Footwear Manufacturing Insights: Match Marking Systems for Size, Pairing & Quality Control

Reading Time : 6-7 Minutes

Introduction

In footwear manufacturing, accuracy at every stage determines final product quality. One of the most overlooked yet critical control systems is match marking—also known as component identification, pair control marking, or production traceability marking.

Whether uppers are made from leather, synthetic materials, or textiles, each cut component must be correctly identified to ensure it reaches the right process, is stitched with its correct pair, and is lasted on the correct size. Without a structured marking system, factories face higher rejection rates, mismatched pairs, shade variation, and costly production delays.

This article explains why match marking systems are essential in modern footwear factories and explores the most effective methods used across global production lines.

Why Match Marking Matters in Footwear Production

Inconsistent or missing identification is one of the most common causes of disruption in stitching and lasting rooms. When components are not clearly marked, factories experience:

- Delays caused by missing or incorrect parts

- Higher rejection rates due to size and shade mismatch

- Poor shoe appearance and inconsistent fit

- Increased material waste and rework costs

Because natural materials—especially leather—vary in colour, grain, nap, and softness, match marking ensures visual consistency in finished footwear while maintaining production flow.

The Importance of Size Control Marking

Size differences between components are often difficult to judge visually, especially when multiple sizes are processed simultaneously. If wrongly sized sections are stitched together, the consequences can be serious.

Incorrect size matching may lead to:

- Poor fitting on the last

- Excess tension that causes material or construction failure

- Distorted shoe shape after de-lasting

- Reduced wearer comfort and customer dissatisfaction

For these reasons, clear size marking is not optional—it is a fundamental requirement for quality assurance in footwear production.

Pair and Shade Matching – Why It Is Essential

Some materials demand special attention during cutting and matching. Full-grain leathers, suedes, nubucks, and exotic skins naturally vary across the hide. To achieve a uniform appearance in finished shoes, factories rely on pair and shade marking systems.

These systems help to:

- Match components cut from similar areas of the hide

- Control differences in colour, grain pattern, and nap direction

- Ensure visual harmony between left and right shoes

In premium and fashion footwear, this practice becomes even more critical, as customers expect near-perfect visual consistency.

Posts you may like

Match Marking Systems Used in Footwear Factories

Modern footwear production uses a combination of traditional and advanced marking techniques. Each method serves a specific operational purpose.

Crayon Marking – Temporary Production Guidance

Crayon marking is traditional method which was widely used at the cutting stage. The cutter writes essential information—such as size, shade, or order reference—on the reverse side of the components before they leave the cutting room.

This method provides temporary identification that guides operators in the stitching preparation area. Once components move further into production, more permanent markings are usually added.

Key benefits include:

- Quick and flexible application

- No equipment investment

- Ideal for short-term identification

However, because it is temporary, crayon marking must always be supported by a permanent match marking system.

Colour Marking – Traditional Visual Coding

Colour marking is one of the oldest methods of component identification. Coloured inks or paints are applied to the cut edges of uppers to represent different sizes or fittings.

Although still used in some European factories, it is now less common in Asia due to the availability of more precise methods.

Colour marking helps by:

- Allowing instant visual recognition

- Enabling faster stacking of same-size components

- Reducing sorting time in stitching preparation

Its limitation lies in appearance control, as colour marks can sometimes be difficult to hide in finished footwear.

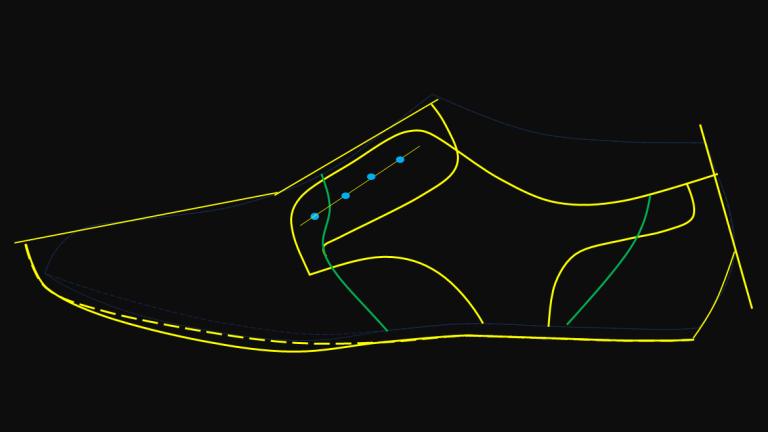

Notch Marking – Built-In Size Identification

Notch marking involves cutting a coded series of small indentations into the edges of components during the cutting process. These notches are part of the cutting knife design and typically represent size and sometimes left–right orientation.

