Footwear Manufacturing – Cutting Control Series : A Structured Guide to Leather Measurement, Costing, Grading & Cutting Performance

Estimated Reading Time: ~ 5 minutes

Introduction to the Cutting Control Series

Leather cutting is one of the most cost‑sensitive and technically demanding stages in footwear manufacturing. Small inefficiencies in leather measurement, grading, or cutting control can lead to significant material loss, cost escalation, and inconsistent production performance.

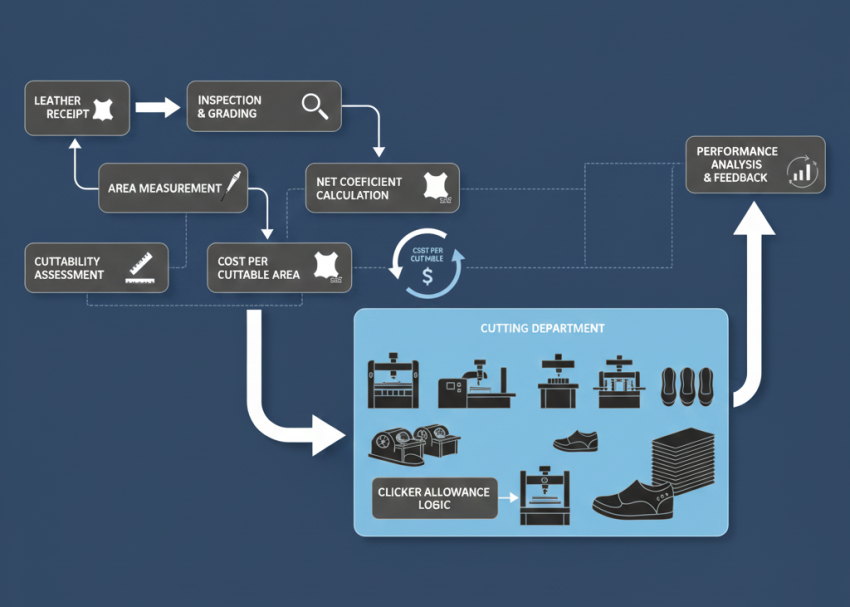

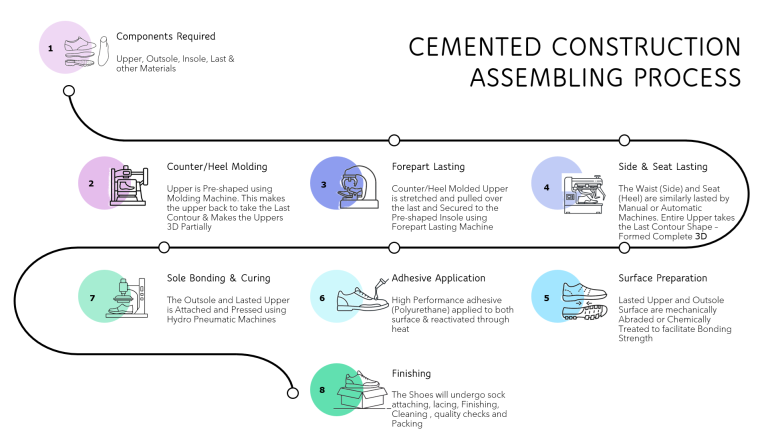

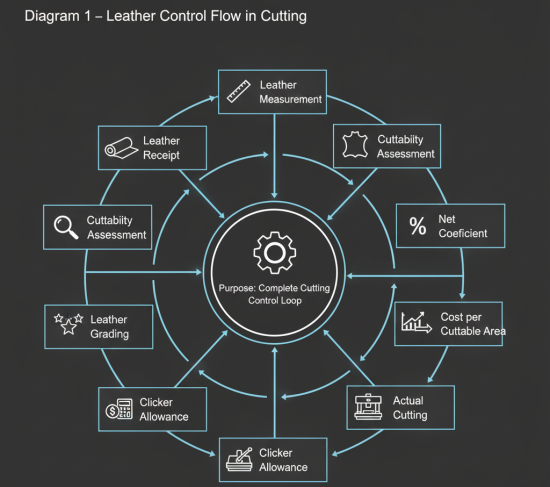

This Footwear Manufacturing – Cutting Control Series has been developed as a step‑by‑step technical guide . The series follows the natural flow of material control in a footwear factory — starting from leather receipt and inspection, moving through costing and grading, and finally arriving at cutting standards and performance evaluation.

