tough high-carbon steel. The pressings are polished and finally coated. Popular coatings are nickel or chromium, providing hard, smooth surfaces that resist frictional heat during sewing.

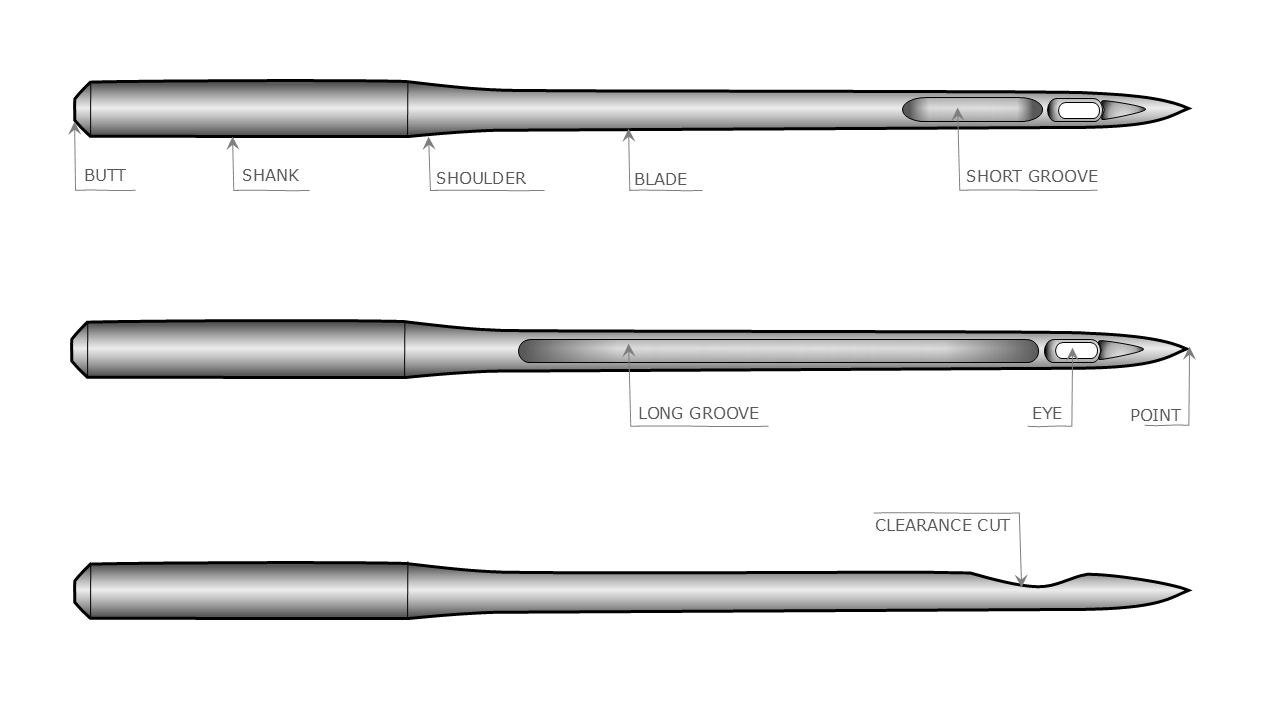

Features and Parts of the Needle

- Butt: Slightly tapered or rounded end for easy entry into the needle bar.

- Shank: Thickest part, fits into the needle bar and held by screw; classified by length, diameter, shape per machine class.

- Shoulder: Gradation from shank to blade, gives strength to the blade.

- Blade (Shaft): Passes through material; has long groove (front) to guide/protect thread and reduce heat, short groove (back) to form thread loop for stitch formation.

- Long Groove: Protects thread as it passes through material.

- Short Groove: Assists loop formation as needle rises/withdraws.

- Eye: Passage for thread; size must match thread to avoid friction/slip-stitching.

- Point: Penetrates material, forms hole; shape determines thread path, material damage, and seam appearance.

- Scarf (Clearance Cut): Cut above eye allowing hook/shuttle close approach for loop pickup; also called “scarf”.

