Shoe Lasts Explained: Their Role in Footwear Design

What Is a Shoe Last and Why It Matters

A shoe last is a 3D mold that replicates the shape of a human foot. It serves as the foundation for shoe construction, influencing everything from fit and comfort to style and performance. Whether you’re designing casual sneakers or formal dress shoes, the last determines how the shoe hugs the foot and how it looks on the shelf.

Materials Used in Shoe Last Manufacturing

Shoe lasts are made from different materials depending on the production method and design needs:

- Wood: Traditionally used in handmade and bespoke shoemaking. Maple and hornbeam are popular for their durability and ease of carving.

- Plastic: High-density polyethylene (HDPE) and polypropylene are common in mass production due to their lightweight and moldability.

- Aluminium: Used in industrial settings for heat molded Shoes Manufacturing and precision shaping.

These materials affect the durability, flexibility, and cost of the last—and ultimately, the shoe.

Types of Shoe Lasts and Their Applications

Different footwear styles require different last shapes. Here are the most common types:

Shoe lasts are made from different materials depending on the production method and design needs:

- Wood: Traditionally used in handmade and bespoke shoemaking. Maple and hornbeam are popular for their durability and ease of carving.

- Plastic: High-density polyethylene (HDPE) and polypropylene are common in mass production due to their lightweight and moldability.

- Aluminium: Used in industrial settings for heat molded Shoes Manufacturing and precision shaping.

These materials affect the durability, flexibility, and cost of the last—and ultimately, the shoe.

