Footwear Manufacturing Insights: Correct Height of the Workplace & Good Heel Grip

Reading Time : 3 Minutes

This article is prepared by extracting and interpreting the technical guidance shown in the provided reference images and aligning it with earlier blog-writing instructions used for FootwearEdge. The focus is on ergonomics in footwear manufacturing and upper design techniques that improve heel grip—both critical for productivity, quality, and wearer comfort.

Correct Height of the Workplace

To prevent fatigue at the workplace, the working height must be correctly matched to the specific task being performed. Poor workstation height leads to unnecessary strain on the arms, shoulders, back, and legs—ultimately reducing productivity and increasing operator fatigue.

Key Ergonomic Principles

The optimal working position is achieved when:

- The forearms of the operator are inclined downward by approximately 15° while performing the task.

- This angle allows the shoulders to remain relaxed and avoids excessive lifting or bending of the arms.

- Whether the employee is standing or seated, the working surface height should allow this natural forearm inclination.

In seated workstations:

- The seat height must be adjustable so that the forearms still maintain the recommended downward angle.

- The footrest or platform should allow the feet to incline upwards by around 15°, providing proper leg support and circulation.

Why Correct Height Matters in Footwear Factories

Operations such as cutting, skiving, stitching, pressing, and assembly are repetitive in nature. Incorrect workstation height causes:

- Faster muscle fatigue

- Reduced precision during operations

- Increased risk of long-term musculoskeletal disorders

Adhering to proper ergonomic height guidelines has a direct positive impact on productivity, especially in press work and precision operations, where operator stability and control are essential.

Posts you may like

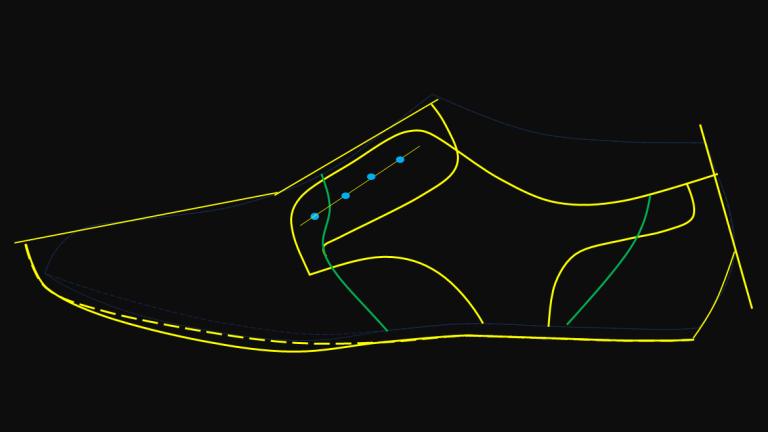

Good Heel Grip – Upper Design Insight

Achieving a secure heel grip is critical for footwear comfort, fit, and performance. One effective yet often overlooked technique lies in how the upper is prepared before the counter is stitched.

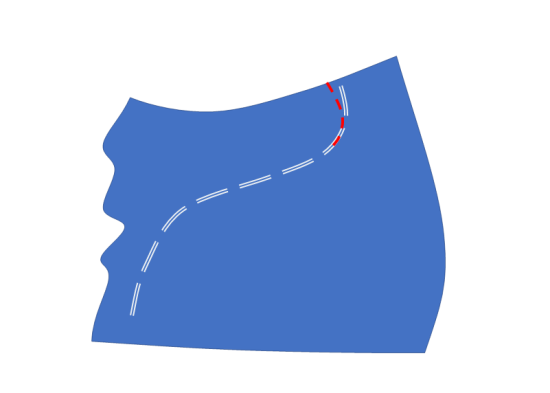

Technique Explained

To obtain a really good grip at the top edge of the upper:

- The marked line at the heel area can be slightly canted inward at the top.

- This adjustment is done prior to stitching the counter.

- The inward canting allows the upper to naturally wrap and grip the heel more securely once lasting and finishing are completed.

The reference illustration clearly indicates this inward movement using an arrow, highlighting the controlled shaping of the upper edge.

Benefits of This Method

- Improved heel lock without excessive padding

- Better fit consistency across sizes

- Reduced heel slippage during wear

- Enhanced wearer comfort, especially in formal and performance footwear

This is a simple pattern-level adjustment that delivers significant functional benefits without additional material cost.

Practical Takeaway

Both topics highlighted in this article—correct workplace height and upper design for heel grip—demonstrate how small, well-understood technical details can make a major difference in:

- Operator efficiency

- Product quality

- Long-term comfort and durability of footwear

For footwear factories aiming to improve productivity and reduce operator fatigue, ergonomics should be treated as a process standard, not an optional improvement. Similarly, thoughtful upper design details contribute directly to fit and consumer satisfaction.