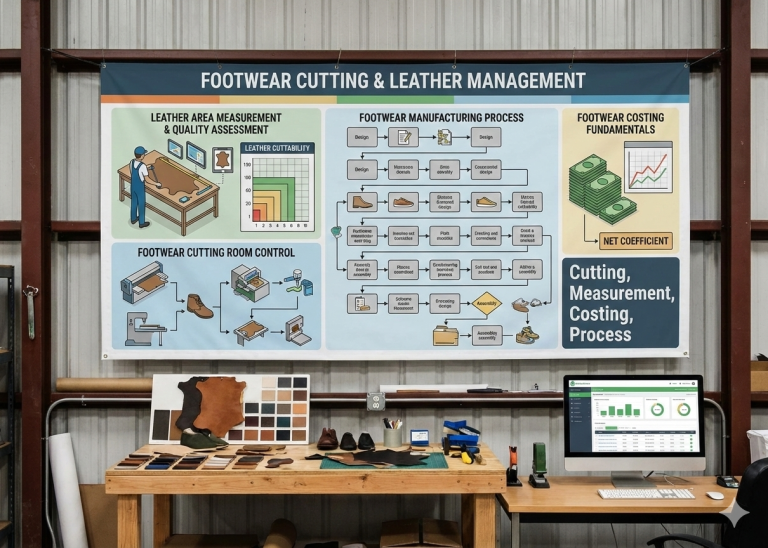

Types of Footwear Adhesives: From Latex to Hot Melt

Introduction

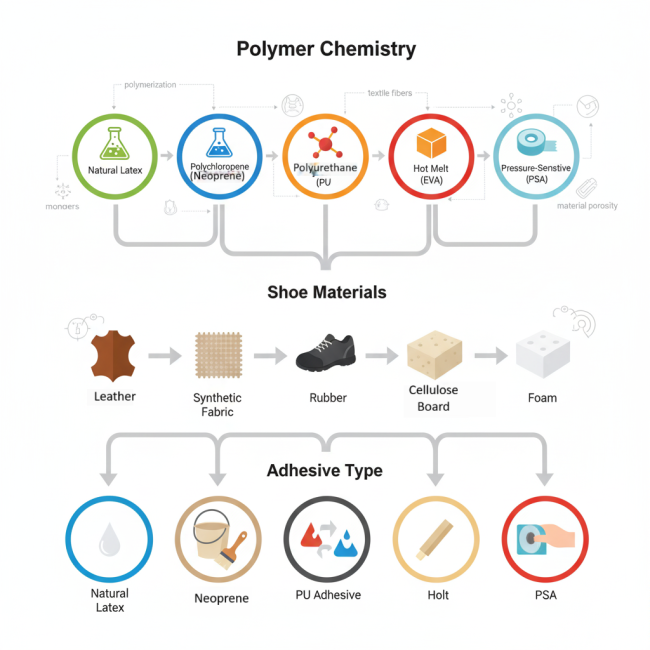

Building on our series, where we first explored polymer chemistry’s role in adhesives and then examined how shoe materials influence bonding, we now dive into the footwear adhesives types themselves. These adhesives are the key contributor of shoe assembly, ensuring materials like leather and synthetics hold together under stress. From natural latex’s flexibility to hot melt’s quick set, each type offers unique properties tailored to production needs. For example, water-based options prioritize eco-friendliness, while reactive polyurethanes deliver unmatched strength. In this post, we’ll break down key types, their ingredients, and applications. Moreover, this prepares us for future discussions on advanced adhesive systems. Let’s get started!

