Footwear Manufacturing Insights: Advanced Pattern Techniques for Derby and Laced Styles

Reading Time : 3 Minutes

This article is prepared by extracting and interpreting the technical guidance shown in the provided reference images and aligning it with earlier blog-writing instructions used for FootwearEdge. The focus is Pattern technique in footwear manufacturing and upper design techniques that improve fit—both critical for productivity, quality, and wearer comfort.

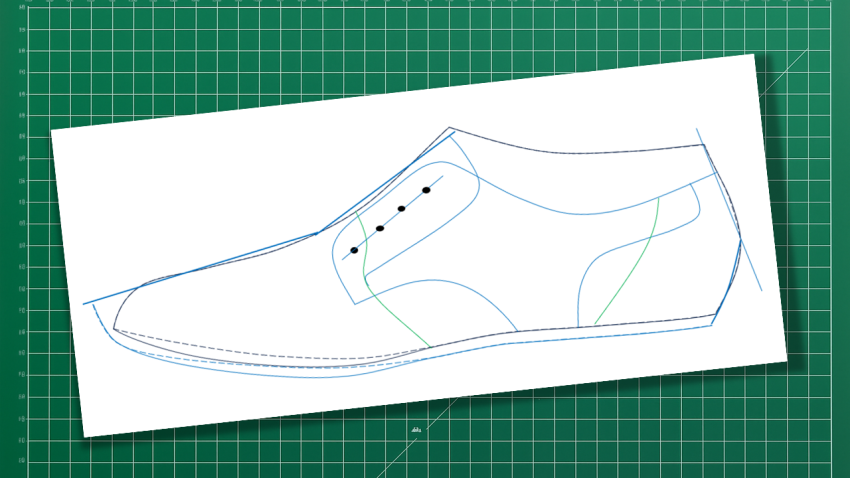

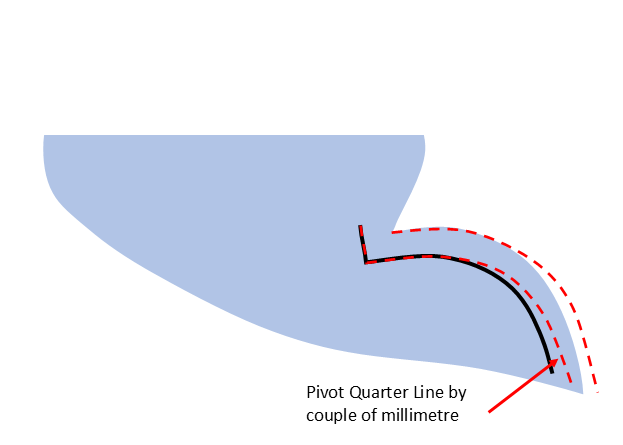

Pivoting the Quarter Upwards for Superior Pattern Fit

In footwear manufacturing, precise pattern adjustments significantly enhance the final product’s fit and aesthetics. One effective technique involves pivoting the quarter upwards in Derby shoe patterns. This method introduces controlled upward adjustments—often in increments of several millimeters—to the vamp wing area. By pivoting the quarter, manufacturers achieve improved contouring around the instep and quarter regions.

The process creates a smoother transition from the vamp to the quarter, reducing excess material bunching and ensuring a more tailored appearance. Patterns benefit when multiple small pivots are added, allowing for better accommodation of foot curvature without compromising structural integrity. This approach is particularly valuable in Derby constructions, where open lacing demands flexibility in pattern shaping.

