Adhesive Safety Essentials: Guidelines for Safe Handling and Toluene-Free Options

Introduction to Adhesive Safety Guidelines in Everyday Projects

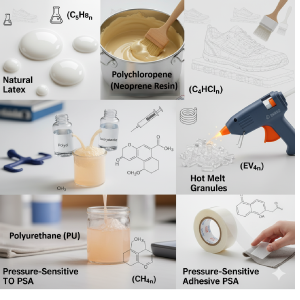

Adhesives play a vital role in applications ranging from crafting to construction, ensuring seamless bonding and project continuity. However, solvents in these products—such as toluene, xylene, and MEK—can pose health risks if not managed properly under adhesive safety guidelines. By understanding these hazards, including Threshold Limit Values (TLVs), and adopting regulatory advancements, users implement safer practices to avoid disruptions. This guide explores key adhesive safety guidelines from established manuals, focusing on hazards, first aid, storage, and eco-friendly shifts toward toluene-free formulations.

Key Solvent Hazards and Classifications in Adhesive Safety Guidelines

Overview of Common Solvent Risks

Solvents in adhesives present health threats via inhalation, skin contact, or ingestion, with risks varying by type and exposure level. For example, toluene causes dizziness and nausea through vapors, while MEK (methyl ethyl ketone) irritates mucous membranes and can depress the central nervous system with prolonged exposure. Additionally, other solvents like butyl acetate (mild skin defatting), butanol (eye and throat irritation), and carbon tetrachloride (liver and kidney damage) add to the hazard profile.

Detailed Solvent Effects

Furthermore, chronic exposure to benzene may damage the central nervous system, and acetone can dry skin or cause headaches. Formalin (formaldehyde) leads to respiratory sensitization, ethylene glycol to kidney toxicity, melamine to bladder issues in high doses, methanol to vision impairment, and plasticizers like tricresyl phosphate to nerve damage. Isocyanates, common in polyurethane adhesives, trigger asthma-like symptoms and sensitization, while DBT (dibutyltin) poses organ toxicity risks. These hazards are classified by concentration: low for short exposures, higher in unventilated spaces. Moreover, combustible solvents like ethyl acetate increase fire risks.

Safety Classifications and TLVs

Adhesive safety guidelines categorize solvents by relative safety. Relatively safe solvents include acetone, butyl acetate, amyl acetate (normal), heptane (normal), light petroleum, ethanol, isopropyl alcohol, methyl acetate, ethyl acetate, propyl acetate, cyclohexane, and dichloromethane—these offer lower toxicity with proper handling. Slightly hazardous solvents encompass methanol, MEK, toluene, xylene, white spirit, trichloroethylene, perchloroethylene, formalin, ethylene glycol, and melamine, requiring stricter controls due to potential irritation or systemic effects.

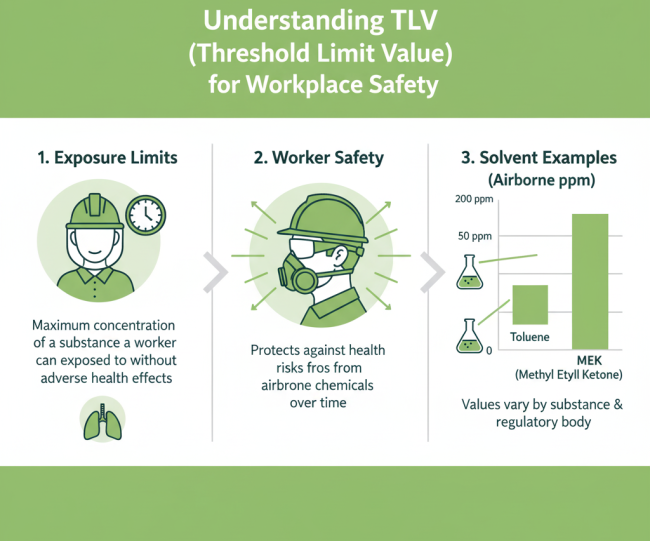

Threshold Limit Values (TLVs) represent the maximum airborne concentration (in ppm or mg/m³) workers can handle daily without adverse effects, as set by the American Conference of Governmental Industrial Hygienists (ACGIH). For instance, toluene’s TLV is 20 ppm, MEK’s is 200 ppm, and acetone’s is 500 ppm. Monitoring TLVs in workspaces prevents overexposure, aligning with adhesive safety guidelines to maintain health.

Green Revolution Impact

In addition, the green revolution has shifted adhesive formulations toward toluene-free options compliant with Restricted Substances Lists (RSL) and REACH regulations, limiting toluene to under 0.1% in Europe. This reduces risks while preserving bonding strength, allowing selection of low-VOC alternatives for sustainable project continuity.