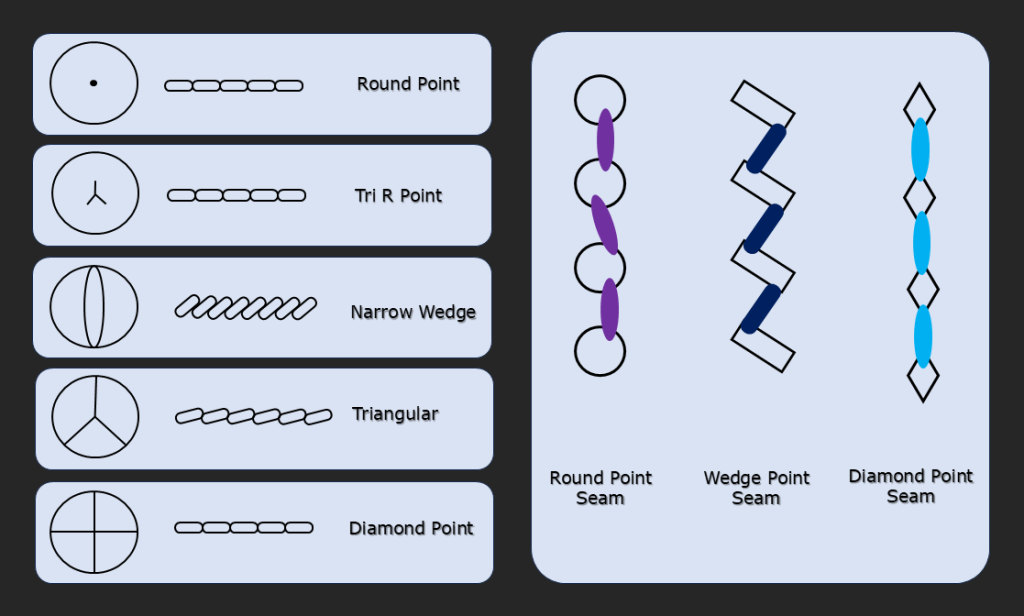

Identification of Needle Points

Draw a thin straight line on paper (representing threading direction). Position needle so long groove aligns with line (usually left-to-right on single-groove needles when flat-bed mounted). Pierce paper with point; examine hole pattern to identify point type (slant, cross, diamond, etc.). Common styles: 134-35, 134-S, 34-LR, 34-LL, 34-P, 34-PCL, 134-D, 134-DI, 134-LR, 134-P, etc. Most used: 134-35, 134-S.

Needle Points and Characteristics of Seams

- LR (Reverse Twist / Left Twist): Reverse twist point; transversal stitches, almost complete hole cutting; light flat seam. Suited for common leather grades, slanting stitch position.

- LI / LL (Twist / Left Twist): Twist point; light flat seam, stitches almost straight, cutting almost complete hole.

- P (Wedge): Wedge point; protruding transversal bead seam, cuts and widens hole for short stitches; well-protruding seam with little cutting (mainly widening); good for patent leathers.

- PCR (Narrow Wedge, Right Twist Groove): Narrow wedge, right twist; well-protruding bead seam with transversal stitches; for hard-grained/tough leathers.

- PCI (Narrow Wedge, Left Twist Groove): Similar to PCR but left twist.

- S (Cross Point): Cross point; light flat seam, almost complete hole cutting for long stitches.

- DI / DIA (Diamond Point): Diamond point; light flat seam, cutting almost complete hole for long stitches; deeply set seams on heavy leathers.

- D / TRI (Triangular Point): Triangular point; light flat seam, cuts hole almost completely on three sides; well-set straight stitches on heavy/dry leathers.

- R (Ball / Round Point): Rounded; for synthetics, cloth, canvas, knits, elastics; pushes fibers apart (no cutting).

Round vs Cutting Points – Detailed Comparison

- Round / Cloth Point: Mainly for fabrics; pushes fibers apart (no cut); straight stitch on non-wovens but high dome on dense materials; reduces friction with small triangular tip variants for coated/imitation leathers.

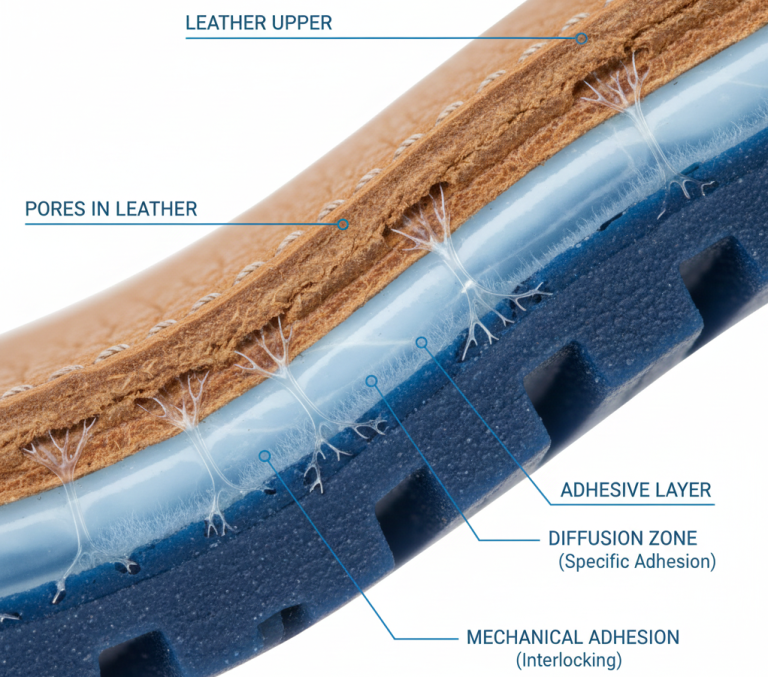

- Cutting Points (reduce friction on dense/thick materials like leather):

- Triangular-Round (TriR): Small triangular cutting tip on round body; overcomes issues in dense synthetics/new coated fabrics.

