Shoe Shanks Explained: Types, Materials, Manufacturing & Their Essential Role in Footwear Design

Estimated Reading Time: ~ 6-7 minutes

Shoe shanks are among the least glamorous yet most vital components in footwear. Often taken for granted by manufacturers and consumers alike, shoe shanks only gain attention when something goes wrong—transforming a hidden asset into an expensive liability. In reality, a shoe shank is one of the most severely stressed parts of a shoe, providing essential torsional support for the arch while enduring heavy bending, forepart, and heel stresses throughout the shoe’s entire lifespan.

This comprehensive guide covers the evolution, purpose, types, materials, detailed manufacturing (especially steel), and importance of shoe shanks, incorporating both modern practices and historical technical insights from footwear engineering sources.

The Evolution of Shoe Shanks

Shoe shanks have been integral to footwear construction for centuries. Early shoemakers relied on natural materials such as wood, leather, or stiff cardstock to reinforce the arch and maintain structure. Wooden shanks — including parallel-sided designs for women’s and children’s shoes, or shaped “corset” styles for men’s footwear — were particularly common in traditional construction.

As demands grew in military, industrial, and work environments during the 19th and 20th centuries, steel shanks became the standard for superior durability and puncture protection. Fiberboard alternatives also emerged for lighter, more flexible applications.

In modern times, advanced materials like fiberglass, nylon, composites (e.g., Kevlar blends), and TPU provide better balance of strength, flexibility, and lightweight performance for athletic, hiking, and specialized footwear.

Purpose and Function of a Shoe Shank

A shoe shank is a supportive strip placed between the insole and outsole, typically under the arch area. Though hidden, its impact is profound.

Key Functions:

- Arch Support — Reduces strain on the foot’s arch and improves posture.

- Stability — Prevents over-flexing, twisting (torsion), and enhances balance.

- Durability — Helps shoes retain shape and last longer under repeated stress.

- Protection — Shields feet from sharp objects and uneven terrain.

- Energy Transfer — Improves propulsion and walking/running efficiency.

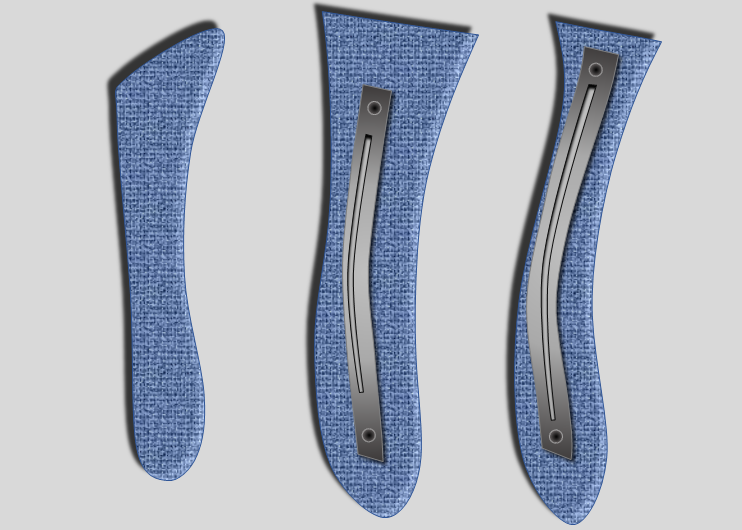

Types of Shoe Shanks

Shoe shanks vary by length, design, and application:

- Full-Length — Runs heel to toe; maximum rigidity for heavy-duty boots.

- Three-Quarter — Covers heel and arch; balances support and flexibility.

- Half Shank — Arch only; used in dress, ballet, and lighter shoes.

- Removable — For orthopedic/customizable footwear.

Traditional varieties include wooden (parallel-sided or shaped), fiberboard (with staple cut-outs), and diverse steel profiles (parallel-sided, V-shaped, thorn-fastened).

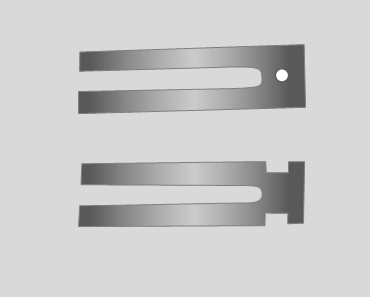

Examples of various steel shank designs:

Materials Used in Shanks and Comparison

| Material | Properties & Best Use Cases |

|---|---|

| Steel | Rigid, durable, puncture-resistant; ideal for work/safety boots. Hardened to Rockwell C 46-53. |

| Wood | Flexible, traditional; used in lower-heel men’s/women’s/children’s shoes (up to 30mm heels). |

| Fiberboard | Lightweight, affordable; doubles as shank + waist filler in casual/lighter footwear. |

| Fiberglass | Lightweight, flexible, non-conductive; hiking & athletic shoes. |

| Nylon | Affordable, light; casual & budget footwear. |

| Composite/TPU | Balanced strength-to-weight; versatile sports, modern boots, high-performance use. |

Steel Shank Manufacturing & Design (Detailed Technical Insights)

Steel shanks are typically made from carbon steel conforming to standards like British CS.50 (.50–.55% carbon, with controlled silicon, manganese, and low sulfur-phosphorus). The steel is supplied fully annealed and skin-rolled.

Manufacturing Process:

- Steel undergoes directional rolling at the mill, preserving non-metallic inclusions (less than 2% of composition, so minimal impact on strength).

- Shanks are cut and pressed from sheet steel.

- Common thicknesses: 1.2 mm (18 SWG) and 1.42 mm (17 SWG).

- Widths: 9.5 mm (3/8 in.) or 12.7 mm (½ in.), though custom sizes exist.

- After pressing, shanks are oil-hardened/tempered or austempered (isothermal hardening: heated to 865°C in salt bath, quenched to 310°C, no further tempering needed—yielding consistent shape, clean blue finish, and Rockwell C 46–53 hardness).

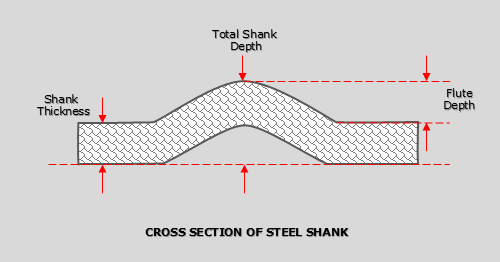

Flute Design:

Shanks feature a characteristic flute (corrugated profile) for added strength. Flute height (1.27–1.9 mm) depends on required rigidity, with total depth approximating flute height plus steel thickness.

Here are diagrams illustrating ideal shank cross-sections (fluted profiles):

Design Guidelines:

- Rear/Front Ends: Attachment holes (eyelet/staple) positioned close to edges; full flute height extends near ends.

- Dimensions vary by heel height (e.g., minimum total shank depth for 50–74 mm heels: 2.82–3.40 mm depending on width).

- Measured 32 mm from rear end

Why Shoe Shanks Matter

From traditional wooden reinforcements to precision-engineered steel and modern composites, shoe shanks are foundational. They ensure structural integrity, comfort, injury prevention, and longevity — especially in demanding activities. As footwear evolves, shanks become increasingly specialized for biomechanics and specific needs.