Because the markings are built into the cutting tools, notch marking offers exceptional accuracy with no additional labour cost. Once knives are verified, the risk of marking errors is minimal.

However, the system allows only limited information to be conveyed and must be carefully designed to avoid visible marks on finished shoes.

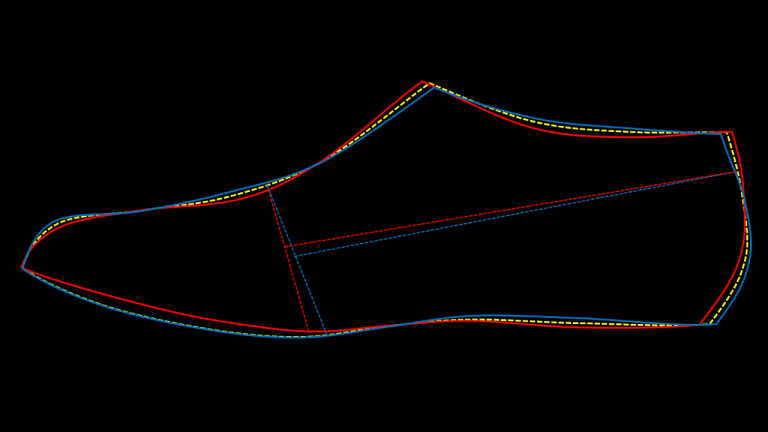

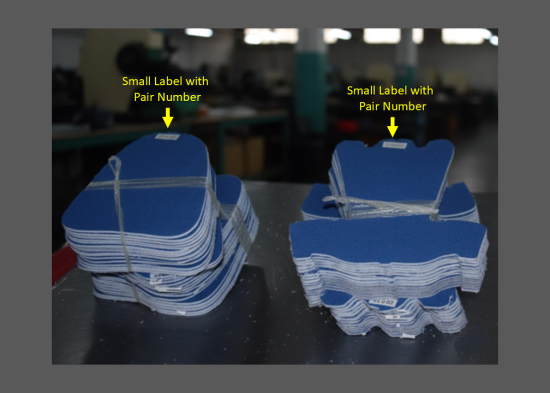

Individual Match Marking with Numbered Labels

In many Asian footwear factories, numbered label systems are the most reliable method for pair control. Each pair of uppers receives a unique number, and the same number is applied to every component belonging to that pair.

This ensures that:

- All matching parts remain together

- Stitching operators assemble the correct components

- Lasting rooms receive perfectly matched pairs

Number-based match marking is particularly effective in high-volume production where multiple styles and sizes run simultaneously.

Coloured Tapes for Pair Control

Some factories reinforce pair matching by stitching a small coloured tape into the topline of each upper once stitching is complete. Different colours represent different pairs.

This system is especially useful in the lasting and making rooms, where other identification marks may be hidden or removed during processing.

Coloured tapes act as a final safeguard against mismatching.

Machine Marking – Permanent Production Traceability

Machine marking represents the most advanced form of match marking. Using printing or digital coding systems, key information is applied directly onto components.

This method offers:

- High clarity and durability

- Excellent traceability throughout production

- Professional appearance for premium brands

Although it requires higher investment, machine marking is increasingly used in factories that focus on automation, compliance, and high-end quality standards.

Best Practices for an Effective Match Marking System

A strong match marking strategy combines method selection with process discipline. To achieve consistent results, footwear manufacturers should:

- Apply markings immediately after cutting

- Standardize codes across cutting, stitching, and lasting

- Train operators in shade matching and size control

- Use permanent marking for critical identification

- Conduct routine audits of marking accuracy

When match marking becomes part of the factory culture, quality issues decline and production efficiency improves.

Conclusion

Match marking is far more than a simple identification task—it is a foundation of quality control in footwear manufacturing. From ensuring correct size and perfect pairing to maintaining visual consistency, an effective marking system directly impacts productivity, cost control, and customer satisfaction.

By combining traditional techniques such as crayon, colour, and notch marking with modern systems like numbered labels, coloured tapes, and machine marking, factories can build a robust production control framework. In today’s competitive footwear industry, a well-designed match marking system is not just good practice—it is a strategic advantage.