Stitching Machines in Footwear Manufacturing: A Detailed Technical Guide

In modern footwear production, upper stitching is regarded as one of the most skilled and critical operations within the manufacturing process. It plays both a structural and visual role in the finished shoe. As a result, stitching quality directly influences product durability, visual appeal, and overall brand perception. Even minor inconsistencies in stitch formation, seam alignment, or thread tension become clearly visible in the finished article.

For this reason, a clear understanding of stitching machines, their construction, feed mechanisms, and correct applications is essential for footwear professionals involved in production, quality assurance, and process engineering.

Role of Upper Stitching in Footwear Manufacturing

Upper stitching performs two primary functions in footwear construction. Firstly, it serves a functional role by securely joining individual upper components to form a stable structure. Secondly, it performs a decorative role, where visible stitch lines contribute directly to the design language of the shoe.

Because stitching remains exposed in the finished product, it must be executed with a high level of consistency. Therefore, manufacturers select stitching machines based on seam type, material thickness, component shape, and stitching accessibility. When the correct machine is selected, seam strength and visual uniformity are consistently achieved.

Understanding Stitch Formation and Machine Elements

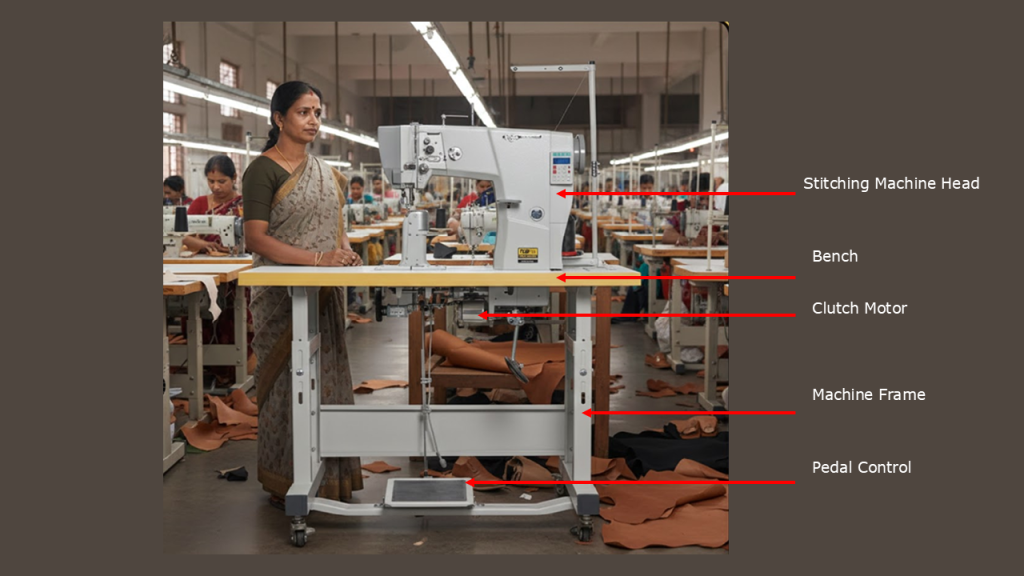

To fully understand stitching quality, it is important to consider the individual elements involved in stitch formation. In this context, each component of the stitching workstation contributes directly to seam accuracy and consistency.

A typical stitching setup includes:

- The stitching machine head, which controls needle penetration, hook movement, and thread interlocking

- The bench or machine frame, which provides operational stability

- The motor, which drives the needle bar and feed mechanism

- The operator chair and foot control, which enable speed regulation

- Guides, folders, and attachments, which ensure consistent stitch placement

When these elements operate in coordination, operators guide components accurately while the machine produces uniform and repeatable stitches.

Types of Stitch Formation Used in Footwear

Furthermore, different stitch formations are used in footwear depending on functional and aesthetic requirements.

Lockstitch remains the most commonly used stitch in footwear manufacturing. It interlocks top and bottom threads within the material, producing a strong and secure seam suitable for most upper constructions.

By comparison, chain stitch uses a single thread and allows faster sewing speeds. However, manufacturers apply it selectively due to lower seam security.

