Footwear Manufacturing Cutting-6 : Understanding Leather Stretch Direction

Estimated Reading Time: ~ 6-7 minutes

Introduction

In footwear manufacturing, cutting is not just a preparatory step—it is the foundation on which fit, comfort, and durability are built. Among all materials used for uppers, leather demands the highest level of technical understanding because it is a natural product. No two hides are the same, and each behaves differently during cutting, lasting, and wear.

One of the most critical aspects cutters must understand is leather stretch direction, often called the lines of tightness. When cutters ignore these natural stretch lines, even the best patterns and finest leather can result in distorted uppers, poor fit, and reduced product life.

Therefore, in this sixth part of our Cutting Series, we focus on how leather stretches, how different zones of the hide influence performance, and why correct cutting direction plays a decisive role in producing consistently high-quality footwear

Leather as a Natural Cutting Material

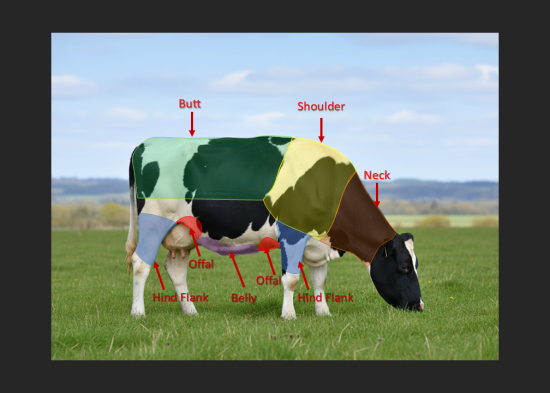

Leather is sourced from a wide variety of animals including cows, sheep, goats, pigs, calves, horses, kangaroos, ostriches, and deer. In the footwear industry, cow leather remains the most widely used material and is commonly split along the backbone to produce what is known as side leather.

What makes leather unique also makes it challenging.] Its fiber structure varies across the hide, creating differences in thickness, elasticity, and grain appearance. As a result, cutters cannot treat leather like a uniform synthetic sheet.] Instead, every hide requires careful assessment—especially when it comes to understanding how it will stretch during production and wear.

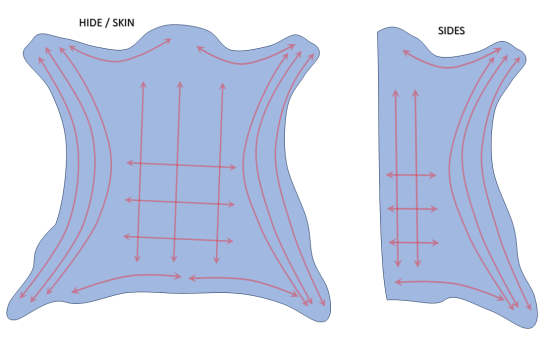

Understanding Leather Stretch Direction

Every hide contains natural stretch patterns that follow the alignment of collagen fibers in the skin. These patterns determine how the leather behaves when tension is applied during lasting and later during wear.

Generally, leather stretches more across the width of the hide and less along the backbone. This difference may appear subtle at the cutting stage, but its impact becomes highly visible once the shoe is lasted and worn. If components are cut without respecting these natural directions, the leather may stretch in unwanted areas, leading to shape distortion, wrinkling, and long-term fit issues.

For this reason, stretch direction should never be treated as a secondary consideration. It is a core quality parameter that must guide every cutting decision.

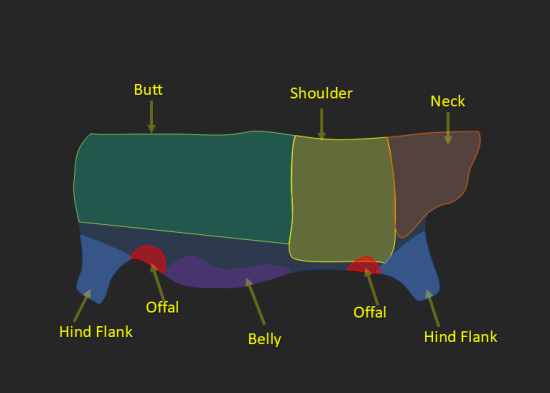

Leather Zones and Their Effect on Cutting Quality

A hide is not uniform from edge to edge. Different zones behave differently because of the way the animal’s skin functioned during life.

