Cutting Different Types of Leather: Best Practices for Footwear Manufacturing

Estimated Reading Time: ~ 6-7 minutes

Introduction

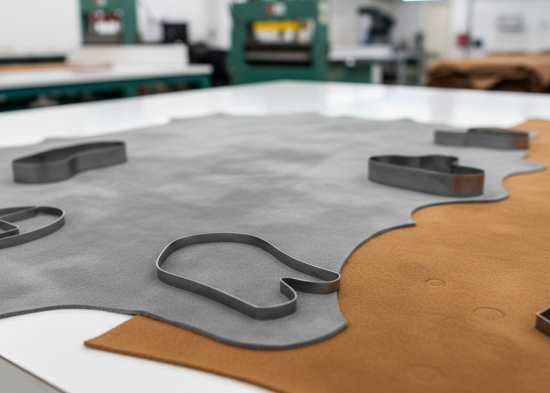

In footwear manufacturing, cutting accuracy is not only about precision—it directly impacts product quality, consistency, and material utilization. While general cutting rules apply to all materials, different types of leather demand specialized handling and techniques. Understanding how each leather behaves during cutting helps minimize defects, improve appearance, and ensure long-term durability of footwear.

This guide explains the correct cutting approach for suede, nubuck, corrected leather, full-grain leather, milled leather, and printed skins.

1. Suede and Nubuck Leather

Suede and nubuck have a directional surface finish, meaning their appearance changes based on cutting direction.

Key cutting guidelines:

- Always follow nap direction instructions strictly.

- Limit die rotation as specified in cutting guidelines.

- Prefer pair cutting instead of zone cutting for better shade and texture consistency.

- Inspect both grain side and flesh side carefully for:

- Loose fibre areas

- Reduced thickness

- Flay cuts or hidden damage

Why it matters:

Ignoring direction can cause visible shade mismatch between left and right shoes, leading to customer rejection.

2. Corrected Leather

Corrected leather features an artificial surface layer that improves visual uniformity.

Cutting considerations:

- Do not rely only on appearance—inspect every area carefully.

- Artificial finishes can hide:

- Weak fibre structure

- Internal defects

- These weaknesses often appear later during lasting or wear.

Best practice:

Cutters must treat corrected leather as visually consistent but structurally variable.

3. Full-Grain Leather

Full-grain leather displays natural marks and characteristics, which are valued for premium footwear.

Critical requirements:

- Cutting instructions must clearly define:

- Which natural marks are acceptable

- Which must be avoided

- Which components can use character areas

- High-end products demand controlled selection, not random cutting.

Quality focus:

The beauty of full-grain leather lies in its authenticity—but only when managed correctly.

4. Milled Leather

Milled leather undergoes additional processing to create a soft hand-feel and textured pattern.

Challenges in cutting:

- Pattern depth varies across the skin.

- Areas from the belly side usually show:

- Looser fibres

- Reduced strength

- Less visible milling effect

Operational best practices:

- Clearly define which components can be cut from:

- Strong areas

- Weaker areas

- Sort skins before issuing to cutting:

- Match similar milling levels

- Reduce visual variation

- Prefer selective cutting over match-marked cutting to improve efficiency.

5. Printed and Embossed Skins

Printed skins often imitate exotic leathers like reptile patterns but are made from embossed cowhide.

Major cutting risks:

- Uneven emboss depth across the skin:

- Backbone retains pattern best

- Flanks and shoulders show weaker embossing

- Pattern joins from embossing sections can disrupt visual flow.

- Scale size variation can cause mismatch between left and right shoes.

Cutting rules:

- Ensure all visible parts come from consistent emboss depth zones.

- Avoid cutting across pattern joints.

- Always match scale size between shoe pairs.

Conclusion

Different types of leather require more than basic cutting skill—they demand material understanding, visual judgment, and strict process discipline. Whether working with suede, corrected leather, full-grain hides, or embossed skins, success depends on:

- Clear cutting instructions

- Proper inspection before cutting

- Controlled selection of cutting zones

- Consistency between left and right components

By applying the right techniques for each leather type, footwear manufacturers can significantly improve product quality, yield efficiency, and customer satisfaction.