Meanwhile, overlock stitch is primarily used for edge finishing and lining preparation rather than for visible upper stitching operations.

Flat Bed Stitching Machines

Flat bed stitching machines are among the most widely used machines in footwear stitching rooms. These machines feature a flat working surface that fully supports components during stitching.

Operators typically use flat bed machines when components remain relatively flat throughout the operation. As a result, the flat surface provides good visibility and control, allowing consistent stitch alignment and uniform seam appearance.

Typical applications include:

- Upper panels

- Tongues and facings

- Flat reinforcements

- Decorative stitching

However, in practice, flat bed machines become less effective when components require stitching around three-dimensional shapes.

Pro Tip: Flat bed machines perform best when components are fully supported on the bed. Allowing material to hang or twist often results in uneven stitch length and waviness in decorative seams.

Post Bed Stitching Machines

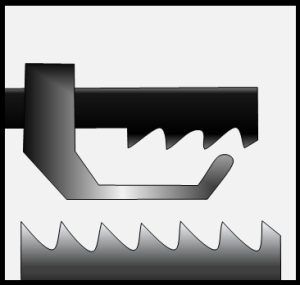

Post bed stitching machines are designed for complex and three-dimensional components. In contrast to flat bed machines, the stitching area is elevated on a vertical post, allowing operators to rotate components freely around the needle.

This configuration provides excellent access to tight curves and edges, making post bed machines ideal for pre-shaped uppers and visible edge stitching.

Common applications include:

- Edge stitching

- Decorative multi-row stitching

- Pre-shaped upper components

Pro Tips : During post bed stitching, components should be rotated smoothly rather than pulled forward. Controlled rotation maintains stitch spacing and prevents edge distortion.

Feed Mechanisms in Stitching Machines

Feed mechanisms control material movement during stitching and significantly influence stitch consistency and seam appearance.

By comparison, the drop feed mechanism advances material in small steps and suits general stitching operations. However, visibility becomes limited when stitching curved or decorative seams.

In addition, the wheel feed mechanism replaces traditional feed dogs with a rotating wheel. This system improves visibility and control, particularly for decorative and curved stitching applications.

Pro Tip : Wheel feed systems are recommended for visible upper stitching, as improved visibility reduces correction movements and stitch irregularities.

Cylinder Arm Stitching Machines

Cylinder arm stitching machines share similarities with post bed machines but feature a horizontal cylindrical arm. Consequently, components can be passed around the arm, providing easy access to enclosed or tubular areas.

These machines are commonly used for:

- Shoe openings

- Insole attachment

- Fully formed uppers

Pro Tip: Cylinder arm diameter should closely match the internal shape of the component. Proper clearance improves stitch accuracy and operator control.

Zigzag Stitching Machines

Zigzag stitching machines produce stitches with lateral needle movement, forming a zigzag pattern. As a result, seams retain flexibility while allowing decorative variation.

Manufacturers commonly use zigzag stitching where elasticity is required or where decorative reinforcement is needed without increasing seam bulk.

Pro Tip: Zigzag width and stitch density must be validated before bulk production. Excessive width weakens seams, while insufficient width reduces flexibility.

Heavy-Duty Stitching Machines

Heavy-duty stitching machines are designed for thick and dense materials. These machines deliver higher penetration force and robust construction.

Typical applications include:

- Thick leather uppers

- Safety and outdoor footwear

- High-strength seam requirements

Pro Tip: Needle and thread sizes must be carefully matched to material thickness. Incorrect selection often causes thread breakage or surface perforation.

Automatic and Computer-Controlled Stitching Machines

Automatic stitching machines reduce operator dependency and improve consistency. Programmed stitch paths allow complex decorative patterns to be reproduced accurately.

Consequently, these machines are widely used in high-volume production environments

Pro Tip: Programs must be validated using actual production materials. Material variation, especially in leather, can affect stitch alignment.