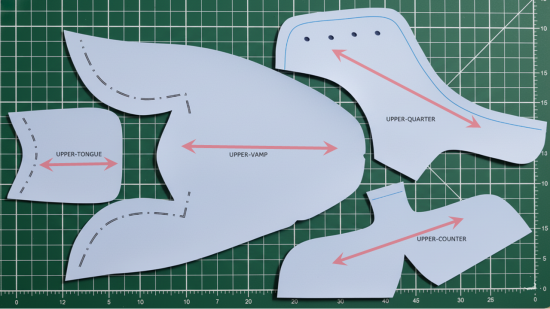

The area along the backbone is considered the most stable part of the hide known as Butt. The fibers here are closely packed, the grain surface is smoother, and the leather stretches the least. This makes it the preferred zone for major structural components such as vamps, quarters, and toe areas where shape retention is critical.

Moving toward the shoulders, the fiber structure becomes slightly more flexible. This region offers moderate stretch and is suitable for parts like facings, collars, and tongues that require some adaptability without losing form.

The belly area is the stretchiest part of the hide. The fibers are looser and more elastic, which makes this zone unsuitable for load-bearing components. However, it can still be effectively used for reinforcements, linings, and non-critical parts when selected carefully.

A well-defined product specification should always indicate not only which components are cut from which zones, but also the exact cutting direction for each part. This clarity removes guesswork and ensures consistency across production batches.

Why Stretch Direction Matters in Manufacturing

The importance of stretch direction becomes most evident during the lasting process. As the upper is pulled over the last, the leather is subjected to considerable tension, especially in the forepart. If the material stretches in the wrong direction, the upper may pull unevenly, the toe shape may collapse, and unwanted wrinkles can appear on the vamp and quarters.

Problems do not stop at the factory gate. During wear, shoes that were cut against the natural lines of tightness often lose their original fit. Customers may notice that the shoes feel loose after a short period, or that the shape no longer looks neat and symmetrical. These issues directly affect brand perception and lead to higher returns and complaints.

Correct stretch orientation ensures that the leather stretches only where it is supposed to, allowing the shoe to adapt naturally to the foot without losing its designed form.

Role of the Cutter, Assessor, and Quality Team

Maintaining control over stretch behavior is not the responsibility of one person alone—it requires coordination between assessors, cutters, and quality teams.

Leather assessors play a crucial role at the beginning of the process. They must evaluate the elasticity of each batch of leather and determine whether it is suitable for the intended product. Leather that stretches beyond acceptable limits may appear attractive but will fail in long-term performance.

Cutters translate this technical understanding into practice. They must align patterns with the natural lines of tightness, select appropriate zones for each component, and follow the cutting directions specified in the product sheet. Their skill and attention to detail directly influence how the upper behaves during lasting and wear.

Quality control teams complete the loop by monitoring finished uppers for early signs of distortion risk. Their feedback helps refine cutting practices and ensures continuous improvement.

Best Practices for Cutting with Stretch Direction

Experience across the footwear industry shows that consistent results come from disciplined cutting-room practices. Structural components should always be aligned in the heel-to-toe direction, which usually follows the natural line of tightness. High-stress areas must be cut from the backbone zone, while belly leather should be reserved for parts where stretch will not compromise shape.

Clear marking of stretch direction on cutting templates, combined with regular training for cutters, greatly reduces errors. Simple hand-feel checks and visual inspection before cutting can often prevent costly mistakes later in production. When these practices become routine, factories see measurable improvements in fit consistency, appearance, and product durability.

Conclusion

In Footwear Manufacturing – Cutting, understanding leather stretch direction is not a technical luxury—it is a fundamental requirement for quality. When the natural behavior of leather is respected, every stage of production benefits, from smoother lasting to better fit and longer product life.