Mold in the Footwear Industry: Complete Scientific and Practical Guide

Estimated Reading Time: ~ 8 minutes

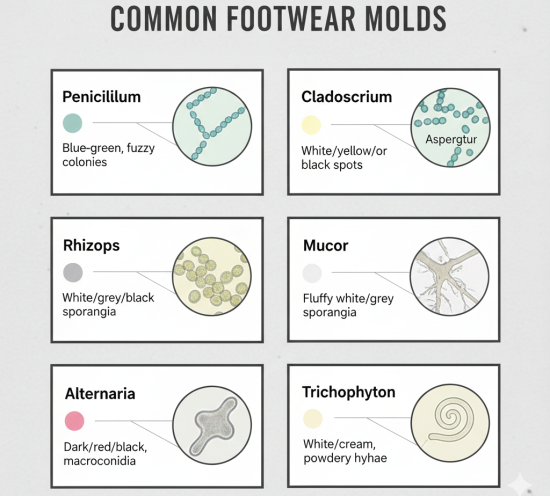

Scientific Classification: Types of Mold Found in Footwear

| Mold Species | Common Name | Colour on Shoes | Preferred Material | Toxin Produced | Health Risk Level |

|---|---|---|---|---|---|

| Aspergillus niger | Black mold | Jet black | Genuine leather, PU, glue, cardboard | None (usually) | Medium |

| Aspergillus flavus / parasiticus | Yellow-green mold | Yellow → Green | Leather, cotton lining, starch | Aflatoxin B1 (carcinogenic) | Very High |

| Penicillium spp. | Green/blue mold | Turquoise-green | Leather, textiles, paper | Mycophenolic acid | High |

| Rhizopus nigricans | Bread mold / White fuzzy | White → Grey | Leather, rubber, cardboard | None | Low |

| Alternaria alternata | Dark spot mold | Brown-black | Synthetic mesh, EVA, rubber | Alternariol | Medium |

| Trichoderma spp. | Fast-growing green | Bright green | Wood pallets, cardboard, glue | Trichothecenes | High |

| Cladosporium spp. | Olive-black mold | Dark olive | Rubber outsoles, synthetic leather | None | Low |

| Fusarium spp. | Pink-red mold | Pink → Purple | Cotton canvas, insoles | Fumonisins | High |

Good Mold vs Harmful Mold

| Beneficial Molds | Application |

|---|---|

| Penicillium roqueforti / camemberti | Blue cheese production |

| Penicillium chrysogenum | Produces penicillin (antibiotic) |

| Aspergillus oryzae / sojae | Soy sauce, miso, sake fermentation |

| Rhizopus oligosporus | Tempeh production |

→ These are never found in footwear factories – any visible mold on shoes is harmful.or warehouses

Pro Tip: If you can see mold with the naked eye, it has already released millions of spores. Immediate isolation is mandatory.

How Mold Grows – Step-by-Step Lifecycle on Footwear Materials

- Spore landing (invisible) – spores are always in the air (10,000–100,000 per m³ in tropical factories)

- Germination (6–12 hours) – when RH > 62 % and temperature 25–35 °C

- Hyphae growth (24–48 hours) – thread-like structures penetrate leather pores

- Visible colony (48–96 hours) – white fuzzy → coloured spores

- Sporulation (5–10 days) – billions of new airborne spores released

Preferred Materials & Formation Sites

| Material | Mold Affinity | Typical Formation Location |

|---|---|---|

| Genuine bovine leather | Extremely high | Upper, lining, insole, tongue |

| PU coated leather | Very high | Creases, stitching holes |

| Cardboard shoe boxes | Extremely high | Inside walls, bottom |

| EVA & Phylon midsoles | Medium | When contaminated with sweat |

| Cotton canvas | High | Linings, laces |

| Rubber outsoles | Low | Only if organic dirt or sweat present |

| Nylon / Polyester mesh | Medium | When starch sizing is present |

Documented Damage & Case Studies

Public case studies & reports:

- SGS 2024 Footwear Mold Report → https://www.sgs.com/en/webinars/2021/11/mold-prevention-in-the-softlines-supply-chain

- Bureau Veritas Consumer Products 2023 White Paper → https://www.prnewswire.com/news-releases/new-mold-prevention-breakthrough-by-bureau-veritas-has-potential-to-significantly-reduce-losses-for-leather-and-textile-manufactures-184219911.html

Average global rejection rate due to mold in footwear containers: 3.8 % (SGS & Bureau Veritas 2024 data)

Best Practice: Require every supplier to submit a “Mold Prevention Declaration” with every shipment, including RH charts from warehouse and container.

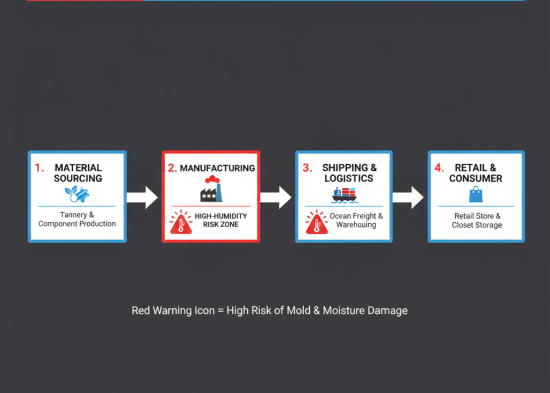

Critical Control Points in the Footwear Supply Chain

| Stage | Typical RH | Risk Level | Common Failure Mode |

|---|---|---|---|

| Raw material warehouse | 75–90 % | High | Leather rolls stored on wooden pallets |

| Production floor | 65–85 % | Very High | Sweat from workers + no filtered compressed air |

| Finished goods warehouse | 70–95 % | Critical | No dehumidification during rainy season |

| Sea freight container | 85–100 % | Extreme | Condensation due to day-night temperature swing |

Professional Prevention Protocol – Industry Standard

Warehouse & Factory Environment Control

- Maintain RH ≤ 55 % (≤ 50 % recommended)

- Use only plastic pallets (never wood) – minimum 15 cm off floor, 50 cm from walls

- Daily calibrated temperature & humidity logging

- Install Humidifiers to maintain required RH

Pro Tip: Install wireless IoT sensors (e.g., Sensirion or ELPRO systems) that send SMS alerts when RH > 57 % for more than 6 hours.