The table below illustrates selected solvents, their effects, and regulatory notes under adhesive safety guidelines:

| Solvent | Inhalation Effects | Skin Contact Effects | Ingestion Risks | Regulatory Status (REACH/RSL) & TLV Notes |

|---|---|---|---|---|

| Toluene | Dizziness, nausea | Dryness, irritation | Stomach pain, vomiting | Restricted >0.1%; toluene-free in latest products; TLV: 20 ppm |

| Xylene | Headache, respiratory issues | Defatting of skin | Nausea, abdominal cramps | Monitored; alternatives encouraged; TLV: 100 ppm |

| Acetone | Irritation of mucous membranes | Mild irritation | Gastrointestinal upset | Generally permitted; TLV: 250 ppm |

| Benzene | Drowsiness, confusion | Dermatitis | CNS depression | Highly restricted; phased out; TLV: 0.5 ppm |

| MEK (Methyl Ethyl Ketone) | Headache, narcosis | Irritation | Vomiting, abdominal pain | Permitted with limits; TLV: 200 ppm |

| Butyl Acetate | Throat irritation, drowsiness | Mild defatting | Nausea | Relatively safe; TLV: 50 ppm |

| Butanol | Eye/throat irritation, headache | Absorption, dermatitis | CNS depression | Slightly hazardous; TLV: 20 ppm |

| Carbon Tetrachloride | Liver/kidney damage, dizziness | Defatting, absorption | Vomiting, coma | Restricted; TLV: 5 ppm |

| Formalin (Formaldehyde) | Respiratory irritation, sensitization | Burns, allergies | Severe GI damage | Slightly hazardous; TLV: 0.3 ppm ceiling |

| Ethylene Glycol | Kidney toxicity, CNS effects | Mild irritation | Metabolic acidosis | Slightly hazardous; TLV: 25 ppm aerosol |

| Melamine | Bladder irritation (chronic) | Low absorption | GI upset | Slightly hazardous; no specific TLV |

| Methanol | Vision impairment, headache | Absorption, dryness | Blindness, acidosis | Slightly hazardous; TLV: 200 ppm |

| Tricresyl Phosphate | Nerve damage, paralysis | Absorption | Neurotoxicity | Restricted in plasticizers; no TLV |

| DBT (Dibutyltin) | Organ toxicity, irritation | Skin absorption | GI distress | Restricted; no specific TLV |

| Isocyanates | Asthma, sensitization | Irritation | Respiratory distress | Highly regulated; TLV varies (e.g., TDI: 0.005 ppm) |

This breakdown emphasizes the critical role of adhesive safety guidelines in managing solvent risks.

First Aid Measures in Adhesive Safety Guidelines

Immediate action minimizes impacts from exposures, as per adhesive safety guidelines. For eye contact with solvents like MEK or formalin, flush eyes with water for 15 minutes. Treat skin exposure—common with plasticizers or isocyanates—by washing with soap and water, seeking medical help if irritation lingers.

For inhalation of vapors from toluene or carbon tetrachloride, move to fresh air and administer oxygen if needed. Avoid inducing vomiting for ingestion; offer water or milk and get urgent care. These steps, informed by safety data, restore continuity quickly, especially with low-TLV solvents.

Allergic reactions to isocyanates or melamine may need antihistamines and professional consultation. Adhering to adhesive safety guidelines reduces downtime effectively.

Safe Storage and Handling Under Adhesive Safety Guidelines

Adhesive safety guidelines mandate storage in cool, dry spots away from sunlight and flames, with sealed containers to curb vapor leaks. Wear gloves and eye protection during handling to prevent splashes from hazardous solvents like butanol or tricresyl phosphate.

Ventilate work areas during application, clean spills with absorbents promptly. Use precise tools like squeeze bottles to minimize waste and exposure. Verify material compatibility, avoiding metal for reactive solvents, and ground equipment in large setups to prevent sparks.

These practices, enhanced by green, toluene-free adhesives, protect users and ensure smooth project timelines.

Conclusion: Prioritizing Adhesive Safety Guidelines for Lasting Success

Adhesive safety guidelines form the bedrock of safe bonding, mitigating solvent hazards through awareness of TLVs, first aid preparedness, and careful handling. The green revolution propels toluene-free, RSL- and REACH-compliant products, reducing risks from substances like isocyanates and DBT while boosting sustainability. Professionals and hobbyists gain from these guidelines, sourced from detailed manuals and updated for modern innovations, ensuring uninterrupted project execution.

Embrace safe adhesives today!