|

Type of Last |

Best For |

Key Features |

|

Standard Last |

Casual and |

Balanced toe |

|

Boot Last |

Ankle boots, |

Extended |

|

Sandal Last |

Open footwear |

Minimal |

|

Heel Last |

High heels |

Elevated arch |

|

Orthopaedic Last |

Medical and |

Customized |

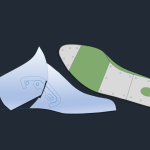

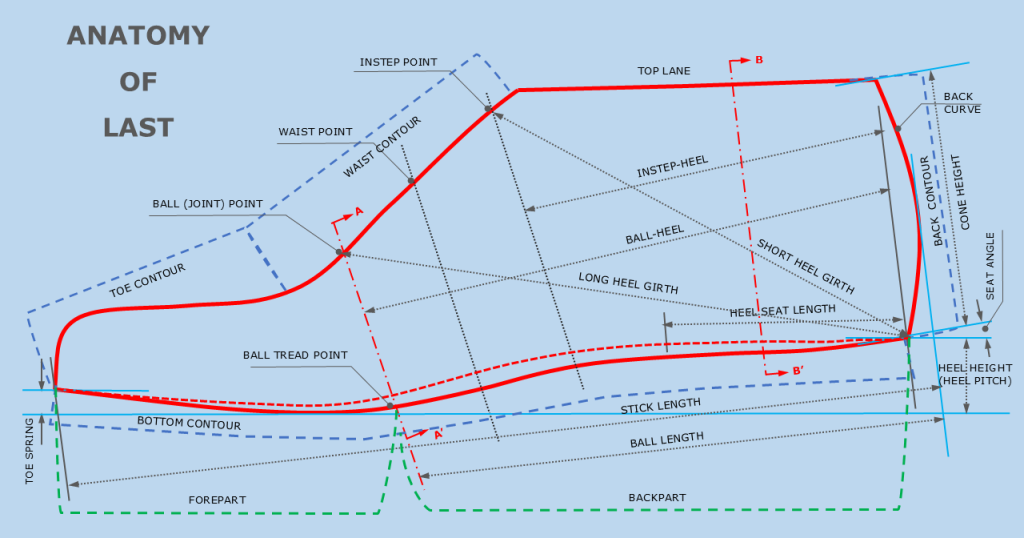

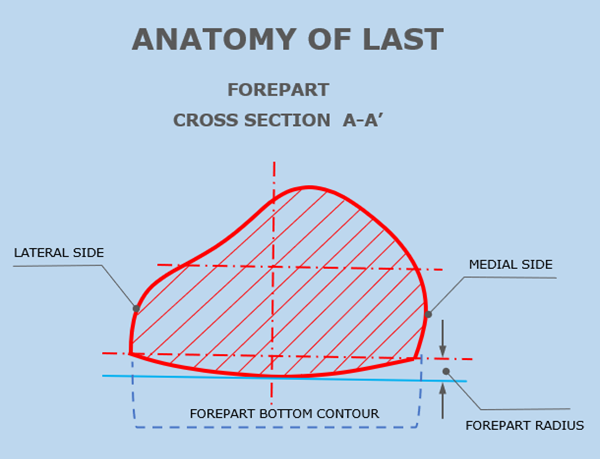

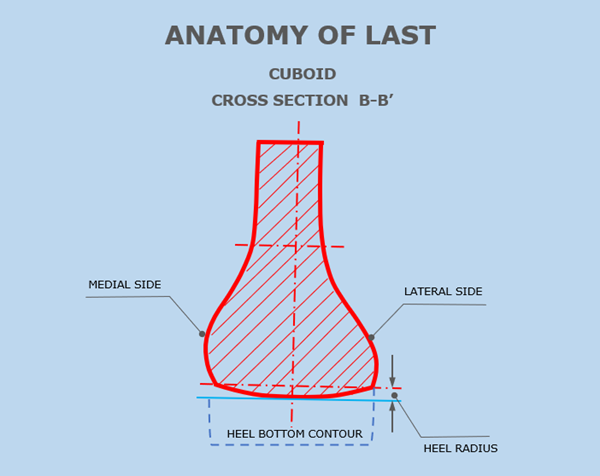

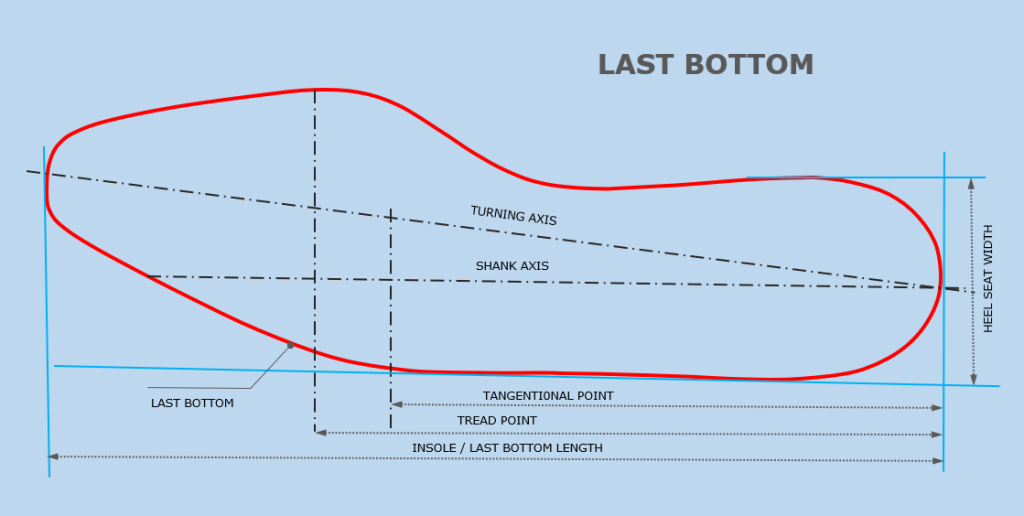

Understanding the Anatomy of a Shoe Last

A shoe last is more than just a mold—it’s the blueprint of fit, comfort, and style. To truly grasp how lasts influence footwear design, it’s essential to understand their anatomical components. Below is a labelled diagram of a hinged shoe last, followed by a breakdown of each part:

Key Parts of the Shoe Last

|

Part |

Description |

|

Toe Box |

The front-most section that shapes the toe area of the shoe. Determines toe room and style (e.g., round, pointed). |

|

Instep |

The raised area over the arch of the foot. Crucial for fit and support, especially in dress shoes and boots. |

|

Ball Width |

The widest part of the last, corresponding to the ball of the foot. Influences width sizing and forefoot comfort. |

|

Waist |

The narrow middle section between the ball and heel. Affects arch support and overall silhouette. |

|

Throat Line |

The curved line that defines the shoe’s opening. Impacts vamp design and ease of entry. |

|

Heel Seat |

The flat area where the heel rests. Determines heel height and stability. |

|

Backpart |

The rear section that shapes the heel counter and back of the shoe. Provides structure and alignment. |

Why These Parts Matter

Each component plays a role in how the shoe fits, feels, and performs. For example:

- A deeper toe box accommodates wider feet or orthopaedic needs.

- A well-contoured instep ensures snugness without pressure.

- The waist and heel seat influence posture and gait alignment.

Understanding these elements helps designers, manufacturers, and consumers make informed choices—whether customizing lasts or selecting ready-made footwear.