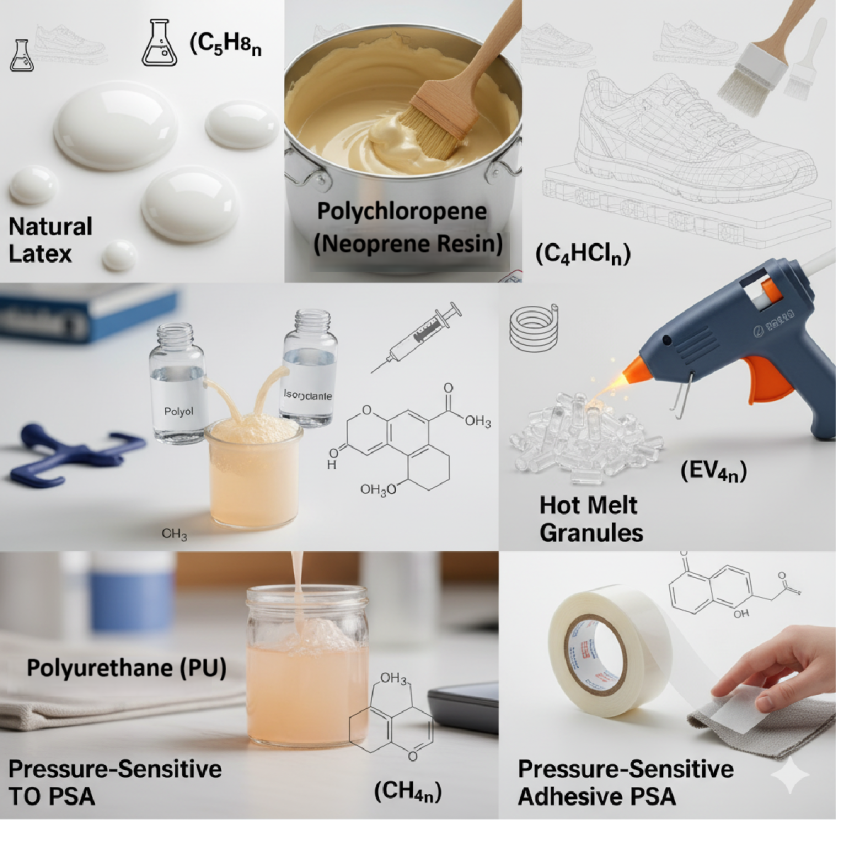

Natural Rubber and Latex Adhesives

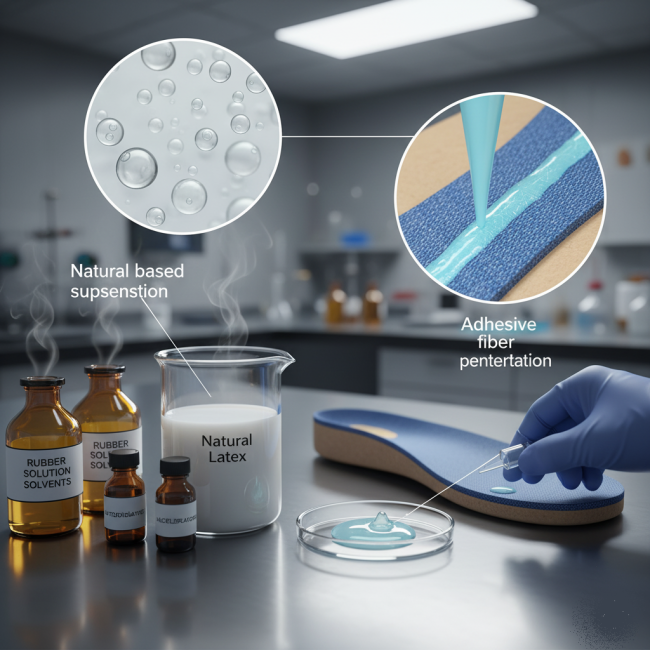

Natural rubber and latex adhesives provide versatile, cost-effective bonding for footwear, drawing from rubber’s elastic properties. We begin with water-based latex, then cover rubber solutions, modified rubbers, and pure natural latex.

Water-based latex consists of rubber particles suspended in water, often at 60% solids content. Manufacturers use it for temporary bonding, as it dries to a tacky film. Additionally, it suits porous materials like leather, where water evaporates to leave a flexible bond. Rubber solutions, dissolved in solvents like hexane or heptane, offer higher viscosity for precise application. They excel in sole attaching, providing strong initial tack.

Modified rubbers enhance performance by adding resins or antioxidants, reducing crystallization and improving heat resistance. Natural rubber latex adhesive, milky and non-vulcanized, bonds via coagulation—ideal for upper to sole joins. However, it requires stabilizers to prevent premature setting.