Each article builds on the previous one, forming a closed‑loop cutting control system that can be directly applied in real factory environments.

Series Overview & Navigation

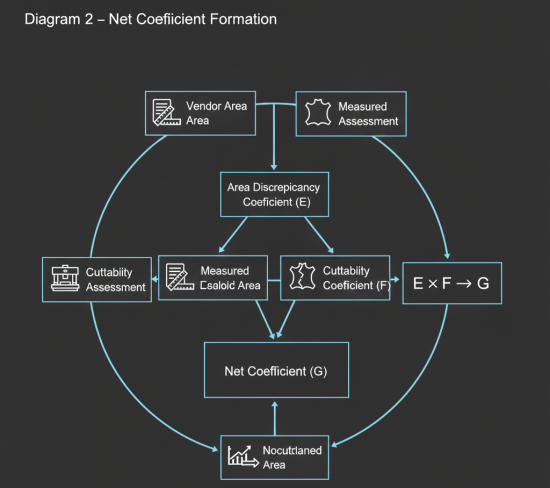

1. Leather Area Measurement, Discrepancy & Net Coefficient

Purpose: Establish factual leather quality data at incoming inspection.

Key Topics:

- Area discrepancy measurement

- Cuttability assessment

- Net coefficient calculation

Why It Matters: Creates the quantitative foundation for leather costing and cutting control.

2. Calculating True Leather Cost Using Cuttable Area

Purpose: Convert purchase price into real material cost.

Key Topics:

- Cost per cuttable square foot

- Standard cost setting

- Purchase cost variance analysis

Why It Matters: Enables objective vendor comparison and cost control.

3. Leather Grading Systems & Vendor vs Factory Sorting

Purpose: Align leather grading with factory cutting performance.

Key Topics:

- Vendor grading limitations

- Factory re‑sorting practices

- Grading linked to net coefficient

Why It Matters: Prevents waste caused by mismatch between vendor grading and factory needs.

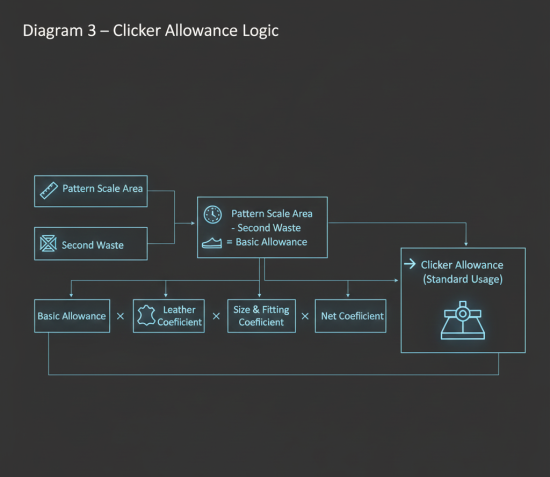

4. Clicker Allowance & Pattern Scale Area Calculation

Purpose: Establish scientific cutting standards.

Key Topics:

- Pattern scale area measurement

- First and second waste

- Size, fitting, leather type adjustments

Why It Matters: Creates measurable standards for leather usage and productivity.

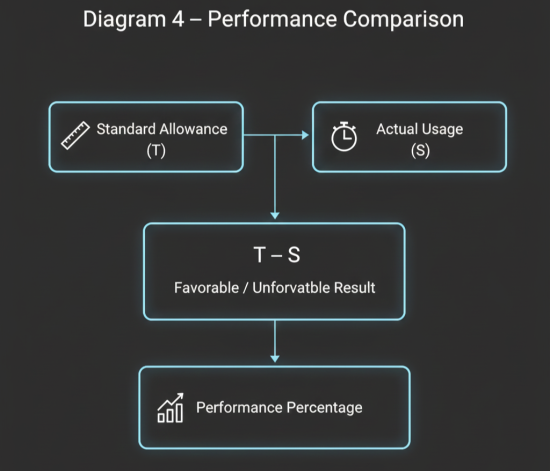

5. Clicking Performance & Material Usage Analysis

Purpose: Measure real cutting performance against standards.

Key Topics:

- Standard vs actual usage

- Favorable and unfavorable variance

- Clicker performance evaluation

Why It Matters: Transforms cutting data into management decisions and improvement actions.

Conclusion

This Cutting Control Series provides a complete, practical, and structured framework for managing leather usage in footwear manufacturing. When applied consistently, it enables factories to reduce waste, control costs, and improve cutting performance using objective data rather than assumptions.