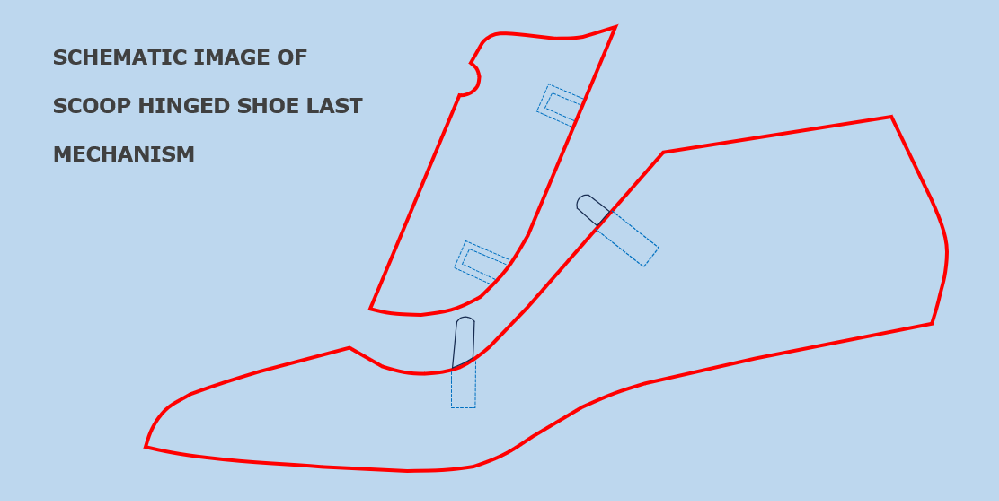

Understanding Feature of Shoe Lasts

One of the most important features of a last is whether it is solid or hinged. Understanding this difference is key to appreciating the art and engineering behind footwear.

A solid last is a single, unmovable piece. It’s the most basic type of last and is typically used for open-style footwear like sandals, mules, or slippers.

A hinged last is a more advanced and versatile tool. Unlike a solid last, it is made of two or more parts connected by a metal hinge and a spring mechanism. This design allows the last to be collapsed, shortened, or otherwise manipulated to make removal from a closed-toe shoe significantly easier.

These are especially useful in sample development and complex shoe constructions. Will discuss elaborately on each hinge in next Blog

Functions of a Shoe Last in Shoemaking

The shoe last plays a central role in:

- Shaping the upper material during lasting

- Defining shoe size, width, and toe shape

- Supporting sole attachment and pattern making

- Ensuring anatomical accuracy and wearer comfort

Without a well-designed last, even the most stylish shoe can fail in fit and function.

How to Choose the Right Shoe Last

Selecting the correct last depends on several factors:

- Footwear category: Sports, formal, casual, orthopaedic

- Target audience: Gender, age, regional foot shapes

- Design goals: Style vs. comfort priorities

- Production method: Handmade vs. automated

A well-matched last ensures better fit, durability, and customer satisfaction.

Determining Shoe Lasts Based on Foot Anatomy

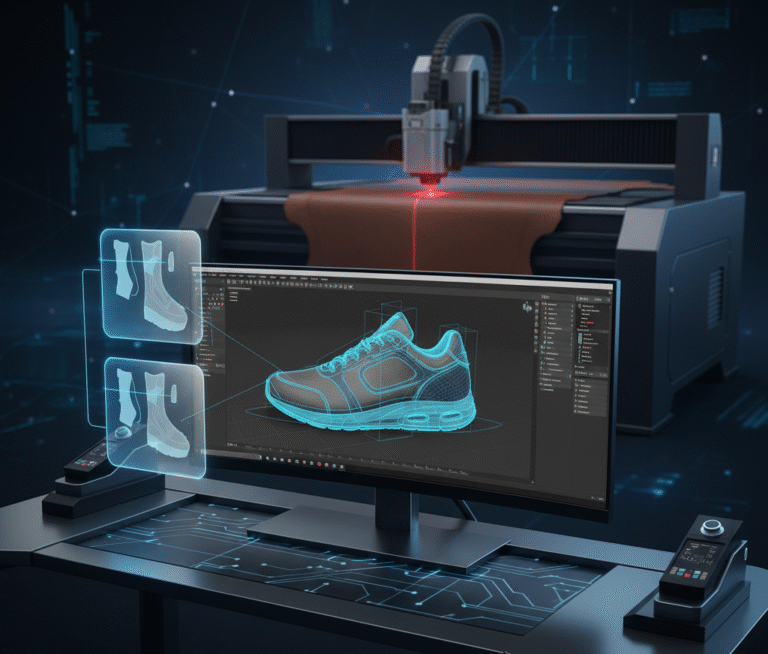

In custom shoemaking and advanced design, lasts are tailored using:

- Foot measurements: Length, width, arch height, instep girth

- 3D foot scanning: For precision modelling and digital last creation

- Foot impressions: Used in orthopaedic and bespoke footwear

This ensures biomechanical accuracy and optimal fit.

Why Shoe Lasts Are Crucial in Footwear Manufacturing

The shoe last is the blueprint of every shoe. Its importance includes:

- Defining the shoe’s structure and silhouette

- Ensuring consistency across production batches

- Influencing comfort, performance, and aesthetics

- Acting as a reference for designers and technicians

Final Thoughts

Shoe lasts are the silent architects behind every great pair of shoes. From shaping the design to ensuring comfort and performance, they are indispensable in footwear manufacturing. Whether you’re crafting by hand or designing for mass production, understanding the anatomy and function of shoe lasts is key to creating shoes that truly fit.