These adhesives shine in low-cost production, with latex’s eco-profile appealing to sustainable brands. For instance, vulcanized versions add Sulphur for durability. Transitioning to preparation, mix latex with fillers like clay for viscosity control. In summary, natural rubber types balance flexibility and economy, but demand careful handling to avoid skin formation.

Polychloroprene Adhesives

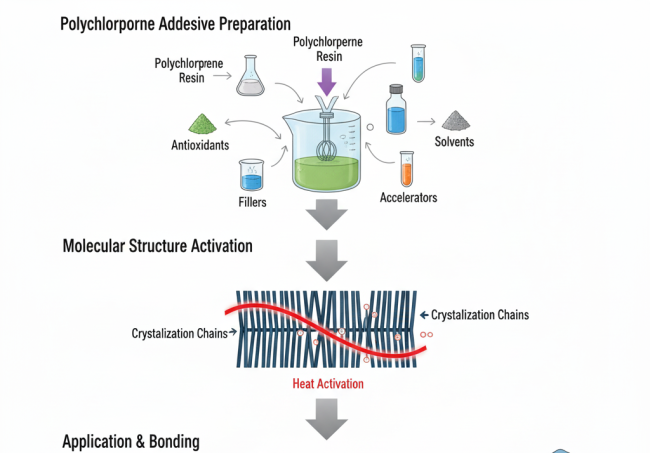

Polychloroprene, commonly known as Neoprene, delivers robust, heat-resistant bonds in footwear. This synthetic rubber adhesive consists of polychloroprene polymer, often in solvent systems like toluene or ketones.

Ingredients include resins for tack (e.g., phenolic or terpene), antioxidants to prevent oxidation, solvents for dissolution, fillers like calcium carbonate for bulk, and accelerators such as zinc oxide for cure speed. Crystallization, a key trait, increases strength as the polymer chains align—enhanced by magnesium oxide stabilizers.

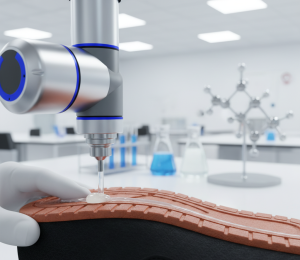

Preparation involves dissolving polychloroprene in solvents, then blending resins and fillers under agitation. The mixture matures for 24 hours to optimize viscosity. For use, apply to surfaces, allow solvent evaporation.

In footwear, polychloroprene suits sole attaching due to its 70% solids content and resistance to flexing. However, ventilation is crucial during application to handle fumes. Furthermore, it outperforms latex in oily environments, making it a staple for work boots

Polyurethane Adhesives

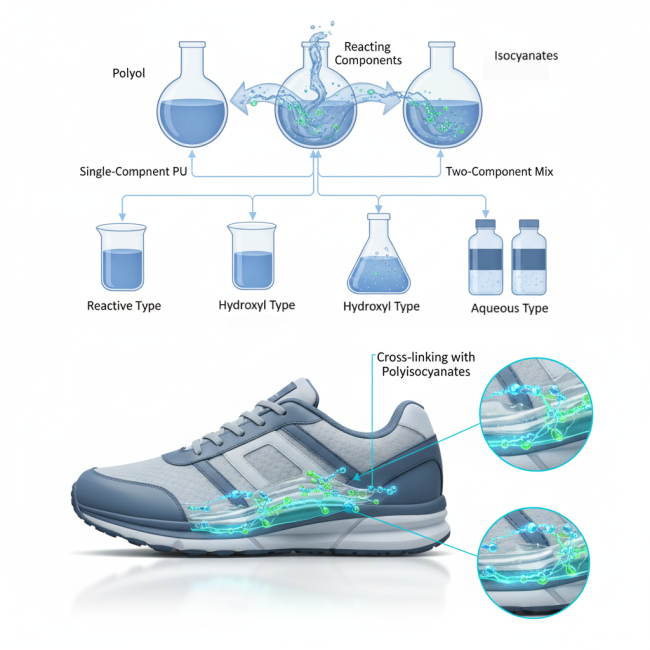

Polyurethane (PU) adhesives dominate high-performance footwear bonding, thanks to their versatility and strength. PU ingredients center on polyols (polyether or polyester) and isocyanates (e.g., MDI 1or TDI2), reacting to form urethane links.