- Narrow Wedge: Right-angle cut to stitching line; very even, raised stitch; ideal for high stitch density on leather (fine decorative work).

- Triangular: Good cutting on thick/heavy materials; slightly diagonal, even but flat stitches.

- Diamond: For very thick/dry materials; flat, well-bedded stitches; risk of splitting if stitches too short/close.

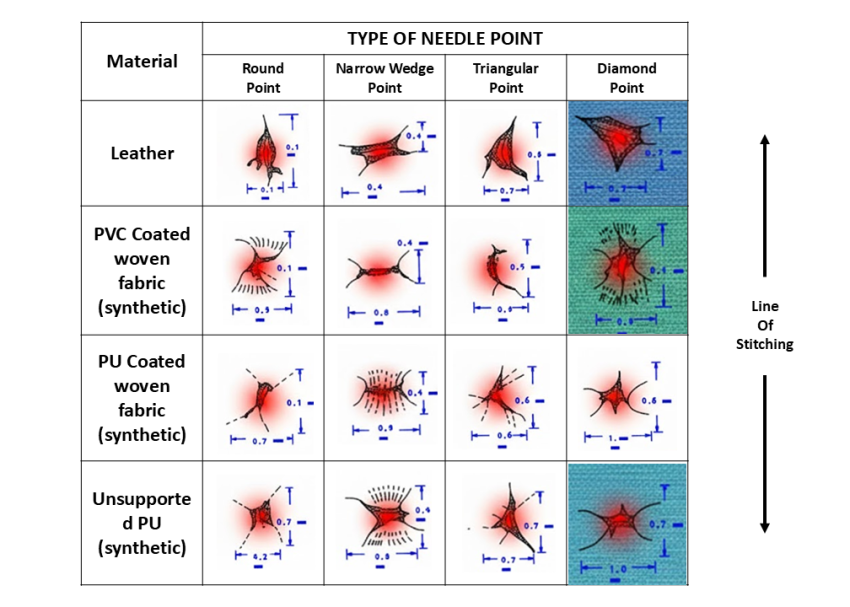

Stitch Appearance & Perforation Effects

(After sewing, thread removed, material recovered for several hours) Perforation shape follows point shape. Cutting points cause much larger permanent damage in leather than round points. Synthetics show more recovery/bearing but still greater damage from cutting points.

- Round point seam: Slightly domed, even.

- Wedge point seam: Raised, prominent bead/string-of-pearls.

- Diamond point seam: Flat, deeply recessed, straight (longer stitches needed).

Shuttle & Feed Types

- Shuttle/Hook: Oscillating (arc) or Rotary (circular/hook).

- Feed: Rotary (needle out), Stop (needle out), Walking/Unison (needle in work).

Conclusion

Needle damage weakens tensile strength—it is unavoidable for functional/economic/style seams but can be minimized by correct thread, needle point, and stitch length choice. Machine seams cannot be 100% waterproof in wear (despite salesperson claims), though steps reduce water penetration. Always test, use fresh needles, match point to material (round for recovery/fabrics, cutting for leather).

Top 5 Leading Sewing Machine Needle Suppliers Worldwide

For sourcing high-quality needles—especially for industrial and leather applications—consider these globally recognized leaders. They offer reliable precision, durability, and a wide range of point types (including LR, TRI, and DIA variants):

- Groz-Beckert (Germany) The world’s leading supplier of industrial machine needles, known for high-precision products in apparel, automotive, and technical textiles. Website: https://www.groz-beckert.com

- Schmetz (Germany) Established in 1851, specializing in household and industrial needles with strict quality standards—ideal for universal, leather, and specialty points. Website: https://www.schmetz.com

- Organ Needle (Japan) A major Asian producer of industrial needles, renowned for ball-point, universal, and durable types with global subsidiaries. Website: https://www.organ-needles.com

- Singer (US) Iconic brand offering a broad range of household and industrial needles, with widespread distribution and manufacturing in various regions. Website: https://www.singer.com

- Nantong Zhongde Making Needle Co., Ltd. (China) A prominent Chinese exporter specializing in industrial and household needles (e.g., DBx1, DPx5 systems), known for high-volume supply and quality certifications. Website: https://zdneedle.en.alibaba.com

Other notable mentions include Dotec Needle (Taiwan) and various Chinese manufacturers contributing to global production dominance.