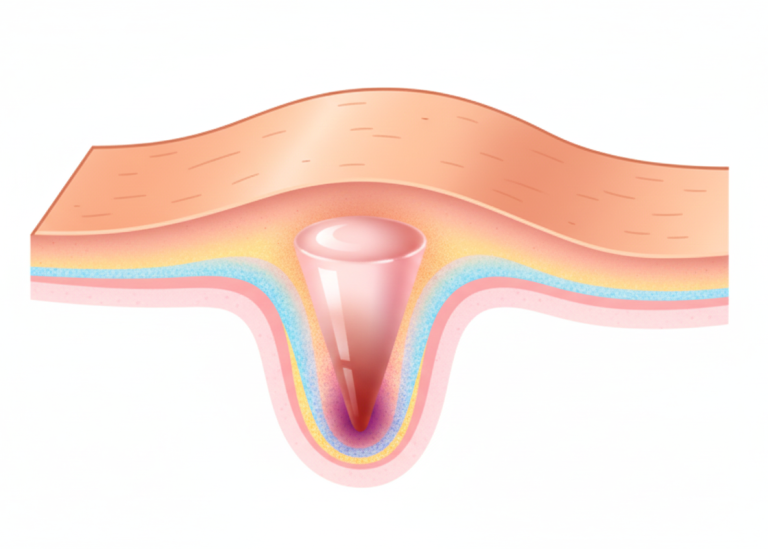

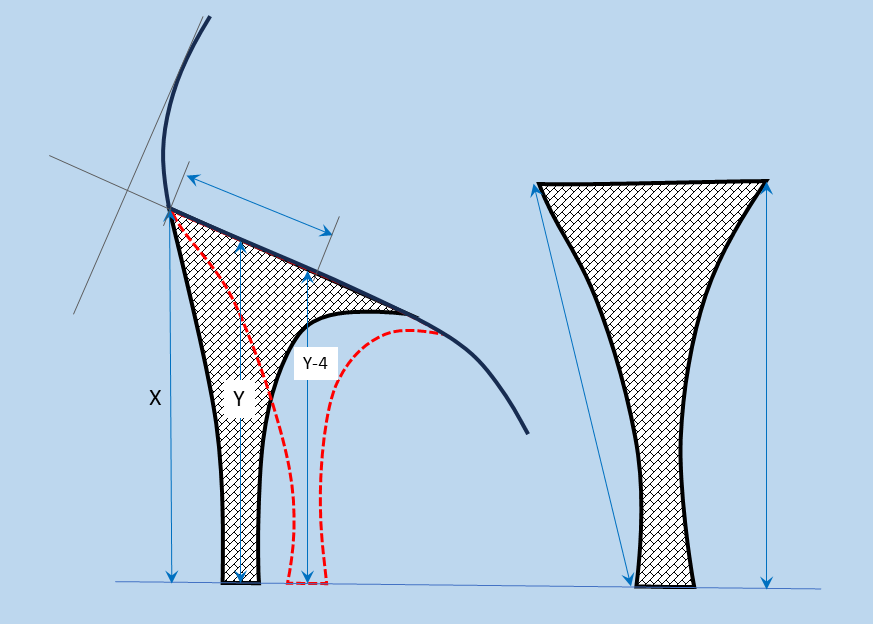

Accurate Measurement of Heel Height on Shoe Lasts

Heel height measurement remains a critical yet challenging aspect of last design and pattern development. Multiple methods exist, often yielding varying results due to differences in reference points and angles. Techniques include vertical measurements from the heel base, sloping lines aligned with the last’s pitch, and comparative lines marked across key zones (such as 35 mm references with Y-variations from 1 mm to 6 mm).

The most reliable approach utilizes a defined line (often labeled X) that accounts for the last’s natural slope and heel seat. This method minimizes discrepancies caused by heel styling or curvature. Accurate heel height ensures proper balance, toe spring, and overall posture in the finished shoe. Inconsistencies in measurement can lead to fit issues, making standardized protocols essential for consistent production.

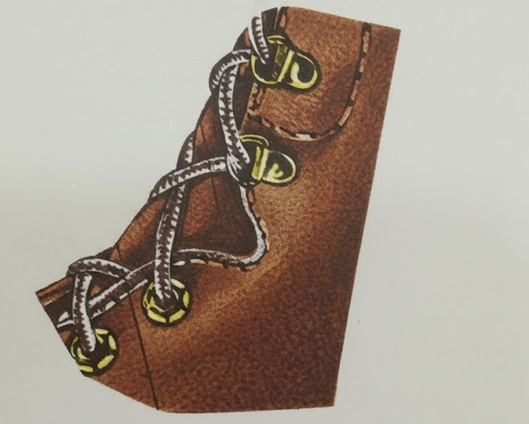

Enhanced Flexing and Comfort in Laced Boots

Laced boots require thoughtful design to facilitate natural foot movement during walking. A key feature involves creating a small indentation at the instep area. This indentation, strategically placed at the flex point, removes unnecessary leather resistance and promotes easier creasing.

By incorporating this design, weight transfer rolls forward smoothly, reducing crease formation across the vamp and improving overall articulation. The result is enhanced forward motion and reduced fatigue. Such refinements are especially beneficial in laced constructions, where adjustable tension must align with dynamic foot flexing without restricting gait.

These insights underscore the precision required in modern footwear manufacturing, where small technical adjustments yield substantial improvements in comfort, durability, and style.