Isocyanates enable cross-linking, with MDI for rigid bonds and TDI for flexible ones. Single-component PU cures with moisture, while two-component mixes polyol and isocyanate for controlled reactions. Classification includes:

- Reactive: These one- or two-part systems form strong, heat-resistant bonds via isocyanate-polyol reactions. For example, moisture-cure types absorb atmospheric water, ideal for sole attaching.

- Hydroxyl solvent adhesives: Dissolved in solvents, they evaporate to leave tacky films, bonding via heat. They suit temporary holds but require primers for non-porous surfaces.

- Aqueous dispersions: Water-based PU particles coagulate on drying, offering eco-friendly options with low VOCs. They excel in lining attachments, though slower curing demands accelerators.

Accelerators, hardeners, or cross-linking agents like polyisocyanates boost reaction speed, adding 2-5% to formulations. In practice, PU adhesives resist hydrolysis better than latex, suiting athletic shoes. Preparation mixes components under inert gas to prevent premature curing.

Hot Melt Adhesives

Hot melt adhesives revolutionize footwear assembly with solvent-free, rapid bonding. They establish effective bonds by melting at 140-200°C, flowing into surfaces, then solidifying on cooling.

Performance highlights include high initial strength and flexibility, resisting peel and shear. Formulations vary: Polyesters, prepared by reacting diols with dicarboxylic acids, suit shoe making for their heat stability. For outsole attaching, polyesters provide 100% solids bonds, applied via nozzles.

Temporary bonding uses lower-melt versions for quick tacks. Polyamide or cellulose polymers offer alternatives—cellulosic hot melts, from esterified cellulose, bond porous materials like insoles. Hot melt films, thin sheets of EVA or polyamide, laminate under pressure for uniform coverage. Polyamides hot melt adhesives, derived from dimer acids, excel in oily resistance for work boots.

Preparation heats granules to liquid, then extrudes or sprays. In footwear, they reduce drying time, enhancing production efficiency. However, high temperatures limit use on heat-sensitive materials.

Pressure Sensitive Adhesives (PSA)

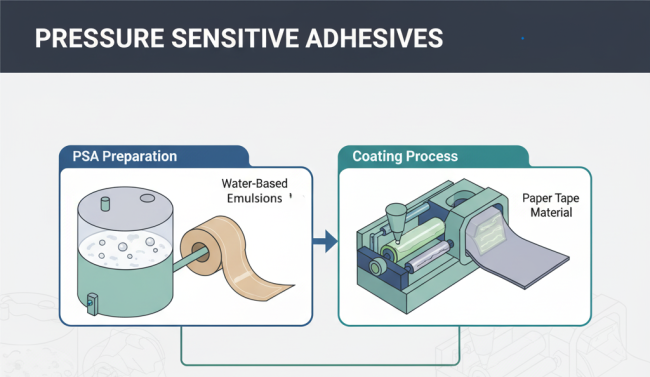

Pressure sensitive adhesives (PSA) bond with light pressure, no heat or solvent needed. Backing materials include paper, film, or fabric, coated with PSA for tapes or labels.

Water-based PSA, emulsions of acrylic or rubber, offer low VOCs and easy cleanup. They suit shoe fabrication for attaching linings or temporary fixes. Formulations include polymers like polyacrylate for tack, resins for cohesion, and plasticizers for flexibility.

In footwear, PSA tapes reinforce seams or hold components during assembly. Their open time allows repositioning, but strength develops over 24 hours. Preparation disperses polymers in water with emulsifiers, then coats onto backings.

These adhesives complement hot melts, providing instant tack where heat isn’t feasible.

Conclusion

Navigating footwear adhesives types reveals a world of innovation, from latex’s natural flexibility to PU’s reactive power. Each type—natural rubber, polychloroprene, polyurethane, hot melt, and PSA—addresses specific bonding needs in shoe production. For instance, hot melts speed lines, while PSAs enable precise adjustments. As we conclude this third installment, these adhesives bridge materials from our prior post, setting up our next on full adhesive systems. Questions? Comment below!

Subscribe for more footwear insights.