Common Stitching Defects, Likely Causes, and Machine Involvement

| Common Defect | Likely Root Cause | Machine Type |

|---|---|---|

| Uneven stitch length | Inconsistent feeding | Flat bed, Drop feed |

| Skipped stitches | Incorrect needle selection | Flat bed, Post bed |

| Wavy seams | Poor material support | Flat bed |

| Edge distortion | Excessive pulling | Post bed |

| Thread breakage | Needle–thread mismatch | Heavy-duty |

| Misaligned decoration | Poor visibility | Wheel feed |

Therefore, defect analysis must always consider machine selection and feed mechanism.

Do and Don’t Guidelines for Stitching Operators

Do

- Maintain controlled pedal operation

- Support components fully

- Match needle and thread to material

- Conduct trial stitching

- Keep guides clean and aligned

Don’t

- Do not pull components aggressively

- Do not use flat bed machines for complex curves

- Do not change settings without approval

- Do not ignore early stitch defects

Machine Selection Flow for Upper Stitching

- Flat panels → Flat bed → Drop / Wheel feed

- Curved edges → Post bed → Wheel feed

- Tubular components → Cylinder arm → Wheel feed

- Decorative flexible seams → Zigzag machine

- Thick materials → Heavy-duty machine

- High-volume patterns → Automatic machine

Inspector’s Checklist for Stitching Quality

- Stitch length consistency

- Accurate stitch alignment

- No skipped stitches or loops

- Balanced thread tension

- No leather perforation damage

- Smooth seam appearance

- Match with approved sample

Conclusion

In conclusion, stitching machines form the backbone of footwear upper manufacturing. Each machine type serves a specific purpose, and incorrect selection leads to quality defects and production inefficiencies. By understanding machine capabilities, feed mechanisms, and operational controls, footwear manufacturers achieve consistent, high-quality stitching that meets both functional and aesthetic requirements.

Global Footwear Stitching Machine Manufacturers

1. Juki Corporation (Japan)

Juki Corporation, founded in Tokyo in 1938, is a globally recognized leader in industrial sewing machines. Renowned for precision, reliability, and innovation, Juki’s equipment is widely used in garment, upholstery, and footwear production. Their industrial models feature advanced feed systems, digital controls, and strong build quality, making them ideal for high-volume stitching and heavy materials. Juki supports a broad global service network for parts and technical support.

Official Website: https://www.juki.co.jp/en

2. PFAFF (Germany / SVP Worldwide)

PFAFF has a rich heritage dating back to 1862 in Kaiserslautern, Germany, where it first built precision sewing machines, including leather-capable models. Today it operates under SVP Worldwide and continues to produce industrial stitching systems known for superior control, robust build, and engineering excellence. PFAFF machines are widely used in heavy duty and technical stitching applications, including footwear and automotive textiles.

Official Website: https://www.pfaff-industrial.com/en/portfolio/sewing-machines

3. Golden Wheel (Taiwan / China)

Golden Wheel, produced by Chee Siang Corporation, is a major industrial sewing machine brand based in Taiwan with manufacturing in Shanghai. The company specializes in a wide range of industrial machines, including lockstitch, post bed, roller feed, and specialized footwear sewing units. Golden Wheel machines are valued for dependable performance, mechanical stability, and cost-effective solutions across shoe, garment, and leather goods production.

Official Website: https://www.golden-wheel.com/en/

4. Brother Industries (Japan)

Brother Industries, headquartered in Nagoya, Japan, offers industrial sewing systems renowned for user-friendly operation and versatile applications. While popular in apparel and embroidery markets, Brother’s heavy-duty industrial units are also used in technical stitching setups such as footwear upper assembly. The brand is recognized for its automation features, energy-efficient designs, and strong global support infrastructure.

Official Website: https://industrialsewingmachine.global.brother/en-ap

5. Durkopp Adler (Germany)

Founded in 1860 and headquartered in Bielefeld, Durkopp Adler is a leading German industrial machine manufacturer, especially for heavy duty applications. Its machines are engineered for high performance, precision stitch control, and durability — making them suitable for leather goods, footwear uppers, and thick materials. Durkopp Adler emphasizes automation, electronic control, and ergonomic design for industrial production environments.

Official Website: https://www.duerkopp-adler.com/index/