Adhesive Concepts Glossary: Definitions and Terms Explained

Understanding Adhesive Terminology for Industry Experts

As we continue our adhesive series—building on the foundational insights from our first five blogs covering types, applications, and troubleshooting—it’s time to dive deeper into the lexicon that powers the industry. For example, whether you’re a footwear manufacturer referencing shoe uppers and soles or an engineer optimizing hot melt processes, mastering these terms ensures precise communication and innovation. In fact, this installment compiles a comprehensive glossary, organized alphabetically for easy reference. Furthermore, this resource highlights how everyday concepts like “adhesion” and “curing agents” intersect with practical challenges, such as avoiding voids or extending shelf life.

Why This Glossary Matters in Adhesive Technology

Adhesives aren’t just sticky solutions. Instead, they’re engineered systems where terminology dictates performance. For instance, understanding “potlife” can prevent costly mix errors in two-component formulations, while “tack” influences immediate bonding in assembly lines. Additionally, with the rise of sustainable materials, terms like “plasticizer” and “stabilizer” are crucial for eco-friendly adaptations. Moreover, it equips you to troubleshoot real-world issues, like adhesive failure in high-stress environments.

Key Terms and Definitions

Here’s the structured glossary for seamless reference. We’ve consolidated related concepts for clarity.

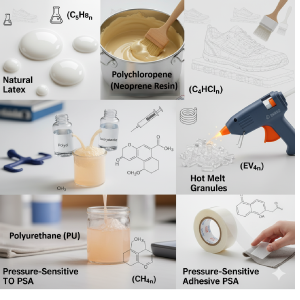

- Accelerator: A substance which speeds up a chemical reaction during the curing of an adhesive bond or solidification of a molten hot melt adhesive.

- Adherend: Materials or substrates used for attaching by means of an adhesive. Examples include shoe uppers, soles, and toe puffs.

- Adhesion: An adhesive, applied under specific conditions, establishes attraction between unlike charges in the adhesive and substrates, providing a bond with significant internal strength.

- Adhesive: The substance responsible for holding or bonding two substrates together, either temporarily or permanently.

- Adhesive Failure: Separation of bonded surfaces at the junction of the adherend and adhesive, or within the adhesive itself. For example, sole failure—separation of the sole from the upper.

- Aging of Adhesive: The gradual deterioration of adhesive properties over time.

- Binder: The property of an adhesive that binds or attaches two substrate surfaces or creates adhesion between them.

- Bond: The assembly of two substrates by an adhesive.

- Bond Strength: The force required to overcome either the adhesive strength of the bond or the cohesive strength of the adhesive material.

- Catalyst: Employed as curing agents to reduce curing time and increase polymer crosslinking. Catalysts remain unchanged, requiring only small quantities.

- Cement: Another term for adhesive; used to bind or adhere materials together.

- Characterization: A description of a material’s properties.

- Cohesion: Internal attractive forces among the molecules of an adhesive.

- Coverage: A measure of an adhesive’s ability to spread over adherend or substrate surfaces.

- Cure: The process by which an adhesive changes from a liquid to a solid state, establishing a bond between substrate surfaces.

- Curing Agents: Chemicals that react with the adhesive to form a film. For example, adding di-isocyanate to neoprene-based adhesive accelerates curing.

- Diluent: A chemical added to an adhesive for viscosity control and to achieve a thin, uniform film.

- Dry: On application, the adhesive’s solvent evaporates and is partially absorbed by porous substrates. (See also Force Dry.)

- Extrude: The molten hot melt adhesive is extruded through an orifice onto surfaces like a shoe’s insole or sole.

- Filler: A material or chemical used to improve an adhesive’s cost properties and reduce overall expense.

- Flash: Adhesive oozing out at joints, such as between a substrate upper and sole after bonding.

- Force Dry: Drying the adhesive by exposing it to air at higher temperatures.

- Functional Group: A chemically reactive group within the adhesive.

- Hardener: Chemicals added to an adhesive to promote curing.

- Inhibitor: Chemicals in an adhesive that prolong storage life.

- Modifier: A chemically inert ingredient that alters reaction properties; examples include fillers, thinners, plasticizers, stabilizers, or wetting agents.

- Mucilage: An adhesive with lower bonding strength.

- Open Assembly Time: The interval between applying adhesive to substrates and assembling them to another surface.

- Plasticizer: Reduces viscosity in adhesives; in hot melts, lowers reactivation temperature and enhances solidified flexibility.

- Potlife: The usable time for a two- or three-component adhesive after mixing; exceeding it increases viscosity, hindering spreading and wetting.

- Promoter: A substance that boosts adhesive activity.

- Retarder: A chemical added to slow the adhesive’s chemical reaction.

- Set: Equivalent to cure or dry. Setting Time: The duration needed to form a solid film via heat and/or pressure.

- Shelf Life or Storage Life: The period during which a manufacturer guarantees satisfactory performance under specified storage conditions, without deterioration.

- Softener: A material or chemical that prevents adhesive brittleness and imparts flexibility.

- Solvent: A liquid capable of dissolving another material.

- Stabilizer: A substance enhancing resistance to light, heat, radiation, and similar factors.

- Tack: The property achieved when a dried adhesive on a substrate enables bonding with sufficient stickiness.

- Thinner: Also called diluent or extender; a volatile liquid added to modify adhesive consistency or working properties.

- Void: An air pocket or discontinuity in the bond line.

- Viscosity: The internal frictional resistance to adhesive flow, or a liquid’s ability to resist flowing.

- Wetting: The interfacial ability of a liquid to intimately contact the surface it flows over.

- Working Life: The period an adhesive maintains its properties after mixing with activators, solvents, catalysts, or other ingredients.

How Adhesives Work in Real Applications

In practice, adhesives bond materials such as leather, rubber, and plastics. For instance, hot melt systems rely on extrusion, while solvent-based ones need force drying. Additionally, curing agents speed up reactions, whereas inhibitors extend shelf life. As a result, understanding open assembly time prevents weak bonds. Similarly, wetting ensures full coverage, and tack enables instant grip. Therefore, each term plays a role in quality control and performance.

Conclusion: Empowering Your Adhesive Expertise

In wrapping up this deep dive into adhesive terminology, remember that a strong vocabulary is the foundation of effective bonding—much like adhesion itself holds substrates together. By internalizing these definitions, you’ll navigate formulations with confidence, minimize failures, and innovate sustainably. As our adhesive series progresses, stay tuned for hands-on guides to implementation. What’s your go-to term in daily work? Share in the comments below, and let’s keep the conversation sticky!