Production Line Controls

- Add EU REACH & EPA-registered anti-mold additives to water-based glues (0.3–0.8 %)

- Control moisture content of all paper materials ≤ 8 % before packing

- Mandatory full-finger glove policy during final packing

Leading Professional Solutions

SGS (Global Testing and Certification Leader)

Official website: https://www.sgs.com/en/services/mold-prevention

Key products & services:

- Advanced laboratory testing for mycotoxins and spore detection

- Comprehensive mold prevention testing for material resistance and chemical agent compliance

- On-site factory assessments measuring moisture, humidity, ventilation and housekeeping

- Training programs on mold causes and prevention strategies

- Supply chain audits to minimize financial losses from recalls

Bureau Veritas (Worldwide Inspection and Audit Specialist)

Official website: https://www.cps.bureauveritas.com/needs/extended-storage-risk-mitigation-program Key products & services:

- On-site audits with CAPA (Corrective and Preventive Actions) recommendations

- Extended Storage Risk Mitigation Program for mold contamination checks in warehouses

- Factory Mold Prevention Program including building assessments, production area maintenance and chemical control

- Product inspections for mold, insects and moisture in cartons and pallets

- Performance and chemical testing aligned with REACH, CPSIA and client RSLs

BSN Fresh&Biodry® (China & Southeast Asia Market Leader)

Official website: https://bsn-group.com/

Key products:

- Full factory mold audit + RCA report + staff training

- AEM9988 anti-mold spray (direct shoe treatment)

- AEM9988-3 water-based warehouse space disinfectant

- Anti-mold wrapping paper & LDPE bags (6-month protection when sealed)

- Container desiccant poles (CaCl₂ + super-absorbent polymer)

Micro-Pak Distribution Ltd (Global Packaging Innovator)

Official website: https://www.micropakltd.com

Key products & services:

- On-site training & certification program

- Micro-Pak® Enhanced Anti-Mold Stickers & Sheets (EPA registered, bluesign® approved)

- Micro-Pak® Container Desiccant Poles (up to 350 % absorption)

- Digital Mold Risk Assessment Platform

Other Leading Solutions: Clariant AG and Multisorb Technologies

Clariant AG Official website: Key products & services:

- Advanced anti-mold chips and moisture control solutions for packaging

- Sustainable formulations for food, pharma and footwear applications

- Integrated active packaging with mold inhibitors

Multisorb Technologies Official website: https://www.multisorb.com/ Key products & services:

- Smart anti-mold desiccants and sorbents for containers

- Data analytics-enabled monitoring systems

- Customized solutions for electronics and textiles alongside footwear

Best Practice: Combine SGS or Bureau Veritas audits for compliance with BSN/Micro-Pak products for daily prevention, and Clariant/Multisorb for advanced packaging. This multi-vendor approach ensures comprehensive coverage and >99 % mold-free outcomes for Tier-1 brands in 2025.

UV-C Technology for Mold Control

| Method | Effectiveness | Limitations |

|---|---|---|

| UV-C conveyor tunnels | 99.99 % surface kill | No penetration into boxes or leather pores |

| Autonomous UV-C warehouse robots | 99.9 % on exposed surfaces | High cost, requires empty warehouse |

| UV-C + ozone combination | Extremely high | Ozone residue regulations in EU/US |

Pro Tip: Use UV-C only as a supplementary measure. Primary defense must always be humidity control + chemical prevention.

Complete Footwear Mold Prevention Checklist (Factory Audit Standard)

- Warehouse RH ≤ 55 % year-round

- All paper materials moisture ≤ 8 % max (tested with moisture meter)

- Plastic pallets only

- Anti-mold paper or stickers inside every shoe box

- Minimum 10 × 1.2 kg container desiccant poles per 40 ft container

- Temperature & RH data logger in warehouse & every container

- No bare-hand contact with finished shoes

- Monthly ATP (Adenosine Triphosphate) swab + mold spore count testing

- Install Humidifiers to maintain RH

Downloadable checklist PDF: https://www.micropakltd.com/resources/mold-prevention-checklist

Conclusion

Mold remains the single largest preventable cause of quality claims and chargebacks in the footwear industry. Factories and brands that implement comprehensive, multi-layer prevention systems (environmental control + SGS/Bureau Veritas audits + BSN Fresh&Biodry products + Micro-Pak sheets & poles + Clariant/Multisorb innovations + strict protocols) consistently achieve mold rejection rates below 0.2 % – a 15–20× improvement.

For factory audits, product trials or customized prevention programs contact:

SGS → www.sgs.com/en/services/mold-prevention

Bureau Veritas → www.bureauveritas.com/cps

BSN Fresh&Biodry → www.gzbsn.com

Micro-Pak → www.micropakltd.com

Clariant AG → www.clariant.com

Multisorb Technologies → www.multisorb.com