Footwear Manufacturing Insights – Vamp Lining Design and Spring Adjustment Techniques

Reading Time : 3 Minutes

In footwear pattern engineering, vamp lining design and spring adjustment of pattern parts are closely related processes. Both aim to improve fit, comfort, and shape control without altering the fundamental balance of the pattern. This combined insight focuses on how controlled pattern modifications support efficient and repeatable manufacturing.

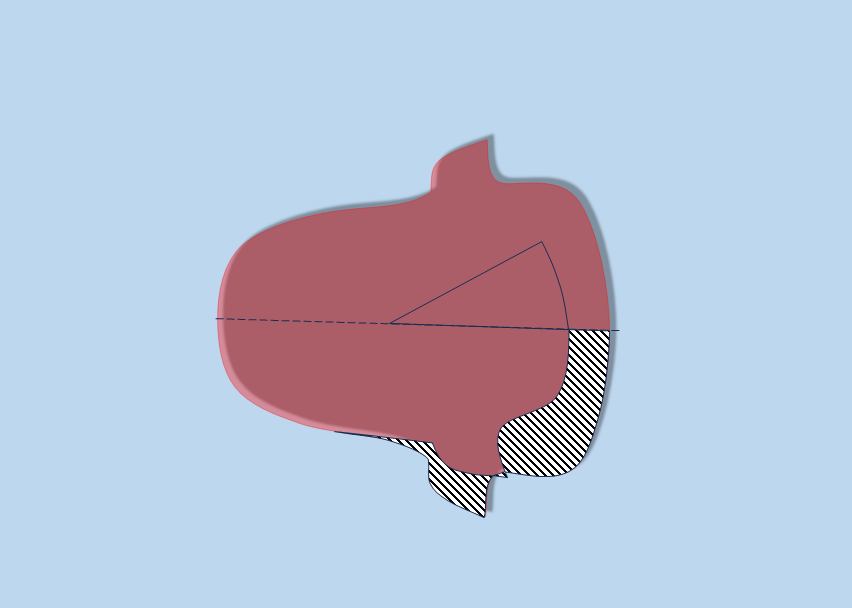

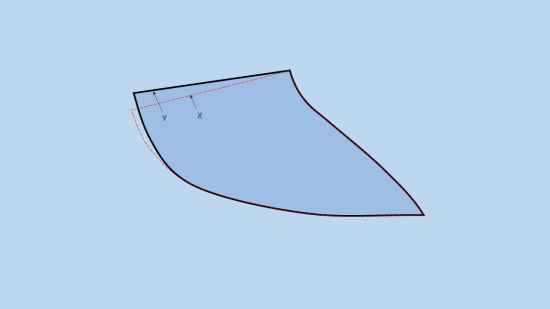

Vamp Lining Design: Fold Line Control

When a heavy-substance vamp lining is used, correct fold-line positioning becomes critical. The lining fits better when its fold line is positioned slightly lower at the toe compared to the standard upper pattern.

- The adjusted fold line allows the lining to follow the last shape more naturally.

- Sideways conformity across the upper is improved, reducing internal stress.

- The risk of wrinkles and pressure points during lasting is minimized.

From a pattern perspective:

- Fold Line X represents the lining fold line.

- Fold Line Y represents the standard upper fold line.

- A controlled offset between X and Y improves overall lining behavior.

A zig-zag (whipped) seam is commonly applied in this area to maintain flexibility while preserving seam strength during deformation.

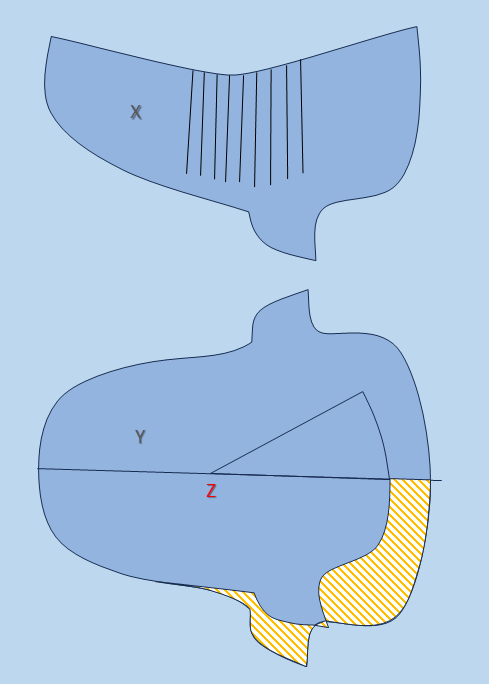

Spring Adjustment of Pattern Parts

In boots and extended Plug designs, it is often necessary to modify the spring of plug or vamp section without shifting the centre reference.

This is achieved by:

- Making parallel incisions in the middle section of the pattern (X)

- Gently opening the incisions to increase length or curvature (Y)

- Keeping Point Z (centre point) unchanged to maintain symmetry and balance.

Pattern interpretation:

- The sectional pattern with incisions shows where controlled expansion occurs.

- The finished template illustrates the final spring after adjustment.

- The hatched area represents the effective extension created by the process.

Manufacturing Value

By combining proper vamp lining fold-line control with precise spring adjustment techniques, footwear manufacturers can:

- Achieve consistent fit in structured uppers and boots

- Reduce pattern redevelopment time

- Improve repeatability during sampling and bulk production

Posts you may like

Conclusion

Vamp lining design and spring adjustment are not isolated tasks. When applied together, these techniques allow pattern makers to fine-tune shape, comfort, and manufacturability using small, controlled changes—resulting in better footwear with fewer corrections during development.