Footwear Stitching Threads Guide: Thread Construction, Stitch Performance & Needle Interaction

Estimated Reading Time: ~ 9 minutes

Introduction: Beyond Thread Selection

In Part 1 of this series, we explored footwear stitching threads from a selection and application perspective—covering thread materials, twist directions, numbering systems, suppliers, and SATRA standards.

However, selecting the right thread alone does not guarantee seam quality.

In real factory conditions, stitching performance is defined by how the thread behaves inside the sewing machine—how it twists, how it passes through the needle, how it forms loops, and how the stitch finally locks inside the material.

This Part 2 guide focuses on the engineering side of footwear stitching, explaining the technical factors that determine seam durability, stitch consistency, and long-term wear performance.

Why Thread Construction Matters in Footwear Stitching

Two threads with the same material and size can perform very differently depending on how they are constructed. Thread construction directly influences:

- Tensile strength

- Abrasion resistance

- Stitch appearance

- Sewability at high speed

Understanding construction is essential for technicians, quality engineers, and line supervisors.

Types of Thread Construction Used in Footwear

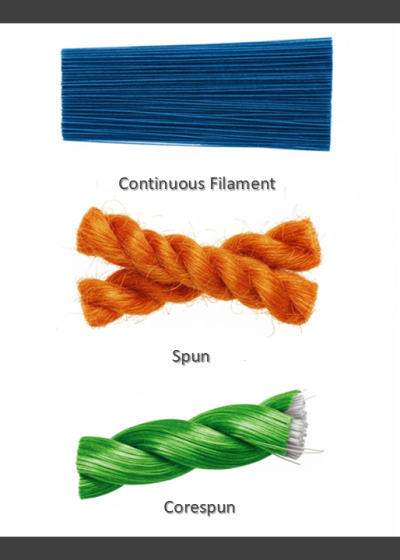

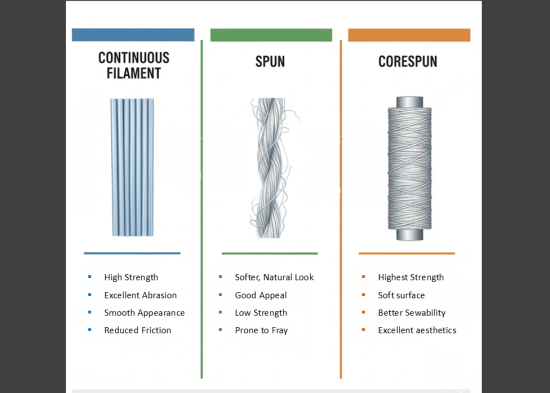

Continuous Filament Threads

Continuous filament (CF) threads are made from long, unbroken synthetic filaments, typically polyester or nylon.

Key characteristics

- Very high strength-to-diameter ratio

- Excellent abrasion resistance

- Smooth, uniform surface

- Often coated with a thin polymer layer to reduce friction

Footwear applications

- Upper stitching

- Structural seams

- High-speed industrial sewing

CF threads are widely used where strength and consistency are more important than a soft or natural appearance.

Spun (Staple Fibre) Threads

Spun threads are produced from short fibres twisted together. These fibres may be cotton, linen, or polyester staple

Key characteristics

- Softer, more textile-like appearance

- Slightly “hairy” surface

- Lower tensile strength than filament threads

- More sensitive to abrasion and high sewing speeds

Footwear applications

- Decorative stitching

- Heritage or craft-style footwear

- Low-speed or hand-guided operations

Because of their lower strength, spun threads are rarely used for structural upper seams in modern mass production.

Corespun Threads

Corespun threads combine a continuous filament core with a spun fibre outer wrap.

Key characteristics

- Strength provided by the filament core

- Soft, natural appearance from the spun cover

- Improved sewability

- Balanced performance

Footwear applications

- Premium uppers

- Visible stitching where appearance and durability are both critical

Corespun threads are often considered the most versatile option for high-quality footwear uppers..

Thread Twist: Stability vs. Liveliness

Almost all footwear stitching threads are twisted constructions, where two or more yarns are twisted together.

Why twist is critical

Thread twist affects:

- Seam strength

- Resistance to fraying

- Loop stability during stitch formation

- Stitch line appearance

Twist-related problems

- Too little twist

- Thread may split, fray, or break

- Too much twist

- Thread may kink, loop, or snarl

This unstable behaviour is known as twist liveliness and is a frequent cause of sewing defects, especially at high speeds.

Machine compatibility

Most industrial lockstitch machines are designed to work with Z-twist threads.

Using the wrong twist direction can result in skipped stitches, inconsistent tension, and poor seam balance.

Stitch Density and Seam Strength

Seam performance depends not only on thread strength but also on stitch density—the number of stitches per inch or centimetre.

- High stitch density

- Increases seam strength

- Can weaken leather due to excessive perforation

- Low stitch density

- Preserves material integrity

- May allow seam opening under stress

The correct stitch density depends on:

- Leather thickness

- Upper material type

- Intended use of the footwear

There is no universal setting—each construction requires optimisation.

Needle and Thread Compatibility

Incorrect needle selection is a major cause of thread failure.

Best practice rule

The needle eye must be slightly larger than the thread diameter.

- Needle too small → excessive friction, heat buildup, early breakage

- Needle too large → visible stitch holes, poor appearance

Correct needle–thread matching improves:

- Stitch consistency

- Thread life

- Seam appearance

This becomes especially critical when sewing coated or bonded threads at high speed.

Stitch Formation in Lockstitch Machines

Most footwear uppers are sewn using lockstitch machines, where stitch formation relies on the rotary hook mechanism.

How the stitch forms

- The needle penetrates the material carrying the top thread

- As the needle rises, a loop forms behind it

- The rotary hook catches this loop

- The loop passes around the bobbin thread

- Both threads tighten, forming a locked stitch

Importance of thread tension

For a strong and clean seam:

- The stitch lock must sit inside the material

- Top and bottom thread tensions must be balanced

Incorrect tension can cause:

- Surface locking

- Reduced seam strength

- Poor visual quality

Performance-Based Thread Selection

When selecting threads for footwear production, always consider:

- Thread construction, not just material

- Machine type and speed

- Stitch density requirements

- Needle compatibility

- Visual expectations

In modern footwear factories, polyester continuous filament and corespun threads offer the most reliable balance of strength, appearance, and production efficiency.

Conclusion: Completing the Stitching Picture

Part 1 of this series focused on choosing the right thread.

Part 2 completes the picture by explaining how stitching actually works.

By understanding:

- Thread construction

- Twist behaviour

- Stitch density

- Needle and machine interaction

Footwear professionals can move beyond trial-and-error and achieve consistent, durable, and high-quality seams—from prototype to mass production.